Microporous polymer-nano-metal particle catalyst and its preparation method and use

A technology of nanometer metal particles and microporous polymers, applied in the direction of carbon compound catalysts, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve environmental pollution and other problems, and achieve improved catalytic efficiency , increase active sites, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

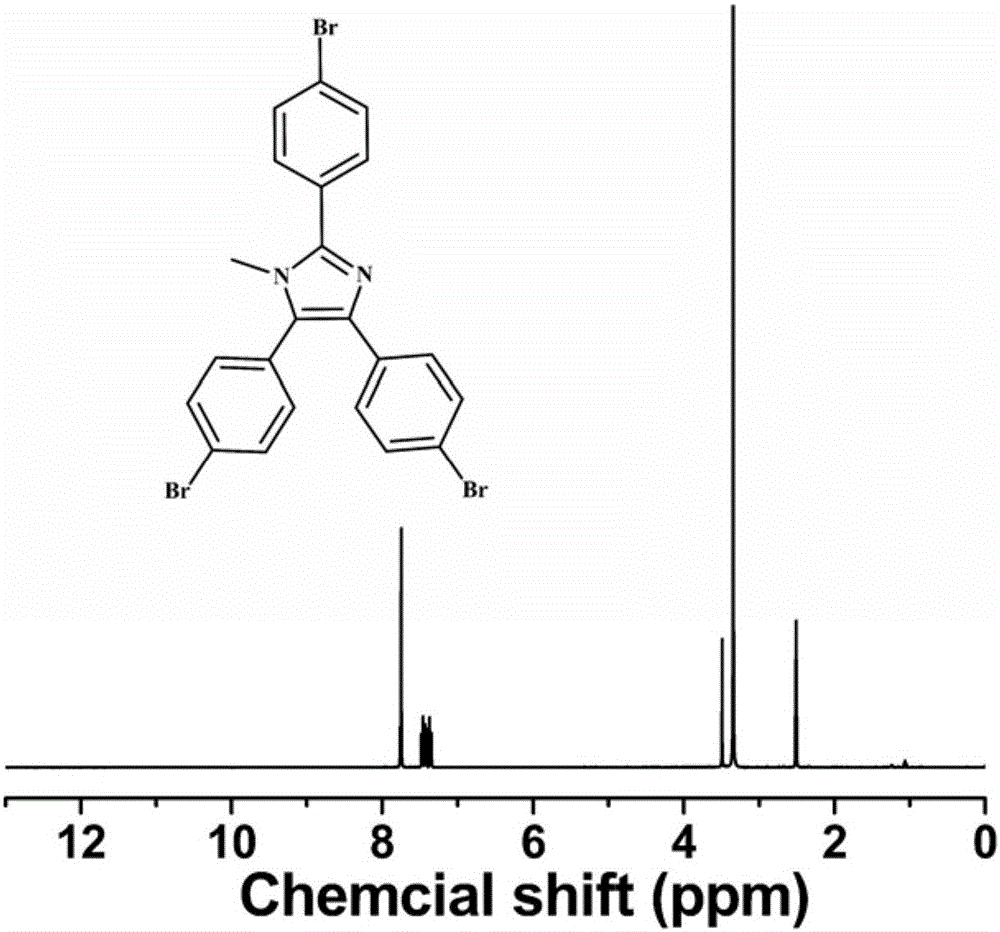

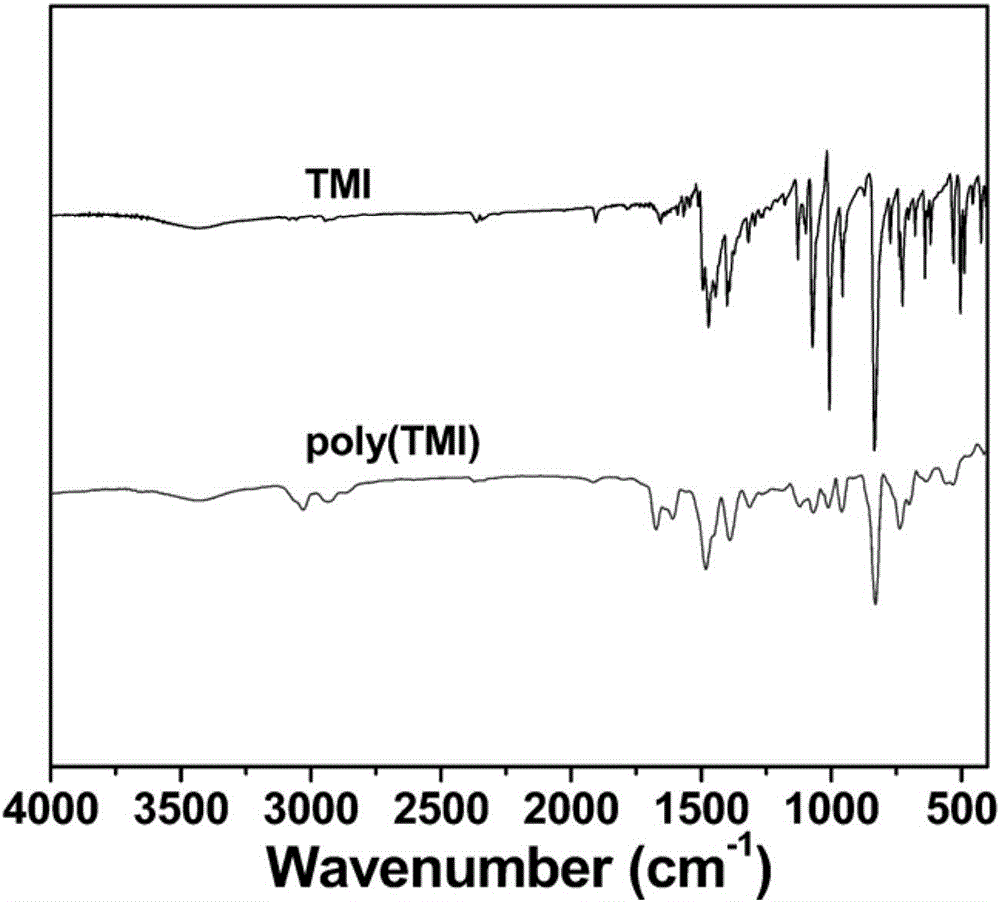

[0063] Synthesis of microporous polymer poly(TMI) in N 2 in a protected glove box. Weigh 0.55 g of monomer 2,4,5-tris(4-bromophenyl)-1-methylimidazole (TMI) containing bromine-substituted triaryl imidazole group, bis(1,5-cyclooctadiene ) Nickel (0) 1g, 2,2'-bipyridine 0.4g, 1,5-cyclooctadiene 0.6g and refined DMF dewatered 63mL were added to a single-necked round bottom flask, and reacted at 80°C for 72h to obtain dark purple suspended solids. After cooling down to room temperature, concentrated hydrochloric acid was added until the mixture in the flask became a milky white suspension. Filter with suction and wash with 30% NaOH aqueous solution until the pH of the filtrate is 7. The filter cake was washed with dichloromethane (3×20ml), methanol (3×20ml) and petroleum ether (3×20ml) successively, and vacuum-dried at 80°C for 12 hours to obtain a light yellow powdery solid, the microporous polymer poly(TMI ) 0.29 g.

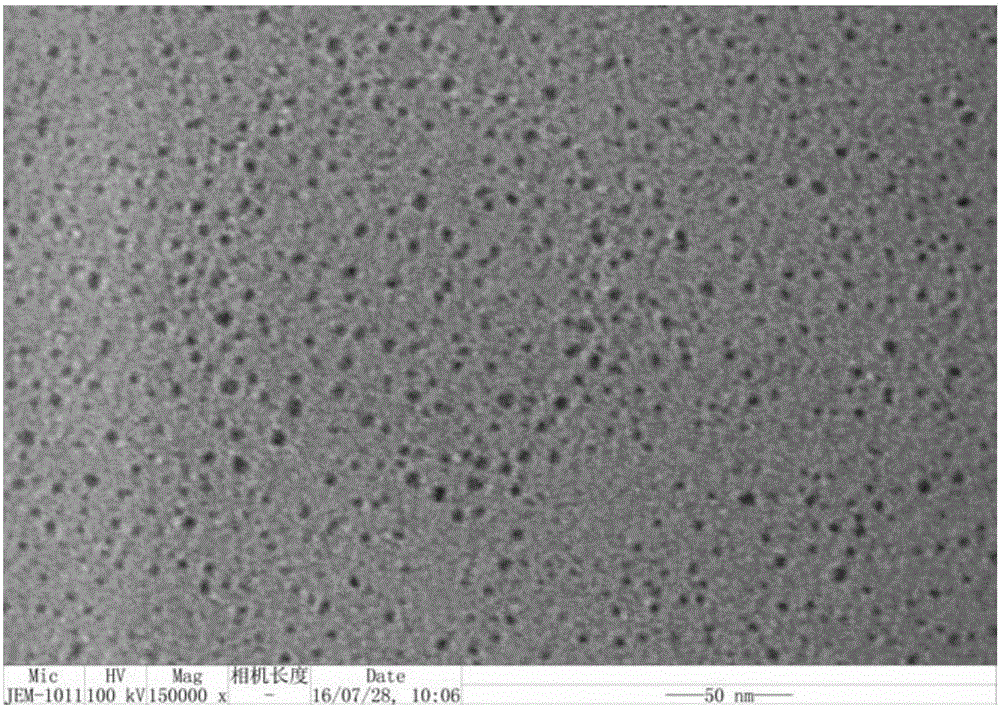

[0064] The resulting poly(TMI) was dissolved in 10 mL of...

Embodiment 2

[0067] Microporous polymer poly(THI) was synthesized in N 2 in a protected glove box. Weigh 0.5 g of monomer 2,4,5-tris(4-bromophenyl)-1-H-imidazole (THI) containing bromine-substituted triaryl imidazole group, bis(1,5-cyclooctadiene ) Nickel (0) 1g, 2,2'-bipyridine 0.4g, 1,5-cyclooctadiene 0.6g and refined DMF dewatered 63mL were added to a single-necked round bottom flask, reacted at 80°C for 72h to obtain a deep purple suspension things. After cooling down to room temperature, concentrated hydrochloric acid was added until the mixture in the flask became a milky white suspension. Filter with suction and wash with 30% NaOH aqueous solution until the pH of the filtrate is 7. The filter cake was washed with dichloromethane (3×20ml), methanol (3×20ml) and petroleum ether (3×20ml) successively, and vacuum-dried at 80°C for 12 hours to obtain a yellow powdery solid, the microporous polymer poly(THI). 0.26g.

[0068] The resulting poly(THI) was dissolved in 10 mL of DMF, and ...

Embodiment 3( application Embodiment 1

[0070] Get bromobenzene 0.26mL (2.5mmol), phenylboronic acid 460mg (3.77mmol), salt of wormwood 3g (21.7mmol), the microporous polymer-nanometer palladium catalyst 0.5mmol of embodiment 1, H 2 O 10mL, put in a 10mL centrifuge tube, reflux at 100°C, and react for 30min. After the reaction, centrifuge at 10,000 rpm, collect the supernatant, extract with ethyl acetate, and determine the reaction yield of the organic layer by high performance liquid chromatography (HPLC). The lower precipitate in the centrifuge tube was washed with ethanol and centrifuged more than 5 times to remove residual phenylboronic acid and bromobenzene; then washed with distilled water and centrifuged more than 5 times to remove potassium carbonate in the centrifuge tube to achieve Recovery of microporous polymer-nanopalladium catalysts. The recovered microporous polymer-nanometer palladium catalyst is reused to catalyze the coupling reaction of bromobenzene and phenylboronic acid, and the above operation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com