Preparation method and applications of 3D printing composite magnetic metal scaffold

A composite magnetic and 3D printing technology, applied in the field of biomedical materials, can solve the problems of lack of biological activity, single component, lack of cell recognition sites, etc., achieve good hydrophilicity and biocompatibility, and the preparation method is simple and easy Effects on manipulation, adhesion promotion and proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

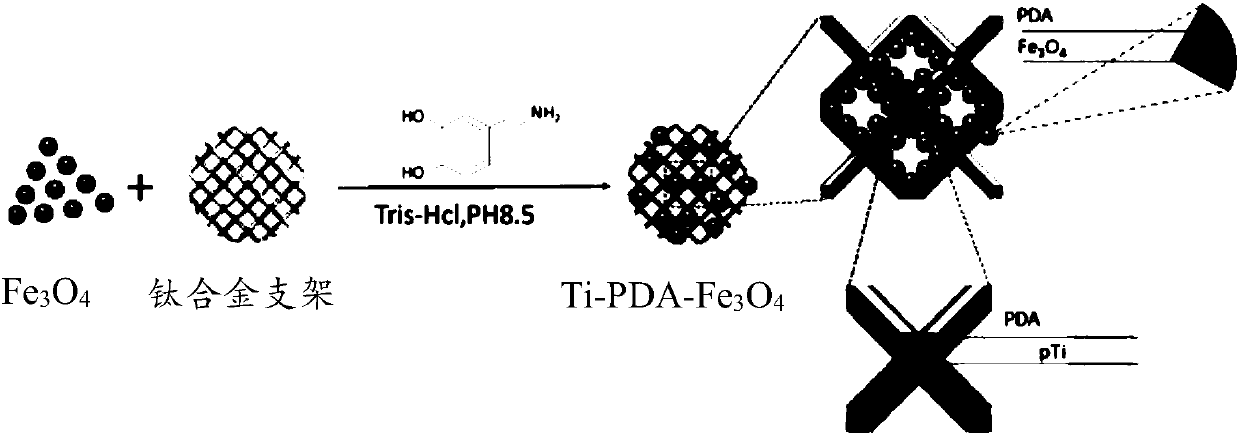

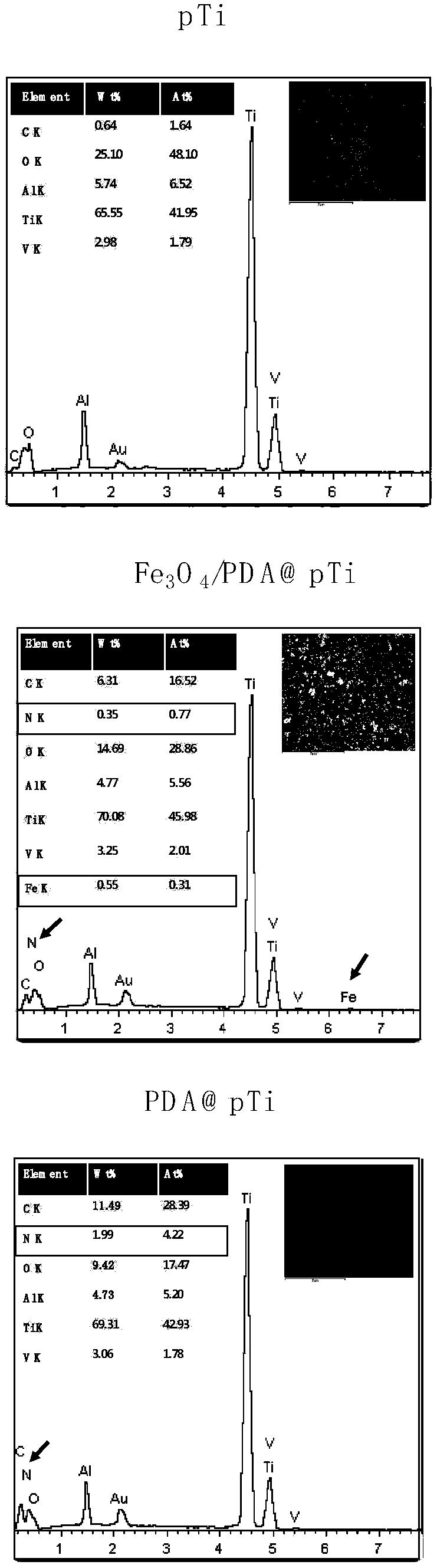

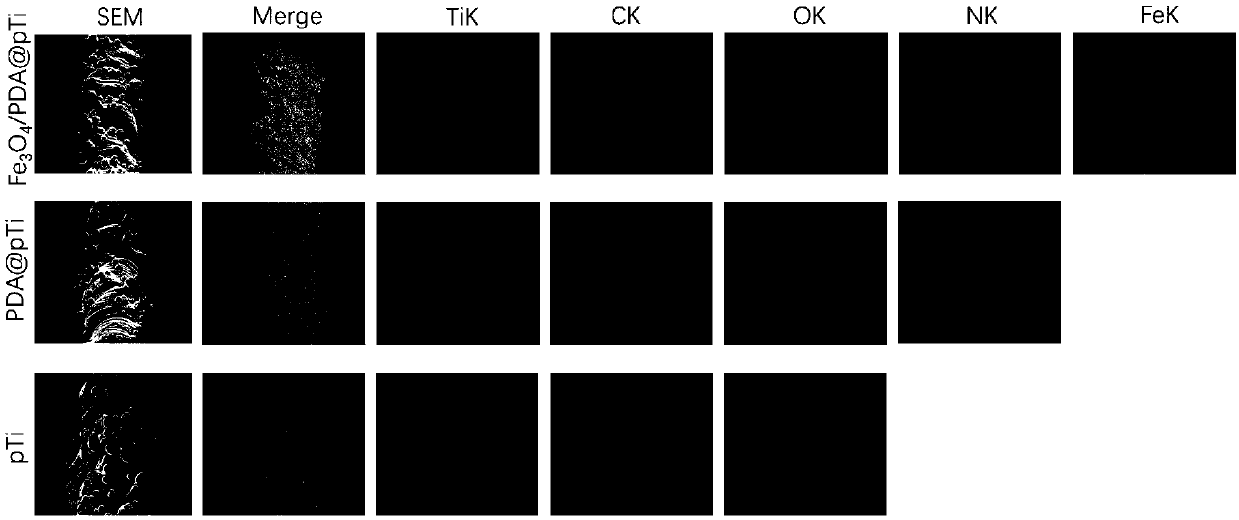

[0035] Example 1 Fe 3 o 4 @PDA Composite Magnetic Titanium Alloy Stent (Ti-PDA-Fe 3 o 4 ) preparation

[0036] 1. Use CAD software to construct a 3D digital model with a dodecahedron as the basic unit, a pore diameter of 300 μm, and a pore column of 200 μm.

[0037] 2. Input the above preparation parameters into the laser 3D printing equipment (ConceptLaser Germany), the maximum scanning speed is 7m / s, and the construction speed is 1-5cm 3 / h. Set the printing layer thickness, melting speed, scanning direction, laser spot interval, powder spreading speed, melt the powder, build up layers, and then use wire cutting to separate samples and heat treatment to release stress.

[0038] 3. Soak in 10% dilute hydrochloric acid overnight, and ultrasonically clean to remove residual titanium alloy powder to obtain a three-dimensional porous titanium alloy stent.

[0039] 4. Fe 3 o 4 The magnetic nanoparticles and the three-dimensional porous titanium alloy scaffold are immersed ...

Embodiment 2

[0041] Example 2 Fe 3 o 4 @PDA Composite Magnetic Titanium Alloy Stent (Ti-PDA-Fe 3 o 4 ) preparation

[0042] 1. Use CAD software to construct a 3D digital model with a dodecahedron as the basic unit, a pore diameter of 600 μm, and a pore column of 300 μm.

[0043] 2. Input the above preparation parameters into the laser 3D printing equipment (ConceptLaser Germany), the maximum scanning speed of this equipment is 7m / s, and the construction speed is 1-5cm 3 / h. Set the printing layer thickness, melting speed, scanning direction, laser spot interval, powder spreading speed, melt the powder, build up layers, and then use wire cutting to separate samples and heat treatment to release stress.

[0044] 3. Soak in 10% dilute hydrochloric acid overnight, and ultrasonically clean to remove residual titanium alloy powder to obtain a three-dimensional porous titanium alloy stent.

[0045] 4. Fe 3 o 4 The magnetic nanoparticles and the three-dimensional porous titanium alloy scaf...

Embodiment 3

[0047] Example 3 Fe 3 o 4 @PDA Composite Magnetic Titanium Alloy Stent (Ti-PDA-Fe 3 o 4 ) preparation

[0048] 1. Use CAD software to construct a 3D digital model with a dodecahedron as the basic unit, a pore diameter of 800 μm, and a pore column of 300 μm.

[0049] 2. Input the above preparation parameters into the laser 3D printing equipment (ConceptLaser Germany), the maximum scanning speed is 7m / s, and the construction speed is 1-5cm 3 / h. Set the printing layer thickness, melting speed, scanning direction, laser spot interval, powder spreading speed, melt the powder, build up layers, and then use wire cutting to separate samples and heat treatment to release stress.

[0050] 3. Soak in 10% dilute hydrochloric acid overnight, and ultrasonically clean to remove residual titanium alloy powder to obtain a three-dimensional porous titanium alloy stent.

[0051] 4. Fe 3 o 4 The magnetic nanoparticles and the three-dimensional porous titanium alloy scaffold are immersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com