Preparation method for composite polysulfone membrane and application of composite polysulfone membrane in treatment of marine aquaculture wastewater

A polysulfone membrane and a technology for its application are applied in the preparation of composite polysulfone membranes and in the field of marine aquaculture wastewater treatment. Improve the mechanical properties of the membrane, inhibit the growth of microbial bacteria, and improve the effect of pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

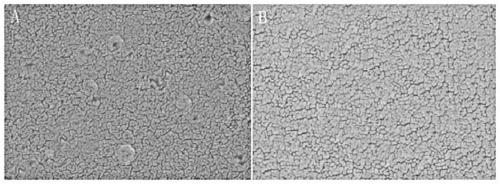

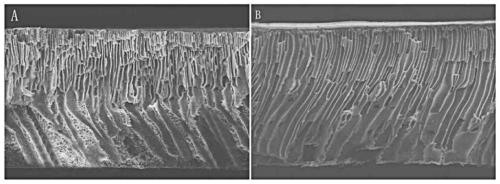

[0033] A method for preparing a composite polysulfone membrane, comprising: providing a base membrane, the base membrane is a polysulfone membrane doped by in-situ polymerization of dopamine, and the base membrane is a semi-interpenetrating network structure; and, cross-linking the shell on the base membrane Copper complexes of polysaccharides were used to obtain composite polysulfone membranes, and the above-mentioned crosslinking occurred in a pulsed electric field environment. The base membrane structure of the composite polysulfone membrane limits the movement of the polysulfone main chain, improves the mechanical properties of the composite membrane, enhances the separation performance, pollution resistance and acid and alkali resistance of the composite membrane, and prolongs the service life of the membrane. The up-crosslinked chitosan copper complex has excellent bactericidal effect and slow-release ability, can kill bacteria in wastewater, has long-term bactericidal ef...

Embodiment 2

[0042] The preparation method of composite polysulfone membrane, its concrete steps are as follows:

[0043] 1) Dissolve polysulfone in dimethyl sulfoxide with a solid-liquid ratio of 1:9 g / mL, add dopamine, ethanolamine and methyl jasmonate, which are 57%, 0.33% and 0.17% of polysulfone weight, at 75 Stir and react at ℃ for 9 hours, then centrifugally defoam to form a homogeneous film-forming solution. After casting on a 50cm×50cm glass plate to form a film, immerse in a coagulation bath of potassium hydroxide double-distilled aqueous solution at 35℃ for 28 hours, and replace it every 10 hours. One bath, then take out the film and wash it with double distilled water until neutral, and dry it at 80°C for 20 hours to obtain the base film;

[0044] 2) Dissolve carboxymethyl chitosan in deionized water, adjust the pH to 6.3, add a copper sulfate solution with a volume concentration of 17.5%, react at 35°C for 3 hours, filter, and wash the resulting precipitate to obtain chitosan ...

Embodiment 3

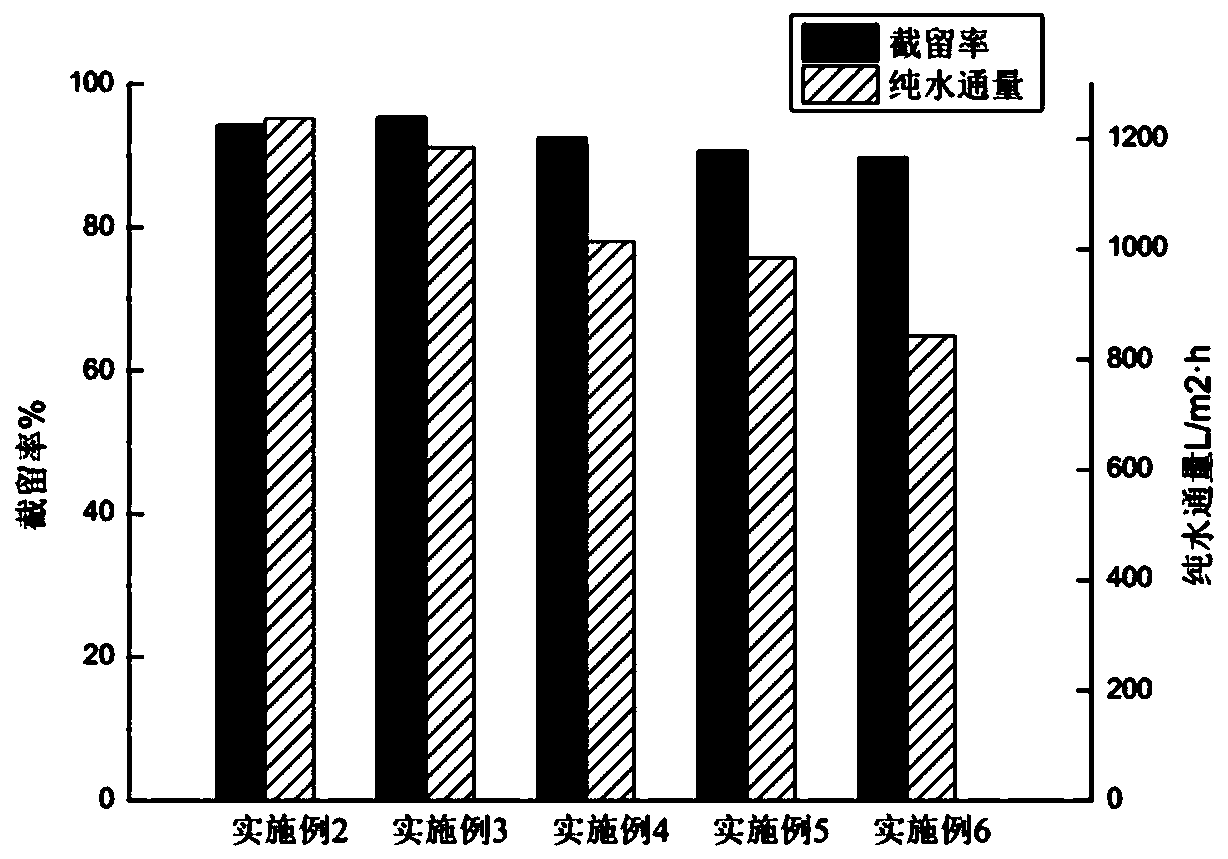

[0048] The difference between this embodiment and embodiment 2 is specifically:

[0049] Step 3) Suspend the chitosan copper complex in 5-8 times the amount of sterilized seawater, and then soak the basement film for preactivation for 30-60min to obtain a cross-linking system. The above-mentioned chitosan copper complex and base The weight ratio of the membrane is 1.15:1. The above-mentioned sterilized seawater contains 0.06mM 6-aminocaproic acid and 0.04mM kresoxim-methyl. The synergistic effect of 6-aminocaproic acid and kresoxim-methyl can be achieved through self-permeation and electric field environment. The systemic effect of the membrane, which gathers inside the membrane pores, can further increase the retention rate of the membrane. At the same time, the membrane pores of the composite membrane are easy to absorb bacteria and macromolecular organic matter in long-term wastewater treatment, resulting in a decrease in the water flow and treatment efficiency of the membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com