Nanometer carbon-based nitrogen-based non-previous metal composite electrocatalytic material, preparation method thereof employing high-temperature annealing and application

A technology of electrocatalytic materials and non-precious metals, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of harsh environmental requirements, cannot directly apply oxygen reduction electrocatalysis, etc., and achieve interface bonding Good, easy mass production, high current density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

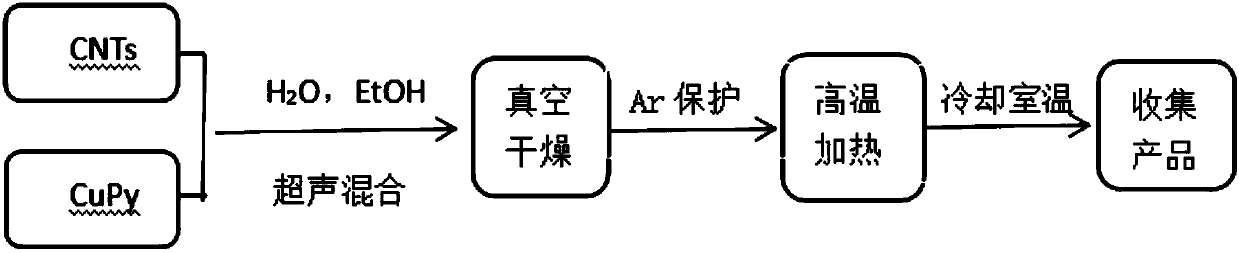

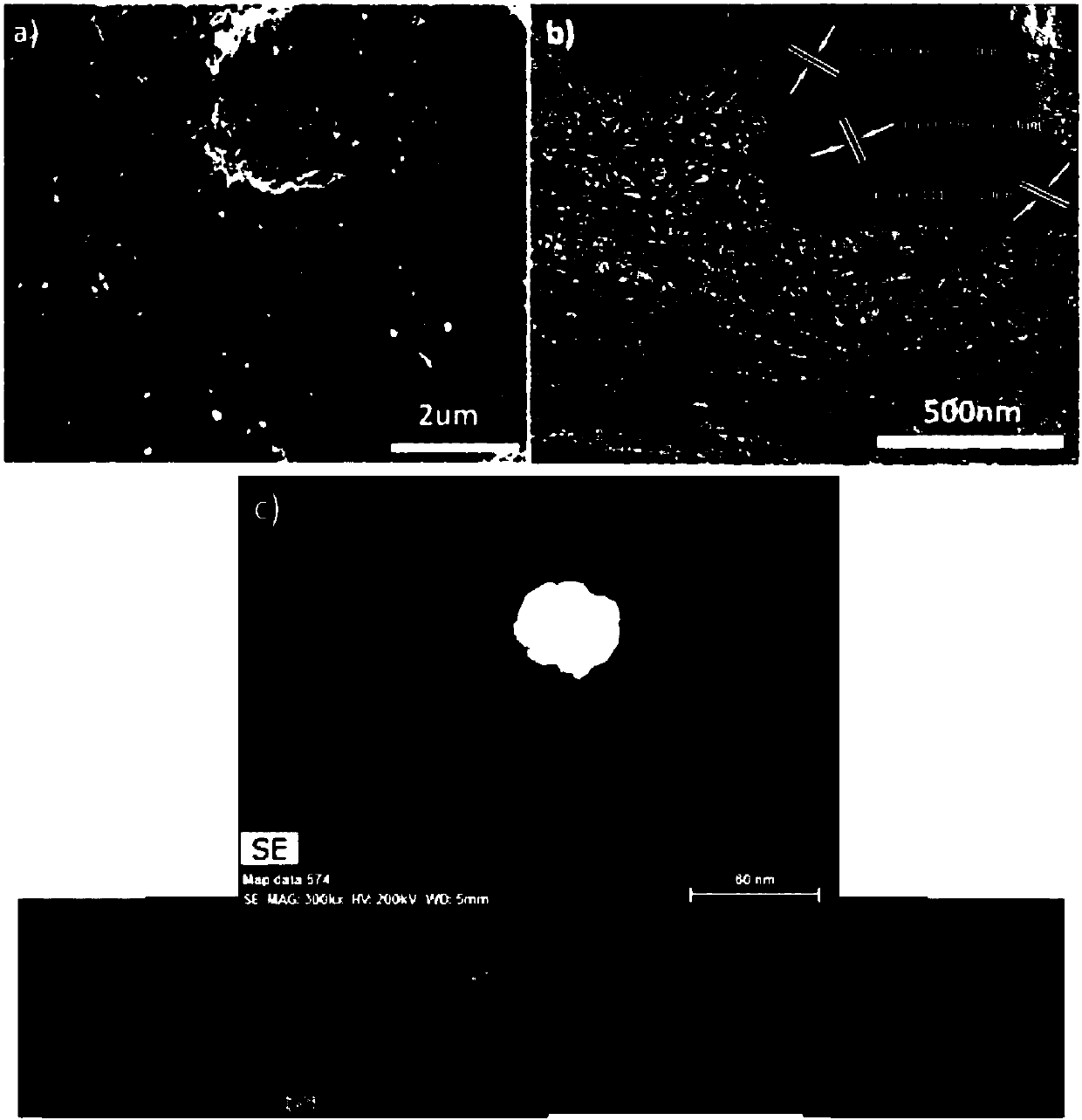

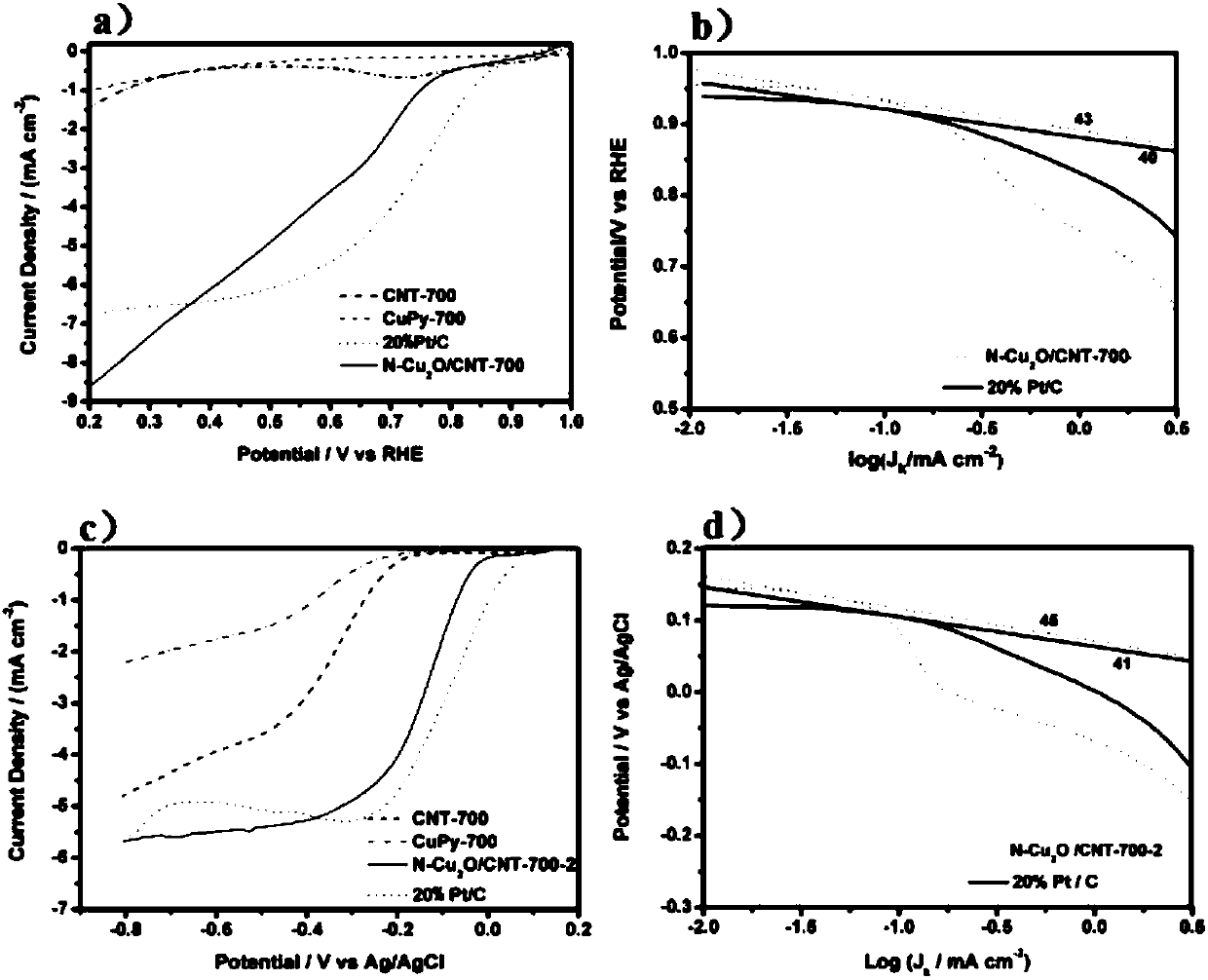

[0031] Preparation of nitrogen-doped cuprous oxide / carbon nanotube composites (N-Cu 2 O / CNTs)

[0032] (1) Raw material pretreatment: Weigh a certain mass of carbon nanotubes and sodium copper chlorophyllin into a 50mL beaker, add a certain amount of a mixture of ethanol and ultrapure water with a volume ratio of 1:1, and place it in a 40KHz ultrasonic wave Ultrasonic in the cleaner, ultrasonic time 2h. Transfer the dispersed suspension to a clean evaporating dish, and quickly dry it in an oven at 150°C for use.

[0033] (2) Preparation of nitrogen-doped cuprous oxide / carbon nanotube composite material: transfer the above materials to a quartz boat; then, place the quartz boat in the quartz tube and place it in a tube furnace for argon protection Gas, except the inner air; set the temperature at 700°C, wait for the temperature to reach the set temperature, keep it for 50 minutes, cool down to room temperature (note: keep the inert gas argon in the whole process), turn off th...

Embodiment 2

[0041] Preparation of cobalt carbide / nitrogen-doped carbon nanotube composites (CoCx / N-CNTs)

[0042] (1) Pretreatment of raw materials Weigh carbon nanotubes and CoPy (cobalt pyridine) with a mass ratio of 1:1 in a 50mL beaker, add a certain amount of ethanol and ultrapure water with a volume ratio of 1:1 , placed in a 40KHz ultrasonic cleaner for ultrasonic dispersion, and the ultrasonic time is 2h. Transfer the dispersed suspension to a clean evaporating dish, and put it into a vacuum drying oven at 150°C for drying for 12 hours.

[0043] (2) Preparation of cobalt carbide / nitrogen-doped carbon nanotube composite material: transfer the dried material in step (1) to a quartz boat; then, place the quartz boat on the quartz tube, and place the quartz tube on the tubular Pass the argon protective gas in the furnace to remove the air inside; set the temperature to 700°C, wait for the temperature to reach the set temperature, keep it for 30 minutes, cool down to room temperature ...

Embodiment 3

[0049] Embodiment 3: prepare germanium oxide / graphene composite material (GeO 2 / Gra)

[0050] (1) Raw material pretreatment: Weigh graphene and carboxyethyl germanium sesquioxide with a mass ratio of 1:1 in a 50mL beaker with an analytical balance, and add a certain amount of ethanol and supernatant with a volume ratio of 1:1. After the mixed solution of pure water is placed in a 40KHz ultrasonic cleaner for ultrasonic dispersion, the ultrasonic time is 2h. Transfer the dispersed suspension to a clean evaporating dish, and quickly dry it in an oven at 150°C for use.

[0051] (2) Preparation of germanium oxide / graphene composite material: transfer the above materials to a quartz boat; Inner air; set the temperature at 1000°C, wait for the temperature to reach the set temperature, keep it for 50 minutes, cool down to room temperature (note: keep the inert gas argon in the whole process), turn off the argon, and collect the product for later use.

[0052] As a control experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com