a co 2 Reductive Bifunctional Photocatalytic Coupled Reaction Method for the Preparation of Renewable Hydrocarbons

A hydrocarbon and coupled reaction technology, applied in the direction of oxidation to prepare carbonyl compounds, carbon compound catalysts, carbon monoxide, etc., can solve the problems of increased economic costs, no improvement in thermodynamics, waste, etc., to improve reaction kinetics and thermodynamics, reduction reaction The effect of high efficiency and promotion of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment prepares Zn according to the following steps 2 In 2 S 5 nanomaterials:

[0021] Step 1, weigh 2mmol zinc sulfate heptahydrate, 2mmol indium chloride hydrate, 10mmol thioacetamide and 0.6g cetyl ammonium bromide respectively in a beaker with 70mL deionized water, stir to dissolve;

[0022] Step 2, transfer the mixed solution in step 1 to a 100ml polytetrafluoroethylene liner, seal it, heat it with water at 160°C, and after 12 hours, wash it with deionized water and dry it in vacuum to obtain Zn 2 In 2 S 5 nanomaterials.

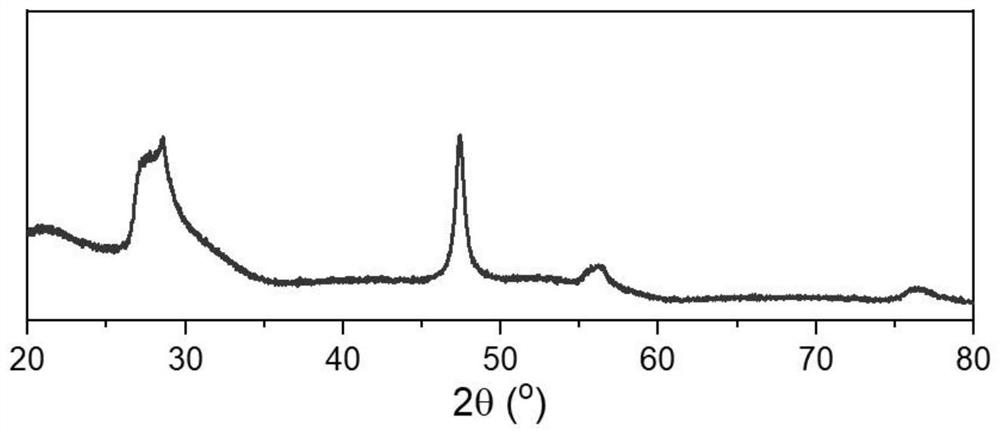

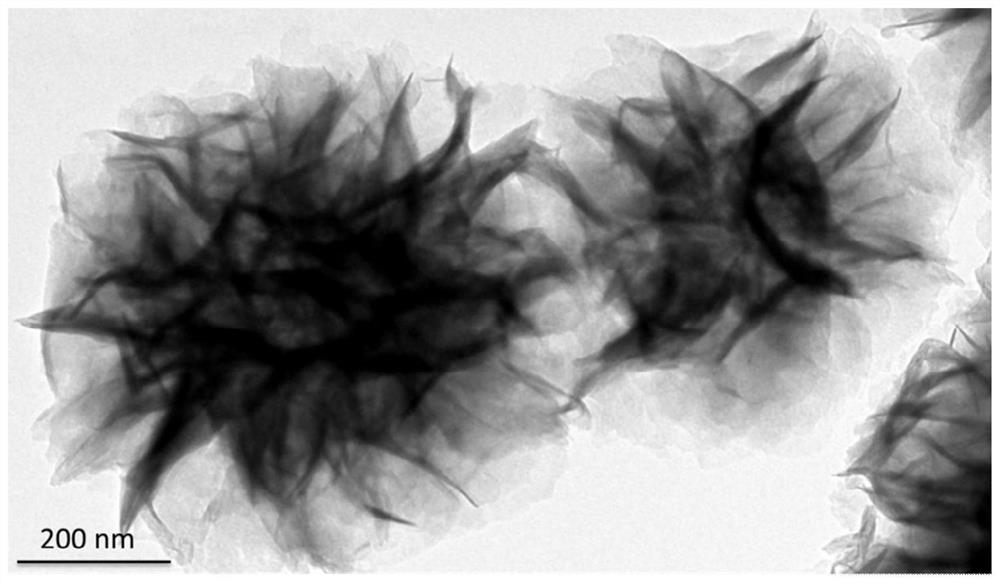

[0023] To the Zn prepared by the embodiment of the present invention 1 2 In 2 S 5 Nanomaterials were characterized, and the results were as follows figure 1 with figure 2 shown. in, figure 1 It is an X-ray diffraction (XRD) pattern, and all the diffraction peaks in the diffraction pattern correspond to the rhombohedral Zn 2 In 2 S 5 . figure 2 It is a transmission electron microscope (TEM) picture, from which it can be ...

Embodiment 2

[0025] This example is a performance test, the detailed steps are as follows:

[0026] Step 1, 0.1g Zn 2 In 2 S 5 Add the powder and 100mL of deionized water into a three-port polytetrafluoroethylene or glass reactor;

[0027] Step 2, one port of the reactor is connected to the vacuum pump, and the other port is connected to CO 2 Gas cylinder, the other branch is connected to the gas chromatograph;

[0028] Step 3, use a vacuum pump to remove the air in the reactor, and introduce CO 2 (40Kpa), stirring makes catalyst and reactant mix uniformly and fully contact;

[0029] Step 4: Turn on the light to obtain a visible light source, irradiate the reaction solution inside the reaction vessel through the glass window of the reaction vessel, and monitor and analyze the gas phase products online every hour. After the reaction, analyze and detect the liquid phase products in the reaction solution.

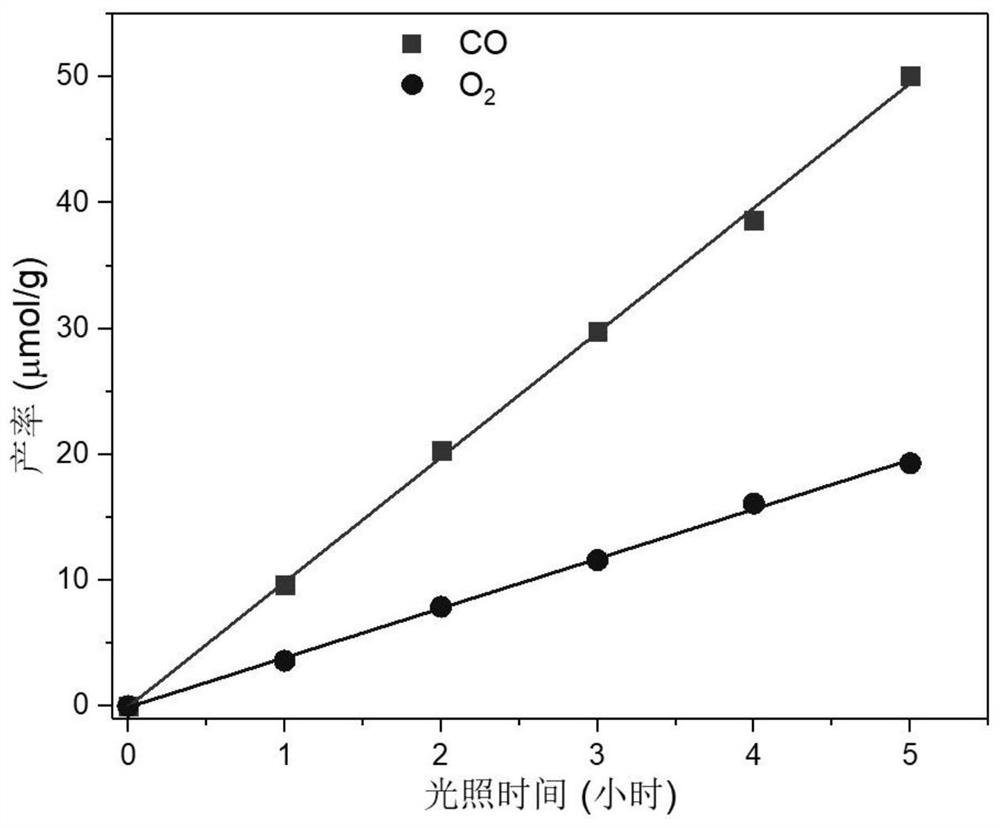

[0030] The result is as image 3 Visible, Zn 2 In 2 S 5 Catalytic reduction ...

Embodiment 3

[0032] This example is the same as Example 2, except that the reaction liquid used in step 1 is 0.3 mol / L, 100 mL aqueous solution of L-lactic acid (L-lactic acid is a hole sacrificial agent).

[0033] The result is as Figure 4 , the addition of sacrificial agent makes Zn 2 In 2 S 5 catalytic reduction of CO 2 The activity has been significantly improved, and the main products are CO and CH 4 , and their formation rates were 6.1 μmol / g / h and 50.3 μmol / g / h, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com