Catalyst for catalytically synthesizing methyl formate under normal pressure and gas phase and preparation method thereof

A methyl formate and catalyst technology, which is applied in the field of methyl formate preparation, can solve the problems of severe equipment corrosion, high pressure requirements, and backward technology, and achieve the effects of reducing the average dispersed particle size, mild reaction conditions, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

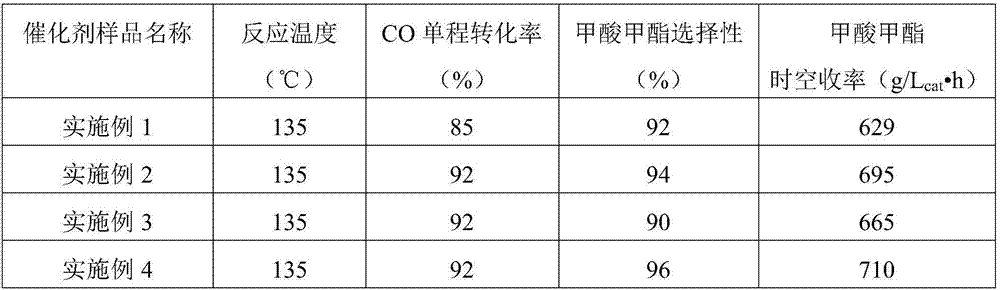

Examples

Embodiment 1

[0018] Dissolve 0.04mol of tetraethyl orthosilicate in 60mL of 6mol / L acetic acid solution, then add 0.04mol of zinc nitrate, 20mL of ethanol, 0.012g of palladium nitrate and 0.06g of PVP in sequence, keep stirring at room temperature for 2 hours, and dissolve them Transfer to a round-bottomed flask and use a rotary evaporator for vacuum distillation. After the solution evaporates, a transparent sol is obtained. Dry the sol in an oven at 100°C for 12 hours, and roast it in a muffle furnace at 450°C for 4 hours. The desired catalyst sample was obtained after reduction under a hydrogen atmosphere at °C for 2 hours, wherein the loading amount of the active component Pd was 0.1% of the weight of the carrier.

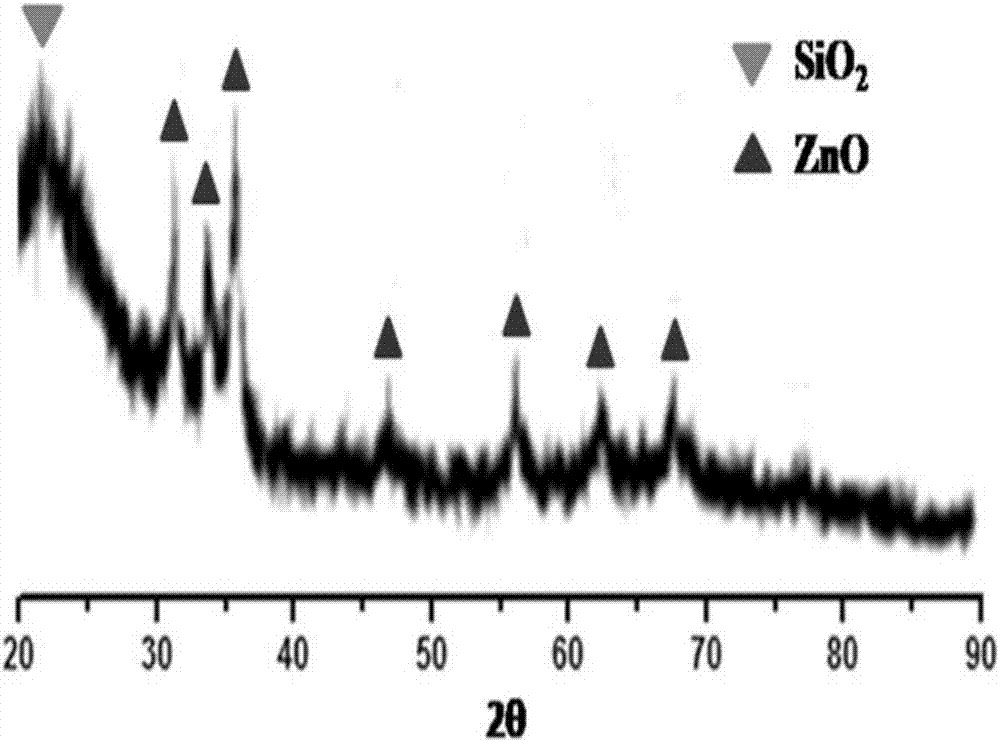

[0019] The phase structure analysis is carried out to the catalyst sample obtained in embodiment 1 by powder diffraction, the results are shown in figure 1 . Depend on figure 1 It can be seen that only SiO appears in the powder diffraction pattern 2 and the diffraction pe...

Embodiment 2

[0021] Dissolve 0.04mol of tetraethyl orthosilicate in 40mL of 6mol / L acetic acid solution, then add 0.06mol of zinc nitrate, 20mL of ethanol, 0.031g of palladium acetate and 0.31g of PVP in sequence, keep stirring at room temperature for 4 hours, and dissolve them Transfer to a round-bottom flask and use a rotary evaporator for vacuum distillation. After the solution evaporates, a transparent sol is obtained. Dry the sol in an oven at 110°C for 12 hours, and roast it in a muffle furnace at 500°C for 2 hours. The required catalyst sample was obtained by reduction under hydrogen atmosphere at °C for 4 hours, wherein the loading amount of the active component Pd was 0.2% of the mass of the carrier. The SiO in the catalyst sample was measured 2 The mass fraction of ZnO is 33.08%, and the mass fraction of ZnO is 57.87%.

Embodiment 3

[0023] Dissolve 0.04mol tetraethyl orthosilicate in 60mL acetic acid solution with a concentration of 6mol / L, then add 0.05mol zinc nitrate, 20mL ethanol, 0.054g tetraammine palladium nitrate and 0.324g PVP in sequence, and keep stirring at room temperature for 6h Then transfer it to a round-bottomed flask and use a rotary evaporator for vacuum distillation. After the solution evaporates, a transparent sol is obtained. Dry the sol in an oven at 80°C for 12 hours, and roast the solid in a muffle furnace at 600°C for 4 hours. The desired catalyst sample was obtained by reducing the substance under a carbon monoxide atmosphere at 200° C. for 2 hours, wherein the loading amount of the active component Pd was 0.3% of the weight of the carrier. The inductive plasma coupling test showed that the SiO in the catalyst sample 2 The mass fraction of ZnO is 37.05%, and the mass fraction of ZnO is 62.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com