A slow-release double-layer oral ulcer film and its preparation method

An oral ulcer, slow-release technology, applied in the field of slow-release double-layer oral ulcer film and its preparation, can solve the problem of increasing the mechanical support and friction of ulcer and oral mucosa, the adhesion time of oral ulcer film needs to be improved, and unfavorable oral cavity Ulcer patient recovery and other problems, to achieve the effect of isolating saliva and external erosion, good bioadhesion, and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

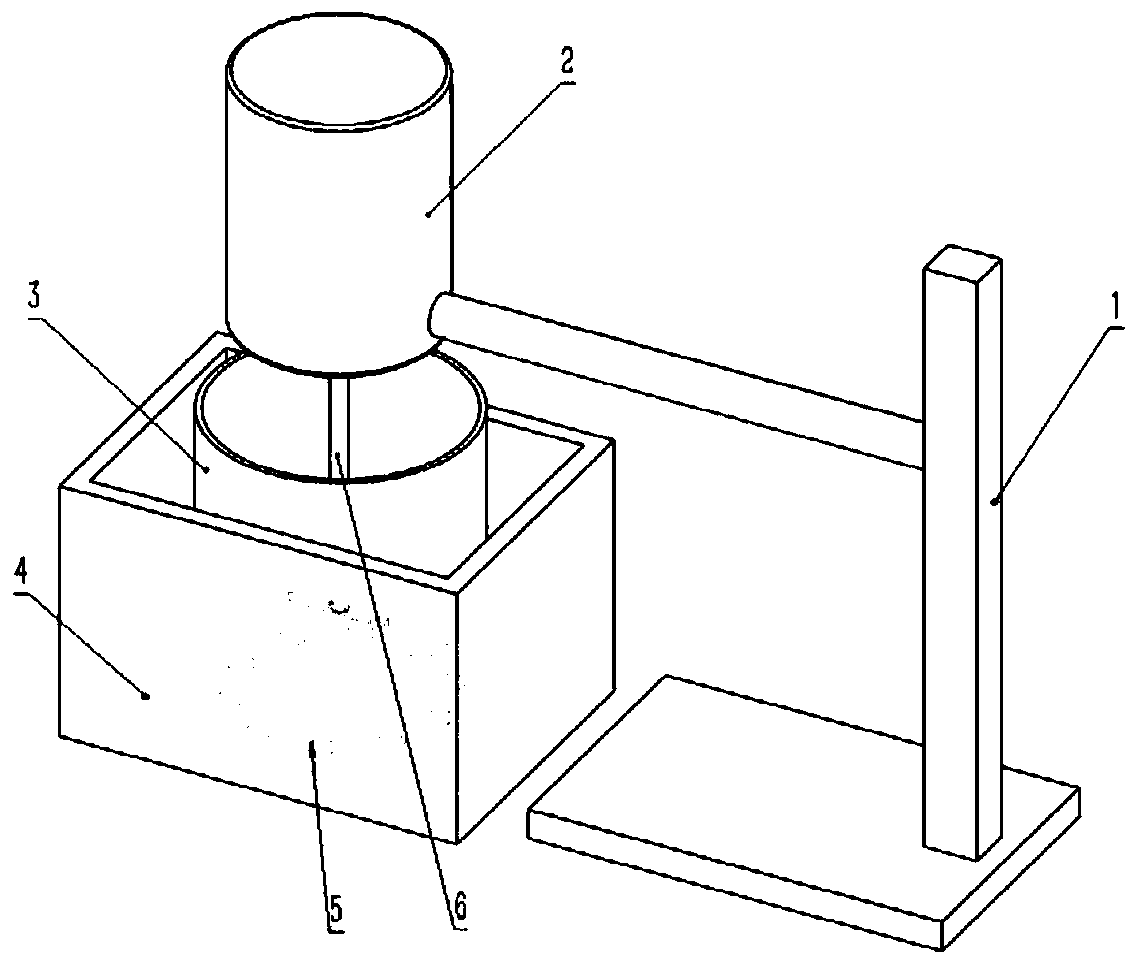

Image

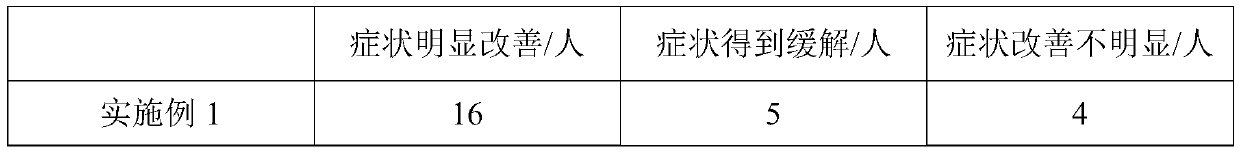

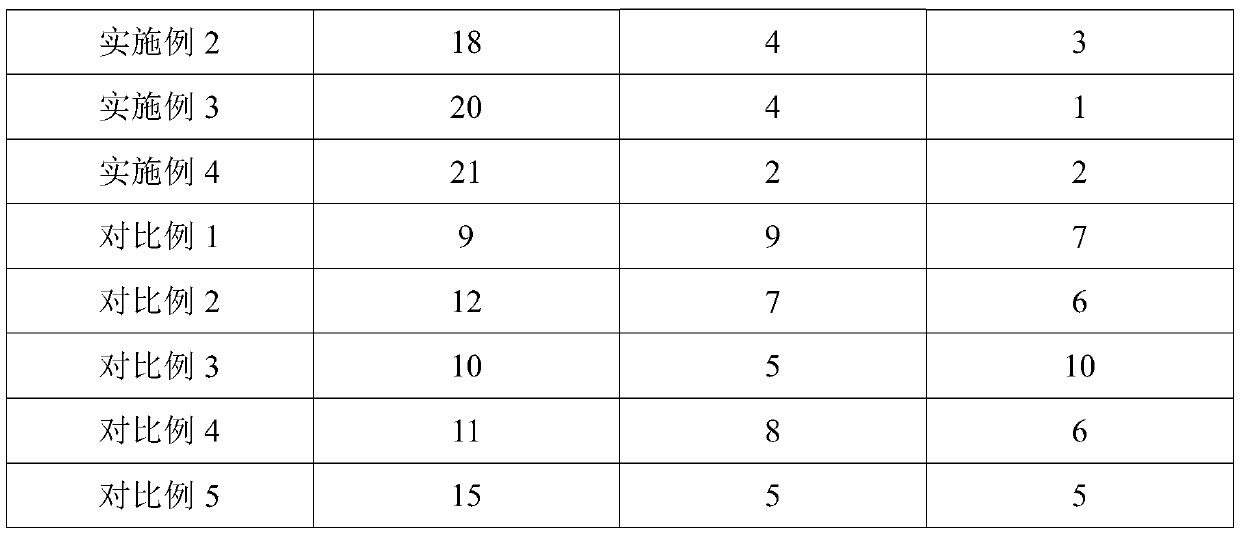

Examples

Embodiment 1

[0063] A slow-release double-layer oral ulcer film, which has a double-layer structure, one layer is a slow-release drug-loaded layer, and the other layer is a waterproof protective layer. The slow-release drug-loaded layer in the finished product is composed of the following components in weight percentage: gelatin 10%, silver nitrate 0.5%, sodium methyl p-hydroxybenzoate 0.1%, stevioside 0.5%, propylene glycol 1%, water balance, and the waterproof protective layer is composed of the following components by weight percentage: corn protein 25%, sesame oil 5% %, the mass fraction is the balance of 80% ethanol.

[0064] The preparation method of oral ulcer membrane comprises the steps:

[0065] (1) Mix 1g of propylene glycol and 89g of water, add 10g of gelatin into the mixed solution of propylene glycol and water, heat and stir at a heating temperature of 70°C, a rotation speed of 30r / min, stirring for 30min, and cool down to 25°C to obtain solution A;

[0066] (2) Add 0.5 g o...

Embodiment 2

[0071] A slow-release double-layer oral ulcer film, which has a double-layer structure, one layer is a slow-release drug-loaded layer, and the other layer is a waterproof protective layer. The slow-release drug-loaded layer in the finished product is composed of the following components in weight percentage: Promellose 50%, levamisole hydrochloride 15%, potassium sorbate 0.5%, acesulfame 2%, polysorbate 5% and water balance, waterproof protective layer is made up of the following components by weight percentage: ethyl cellulose Sodium 80%, triethyl citrate 10% and ethyl acetate balance.

[0072] The preparation method of oral ulcer membrane comprises the steps:

[0073] (1) Mix 5g of polysorbate and 45g of water, add 50g of hypromellose into the aqueous solution of polysorbate, heat and stir at a heating temperature of 80°C, a rotating speed of 70r / min, stirring for 60min, and cooling to 50°C to obtain a solution A;

[0074] (2) Add 15 g of levamisole hydrochloride, 0.5 g of...

Embodiment 3

[0079] A slow-release double-layer oral ulcer film, which has a double-layer structure, one layer is a slow-release drug-loaded layer, and the other layer is a waterproof protective layer. The slow-release drug-loaded layer in the finished product is composed of the following components in weight percentage: slow-release drug-loaded layer 30% film-forming material, 7% chlorhexidine gluconate, 0.3% nisin, 1% sodium saccharin, 3% plasticizer I and the rest of water, and the waterproof protective layer is composed of the following components by weight percentage: poly Vitamin ketone 50%, plasticizer Ⅱ 8% and solvent Ⅱ balance.

[0080] Among them, the plasticizer Ⅰ is a mixture of propylene glycol and glycerol, and the mass ratio of the two is 1:1; the plasticizer Ⅱ is a mixture of castor oil and propylene glycol, and the mass ratio of the two is 1:2, and the solvent Ⅱ is the mass fraction It is a mixed solvent of 95% ethanol and ethyl acetate, and the mass ratio of the two is 3:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com