Preparation method of black rice husk dietary fiber tablets containing rich anthocyanin

A technology of dietary fiber sheet and black rice peel, which is applied in food preservation, food drying, food science and other directions, can solve the problems of long production period, residual reagents, and ineffective utilization of dietary fiber, and achieves easy operation and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

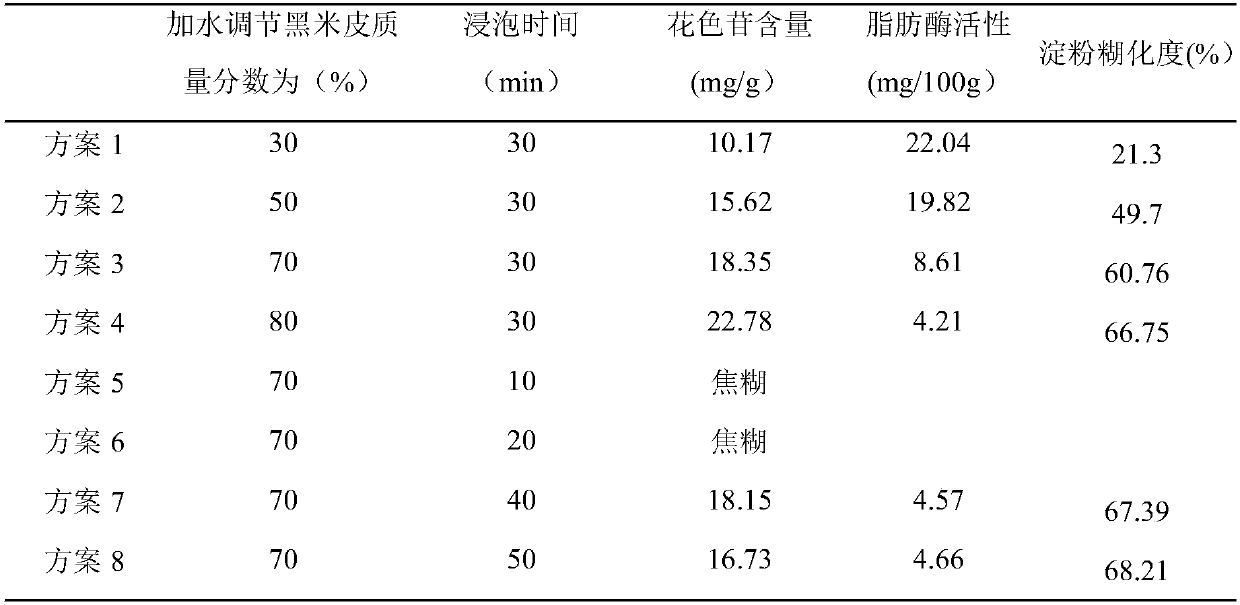

[0043] Example 1 The amount of water added and the impact of soaking time on the black rice husk dietary fiber sheet

[0044] 1000g of black rice was dehulled to obtain 30-mesh black rice husks, and water was added. The wetting time was shown in Table 1. The microwave power was 600W for 7 minutes. The freeze-drying temperature was minus 90-95°C and the freeze-drying time was 72h. , pulverize the black rice bran to 120 mesh, add auxiliary agents microcrystalline cellulose, sodium carboxymethyl cellulose, magnesium stearate, the addition amount is respectively 10%, 3%, 0.4% of the mass fraction of the black rice bran, mix After uniformity, tableting is performed at a pressure of 15Kpa, tableting time is 1min, packaging, ultraviolet sterilization is 2min, and the product is obtained.

[0045] Table 1 The effect of water addition and soaking time on black rice husk dietary fiber sheet

[0046]

[0047] It can be seen from Table 1 that adding less water or soaking for a short t...

Embodiment 2

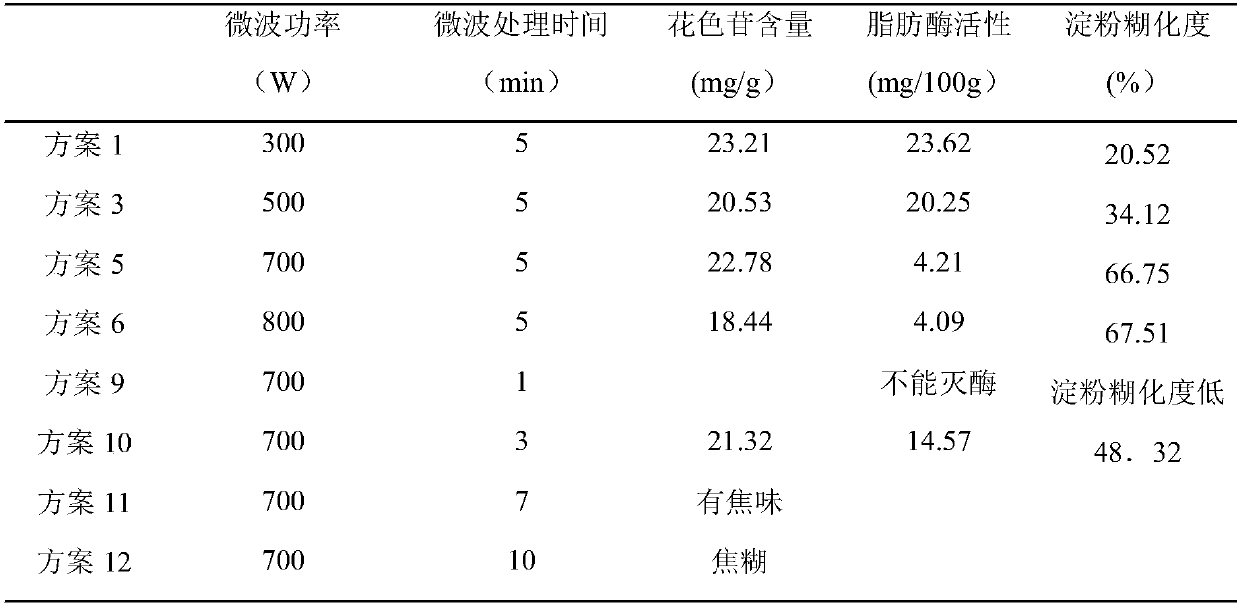

[0048] Embodiment 2 The influence of microwave power and microwave treatment time on black rice husk dietary fiber sheet

[0049] 1000g of black rice was peeled to obtain 30-mesh black rice skin, the mass fraction of black rice skin was adjusted to 80% by adding water, soaked for 30 minutes, microwave power and microwave treatment time were shown in Table 2, and the freeze-drying temperature was 90-95°C. Freeze-drying time 72h. , the black rice bran is pulverized to 100 meshes, adding auxiliary agents microcrystalline cellulose, sodium carboxymethyl cellulose, magnesium stearate, the addition amount is respectively 10%, 3%, 0.4% of the black rice bran mass fraction, carries out Tablet pressing, packaging, ultraviolet sterilization for 1 min, and the obtained product.

[0050] Table 2 Effect of microwave power and microwave treatment time on black rice skin dietary fiber sheet

[0051]

[0052] It can be seen from Table 1 that if the microwave power is too high or the time...

Embodiment 3

[0053] The impact of embodiment 3 auxiliary additive amount on black rice skin dietary fiber sheet

[0054] 1000g of black rice was peeled to obtain 30-mesh black rice skin. Add water to adjust the content of black rice skin to 80%, soak for 30 minutes, microwave power and microwave treatment time are shown in Table 2, and the freeze-drying temperature is minus 90-95°C , freeze-drying time 72h. , crush the black rice husk to 100 mesh, add the type and amount of additives as shown in the scheme below, carry out tabletting, packaging, and ultraviolet sterilization for 1 min to obtain the product.

[0055] Scheme 1: Auxiliaries microcrystalline cellulose, sodium carboxymethyl cellulose, and magnesium stearate are added in an amount of 8%, 3%, and 0.4% of the mass fraction of black rice bran, respectively; the disintegration time limit of the dietary fiber tablet is 12.48 min, friability 0.12%, hardness 8.74kgf.

[0056] Scheme 2: Auxiliaries microcrystalline cellulose, sodium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com