Technology of chitosan microsphere clear pineapple juice

A technology of chitosan microspheres and pineapple juice, which is applied in food science and other directions, can solve the problems of low nutrient retention rate and pesticide residues in fruit juice, and achieve the effects of improving water solubility, aggravating loss and promoting clarification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

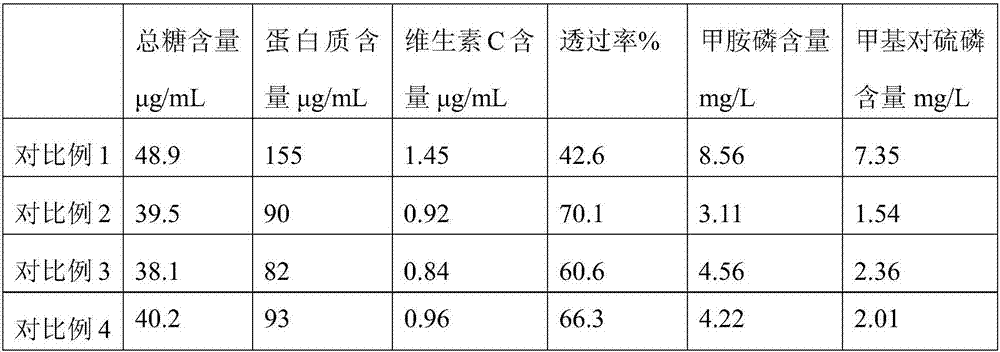

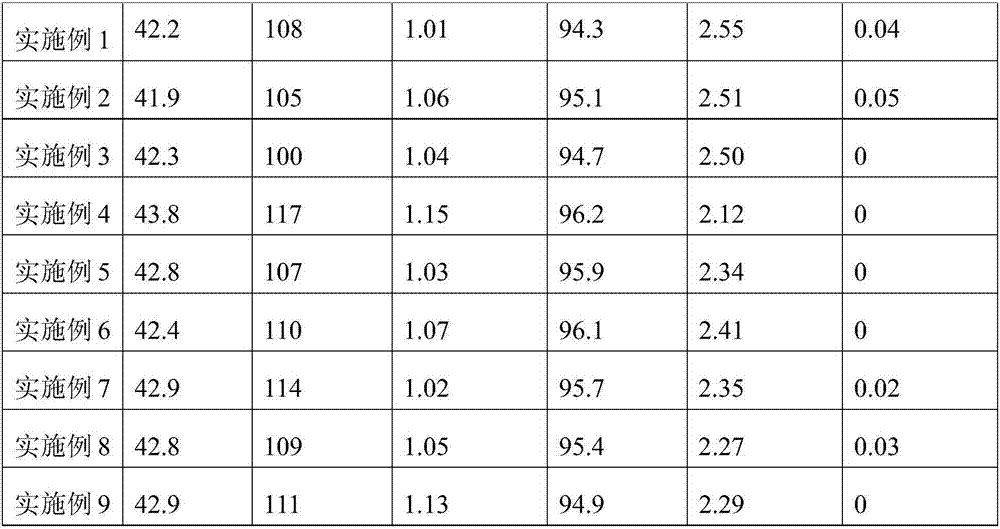

Examples

Embodiment 1

[0033] 1. Preliminary preparation:

[0034] The preparation of chitosan metal complex solution: in parts by weight, after mixing 5 parts of zinc acetate, 1 part of copper acetate, 5 parts of chitosan and 120 parts of acetic acid solution with a mass fraction of 3%, at a temperature of 35 ℃, a stirring speed of 200r / min and an infrared irradiation power of 150W for 30min to obtain a chitosan metal complex solution.

[0035] Preparation of chitosan microspheres: In parts by weight, 20 parts of ferric chloride and 200 parts of deionized water are put into the reactor, rapidly heated to 85° C. under nitrogen protection, and then stirred at 200 r / min Under the condition of 10% mass fraction of sodium hydroxide solution was added dropwise until no precipitation occurred, then 40 parts of chitosan metal complex solution was added, and the reaction was continued for 60 minutes. After microfiltration, the filter residue was washed with ethanol and dried. To obtain chitosan microsphere...

Embodiment 2

[0043] 1. Preliminary preparation:

[0044] The preparation of chitosan metal complex solution: in parts by weight, after mixing 6 parts of zinc acetate, 1.2 parts of copper acetate, 7 parts of chitosan and 120 parts of acetic acid solution with a mass fraction of 3%, at a temperature of 38 ℃, a stirring speed of 250r / min and an infrared irradiation power of 200W for 40min to obtain a chitosan metal complex solution.

[0045] Preparation of chitosan microspheres: in parts by weight, 28 parts of ferric chloride and 245 parts of deionized water are put into the reactor, heated rapidly to 89°C under nitrogen protection, and then heated at a stirring speed of 300r / min Under the condition that the mass fraction is 13% sodium hydroxide solution is added dropwise until no precipitation occurs, then 45 parts of chitosan metal complex solution is added, and the reaction is continued for 70 minutes. After microfiltration, the filter residue is washed with ethanol and dried. To obtain c...

Embodiment 3

[0053] 1. Preliminary preparation:

[0054] The preparation of chitosan metal complex solution: in parts by weight, after mixing 8 parts of zinc acetate, 1.3 parts of copper acetate, 6 parts of chitosan and 120 parts of acetic acid solution with a mass fraction of 3%, at a temperature of 36 ℃, a stirring speed of 370r / min and an infrared irradiation power of 270W for 50min to obtain a chitosan metal complex solution.

[0055] Preparation of chitosan microspheres: In parts by weight, 26 parts of ferric chloride and 280 parts of deionized water are put into the reactor, heated rapidly to 86°C under nitrogen protection, and then stirred at 360r / min Under the conditions of 15% mass fraction of sodium hydroxide solution was added dropwise until no precipitation occurred, then 53 parts of chitosan metal complex solution was added, and the reaction was continued for 67 minutes. After microfiltration, the filter residue was washed with ethanol and dried. To obtain chitosan microspher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com