Resistance-reducing and antifouling coating composition and resistance-reducing and antifouling coating prepared from same

An antifouling coating and composition technology, applied in the drag reduction and antifouling coating composition and the drag reduction and antifouling coating prepared therefrom, in the field of drag reduction coating, can solve the problem of not forming chemical bonds and coatings. Problems such as the easy migration of toxic and harmful components into the water body, loss of drag reduction and antifouling effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

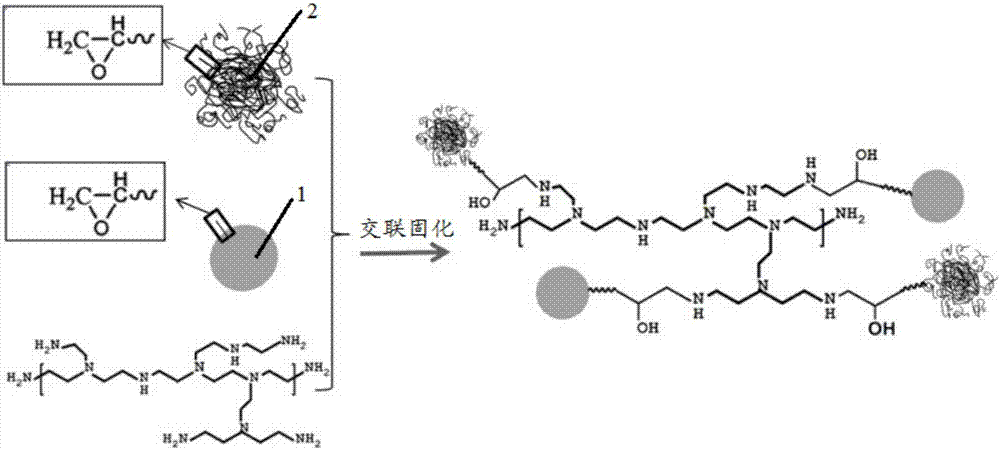

[0039] According to a preferred embodiment of the present invention, the acrylic monomer is shown in formula (I):

[0040]

[0041] Among them, in formula (I), R 1 for C 1 ~C 5 Alkyl or hydrogen, preferably C 1 ~C 3 Alkyl or hydrogen, more preferably methyl or hydrogen; R is C 1 ~C 10 Alkyl group, preferably C 1 ~C 6 Alkyl, more preferably C 1 ~C 4 Alkyl groups such as methyl, ethyl and butyl.

[0042] In a further preferred embodiment, the acrylic monomer is selected from one or more of methyl methacrylate, ethyl acrylate and butyl acrylate.

[0043] Among them, the latex particle 1 obtained by polymerization of acrylic monomers as the main monomer contains both polar ester groups and non-polar alkyl groups, so that the coating has good resistance to polar substrates and non-polar groups. Adhesion makes it suitable for a wide range of substrates, and the cost is low, which is easy to realize large-scale application.

[0044] According to a preferred embodiment ...

Embodiment 1

[0159] The preparation of the first component of embodiment 1

[0160] Add 300g of deionized water into a 500ml reactor equipped with a reflux condenser, pass through nitrogen and exhaust oxygen; add 9.75g of methyl methacrylate, 5.25g of butyl acrylate, and 0.35g of glycidyl methacrylate into the reactor, Raise the temperature to 70°C, stir to heat the material evenly; dissolve 2g of azobisisobutylamidine hydrochloride in 10mL of water, add it to the reactor, stir for 12h, and discharge after cooling to obtain a white polymer emulsion.

Embodiment 2

[0161] The preparation of the first component of embodiment 2

[0162] Add 300g of deionized water into a 500ml reactor equipped with a reflux condenser, pass through nitrogen and exhaust oxygen; add 9.75g of methyl methacrylate, 5.25g of ethyl acrylate, and 0.35g of allyl glycidyl ether into the reactor, Raise the temperature to 60°C, stir to heat the material evenly; dissolve 1.4g of azobisisobutylamidine hydrochloride in 10mL of water, add it to the reactor, stir for 20h, and discharge after cooling to obtain a white polymer emulsion .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com