Method for removing aldehyde impurities in epoxypropane through oxidation method

A technology for propylene oxide and impurities, applied in the field of propylene oxide purification, can solve the problems of frequent regeneration, fast decay of adsorption efficiency, and difficulty in separation by ordinary rectification, so as to reduce product loss and side reactions, simple preparation process, and eliminate content The effect of nitrogen wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of molecular sieve

[0026] (1) TS-1 (Titanium Silicon Molecular Sieve)

[0027] Mix 0.12 parts of tetrapropylammonium hydroxide, 0.065 parts of triethylamine, and 25 parts of water at room temperature according to the molar ratio, add 1 part of ethyl orthosilicate dropwise at 65°C, continue to slowly add dropwise butyl titanate and isopropyl Alcohol, after removing the alcohols from the obtained precursor solution at 80°C, the obtained synthesis solution is transferred into a hydrothermal reactor, crystallized at 180°C for 150h, the obtained product is washed, dried, and calcined at 550°C for 5h to obtain TS- 1.

[0028] (2)Cr-MCM (chromium-containing MCM molecular sieve)

[0029] Mix 1 part of sodium hydroxide, 1 part of cetyltrimethylammonium bromide, 250 parts of water, and 0.1 part of chromium nitrate at room temperature according to the molar ratio, and slowly add 3.5 parts of ethyl orthosilicate to form a molecular sieve synthesis After aging, th...

Embodiment 2

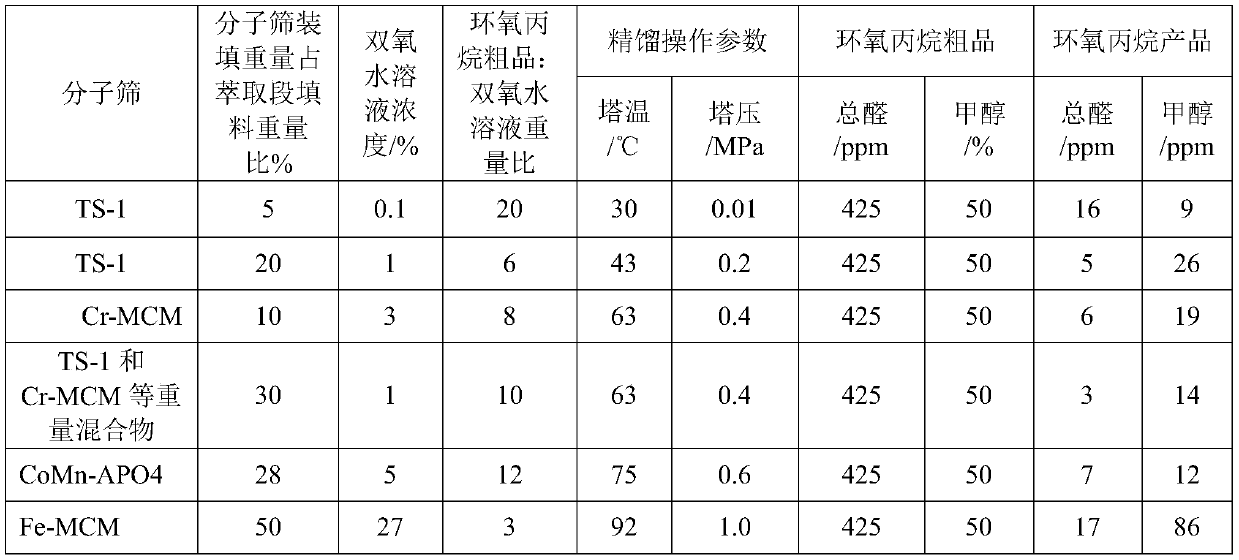

[0034] Example 2: Purification of crude propylene oxide containing aldehydes and methanol impurities

[0035] The middle part of the propylene oxide distillation tower is the extractive distillation section, which is filled with molecular sieves in a certain proportion of the filler weight of the extractive distillation section. The crude propylene oxide is fed from below the extractive distillation section, and the hydrogen peroxide solution is fed above the extractive distillation section. The propylene oxide rectification is carried out at a certain temperature and pressure, the purified propylene oxide product is obtained at the top of the tower, and the aldehyde oxidation product and methanol are discharged from the bottom of the tower.

[0036]

[0037] The content of the present invention is not limited to the content of the embodiments of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com