TiO2 nano-tube doped with cobalt element and preparation method thereof and applications

A technology of element doping and nanotubes, which is applied in the field of photocatalytic materials and solar energy utilization, to achieve the effect of improving photovoltage and filling factor, excellent photoelectric conversion performance, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

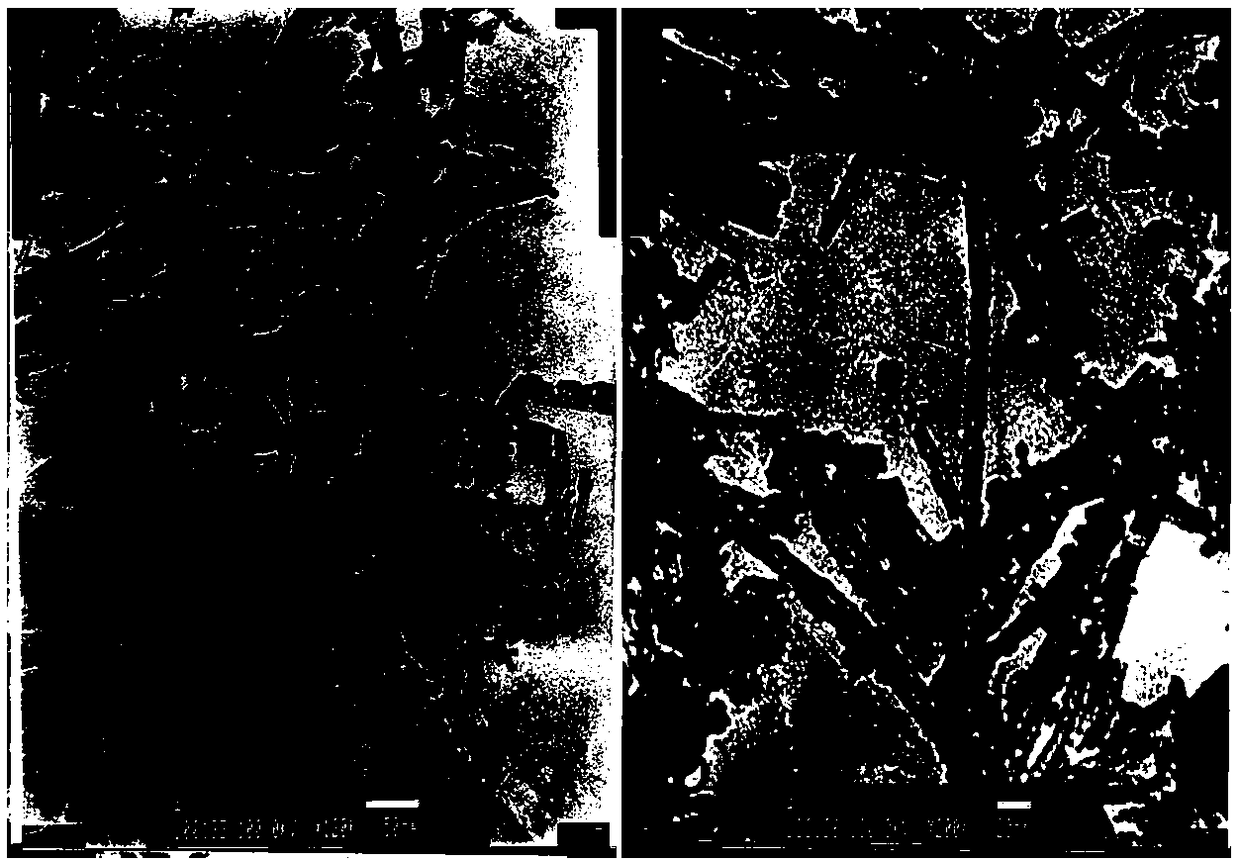

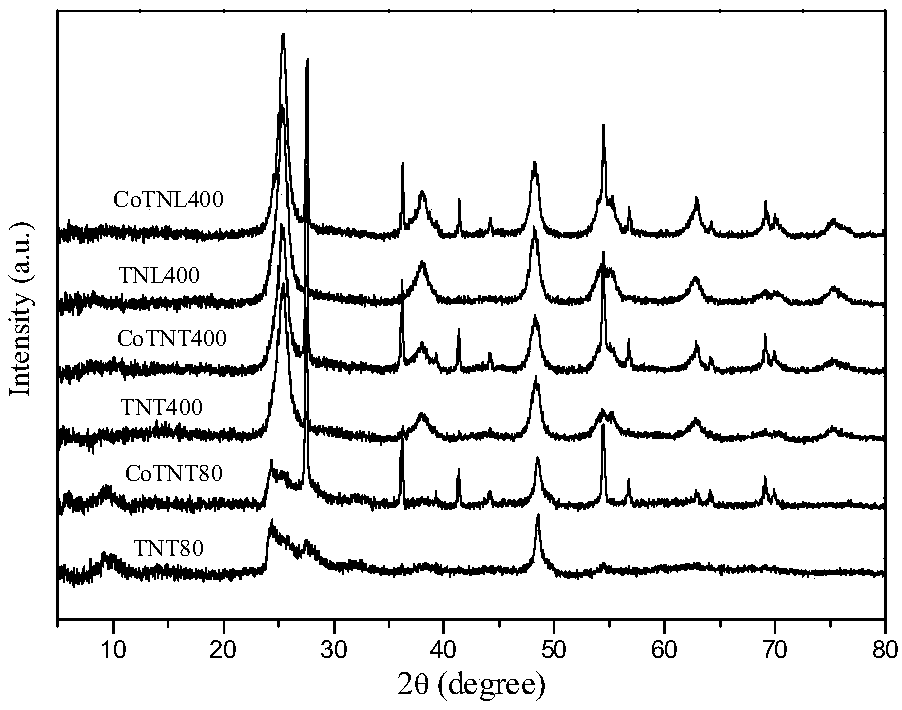

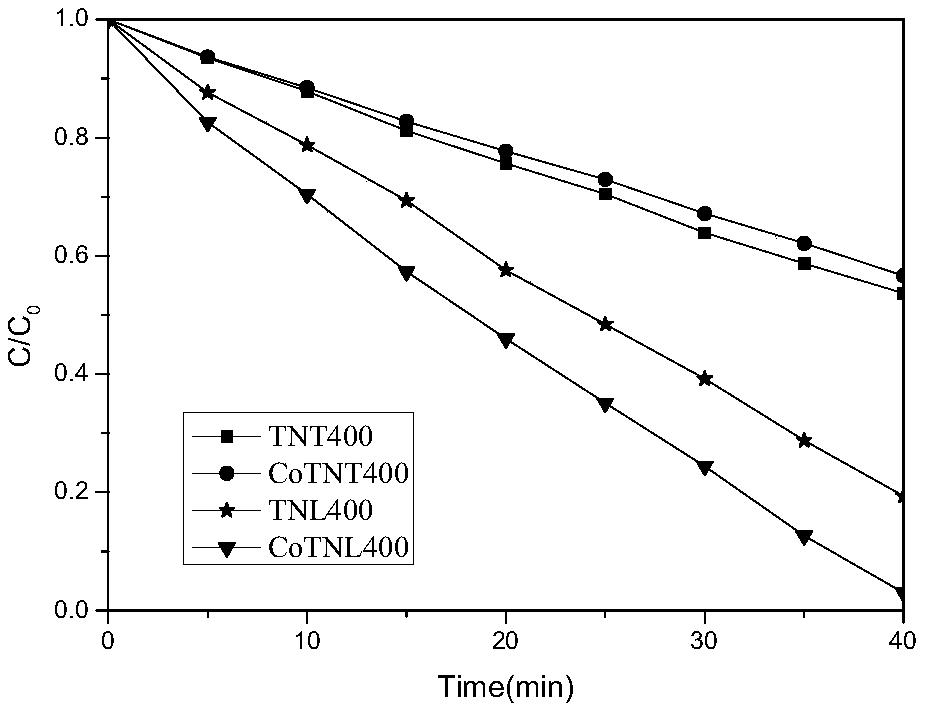

Image

Examples

Embodiment 1

[0030] (1) Preparation of cobalt doped titanium sol

[0031] Put 40mL of deionized water and 5mL of hydrochloric acid in a three-necked flask, and slowly add 50mL of TiCl dropwise under stirring 4 , continue to stir for 1 h after dropping, and stand in the dark for 24 h to obtain a titanium sol; according to the molar ratio of Co / Ti of 1%, 0.05M cobalt nitrate solution is added dropwise to the titanium sol to obtain a cobalt-doped titanium sol .

[0032] (2) Preparation of cobalt doped TiO 2 Nano powder

[0033] In a three-neck flask equipped with 25mL deionized water and 25mL ethanol, under stirring conditions, slowly add the cobalt element-doped titanium sol and ammonia water dropwise, and then continue to drop a small amount of ammonia water after the sol is added dropwise, until the pH 8 to 9, the cobalt-doped titanium gel is obtained; the gel is dried at 100°C and fired at 650°C for 1 hour to obtain cobalt-doped TiO 2 Nano powder.

[0034] (3) Preparation of cobalt-d...

Embodiment 2

[0038] Steps (1) and (2) are the same as in Example 1.

[0039] (3) Preparation of cobalt-doped TiO by hydrothermal synthesis combined with liquid deposition 2 nanotube

[0040] A, the cobalt element that step (1) makes is doped TiO 2 2g of nanopowder and 40mL of 10M NaOH solution were placed in a stainless steel hydrothermal reaction kettle, hydrothermally reacted at 140°C for 48h, cooled to room temperature after the reaction, the white precipitate was taken out, and washed several times with deionized water until the supernatant was neutral , and then soaked in 0.1M HCl solution for 5h, continued to wash several times with deionized water until the supernatant was neutral, dried the white precipitate at 80°C, and labeled the dried sample as CoTNT80.

[0041] B. Weigh 0.2g CoTNT80 and place it in a mixture of 125mL 0.1mol / L ammonium fluotitanate solution and 125mL 0.3mol / L boric acid solution, liquid phase deposition for 80min, dry at 80°C and continue roasting at 400°C fo...

Embodiment 3

[0042] Example 3: Cobalt doped TiO 2 Application of nanotubes in dye-sensitized solar cells

[0043] (1) Preparation of cobalt doped TiO 2 Nanotube slurry: 3g cobalt doped TiO 2 The nanotube sample was placed in a mortar, then 1 mL of 10% acetylacetone in absolute ethanol was added, and ground for 30 min; then 4.5 mL of water, 0.1 mL of Triton X-100 (TritonX-100 for short) and 30% wt ( 0.9g) the mixed solution of polyethylene glycol (molecular weight 20000), grind 30min, obtain cobalt element doped TiO 2 Nanotube slurry;

[0044] (2) Preparation of TiO by powder coating method 2 Nanotube thin film electrode: use scotch tape to stick longitudinally on the drawn two layers of TiO 2 On both sides of the thin film FTO conductive glass, add 2mL cobalt doped TiO 2 Nanotube slurry, roll coating with a glass rod to form a film, the film area is about 0.4×0.4cm 2 ; Then place the film in a muffle furnace, raise the temperature to 500°C at a rate of 2°C / min, keep it warm for one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com