A kind of x-ray detector based on nano-carbon material/silicon heterojunction and its preparation method

A nano-carbon material and silicon heterojunction technology, applied in X-ray detectors and its preparation, X-ray detectors, and X-ray detection fields, can solve problems such as poor X-ray permeability, poor sensitivity, and thick dead layers of devices , to achieve high transmittance, improve response rate, and prevent penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Single-walled carbon nanotubes were prepared by chemical vapor deposition. Through purification and spreading, a thin film with a thickness of 250nm was obtained;

[0042] (2) transferring the single-walled carbon nanotube film to one side surface of the N-type silicon wafer, and drying in a natural state;

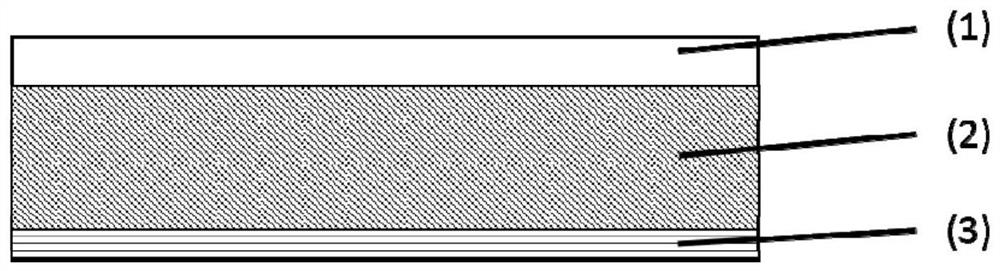

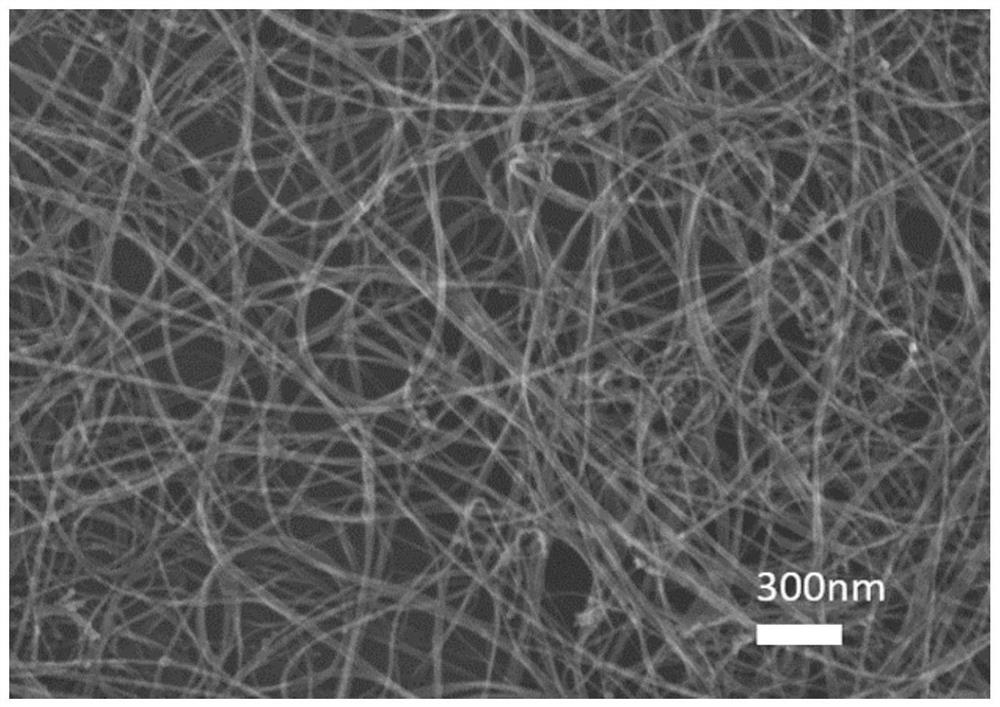

[0043] (3) Ti / Au metal electrode of 50nm is vapor-deposited on the other side of silicon wafer, thereby obtains carbon nanotube / silicon heterojunction X-ray detector, and its structure is as follows figure 1 shown. figure 2 Shown is a scanning electron micrograph of the carbon nanotube film in the detector;

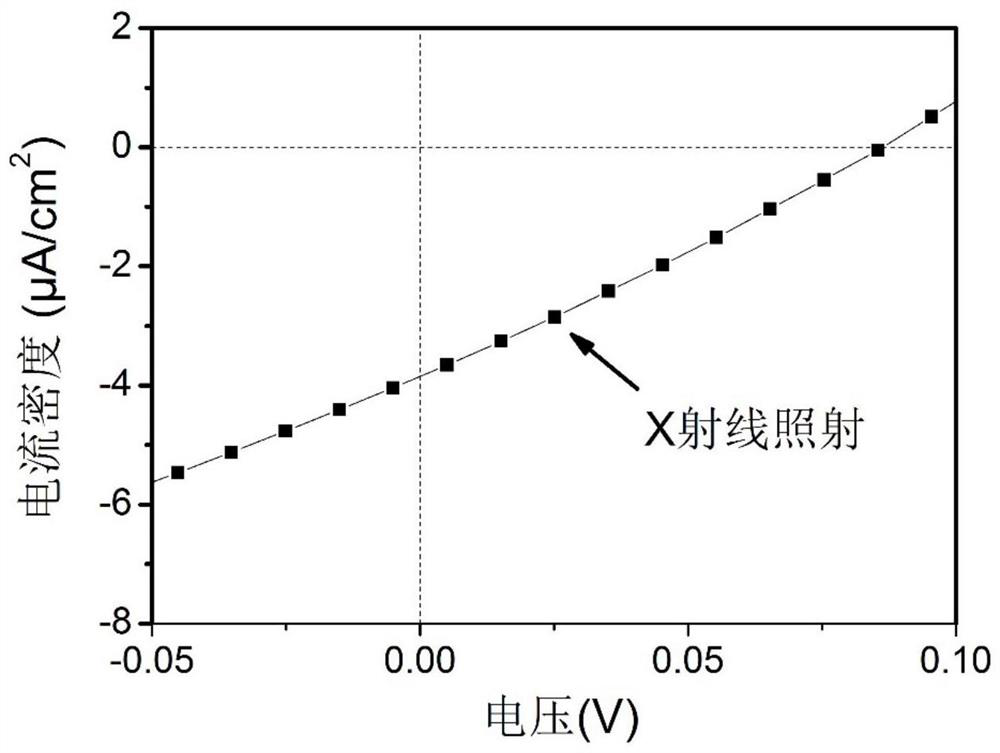

[0044] (4) The detector is at 6.5mGy air Under the irradiation of X-rays / s, the current-voltage characteristic curve of the device is as follows image 3 As shown, its short-circuit current density reaches 3.85μA / cm 2 , while the short-circuit current density of the gold-silicon surface barrier detector as a control sample is only 2.5μA / cm 2 , the res...

Embodiment 2

[0047] (1) Graphene was prepared on nickel foil by chemical vapor deposition. Corroding the nickel substrate with ferric chloride solution to obtain a graphene film with a thickness of 1 μm;

[0048] (2) Transfer the graphene film to one side surface of the N-type silicon chip, and dry it under the irradiation of an infrared oven lamp;

[0049] (3) Coating an indium-gallium alloy on the other side of the silicon wafer as a lower electrode to obtain a graphene / silicon heterojunction X-ray detector. Figure 5 Shown is a scanning electron micrograph of the graphene film in the detector.

[0050] (4) The detector is at 4mGy air / s of X-ray irradiation, the current-voltage characteristic curve of the device is as follows Image 6 As shown, its short-circuit current density reaches 2.16μA / cm 2 , which is higher than the short-circuit current density of the gold-silicon surface barrier detector of the control sample under the same test conditions (only 1.57μA / cm 2 ), the respons...

Embodiment 3

[0052] (1) Multi-walled carbon nanotubes were prepared by chemical vapor deposition. Through purification and spreading, a film with a thickness of 10 μm was obtained;

[0053] (2) The multi-walled carbon nanotube film is transferred to one side surface of the N-type silicon wafer, and blown dry by nitrogen;

[0054] (3) Coating 100nm indium gallium alloy on the other side of the silicon wafer as the bottom electrode, thereby obtaining a carbon nanotube / silicon heterojunction X-ray detector.

[0055] (4) The detector is at 2mGy air / s of X-ray irradiation, the current-voltage characteristic curve of the device shows that its short-circuit current density reaches 1.15μA / cm 2 , while the short-circuit current density of the gold-silicon surface barrier detector as a control sample is only 0.79μA / cm 2 , the response of the device of the present invention is 45.6% higher than that of the control sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com