Astaxanthin nanoliposome and preparation method and application thereof

A technology of nano-liposome and astaxanthin, which is applied in application, climate change adaptation, and additional food elements, can solve the problems of low liposome encapsulation efficiency, poor dispersion stability, capture targeting, etc., to reduce The effect of high sensitivity, high stability and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

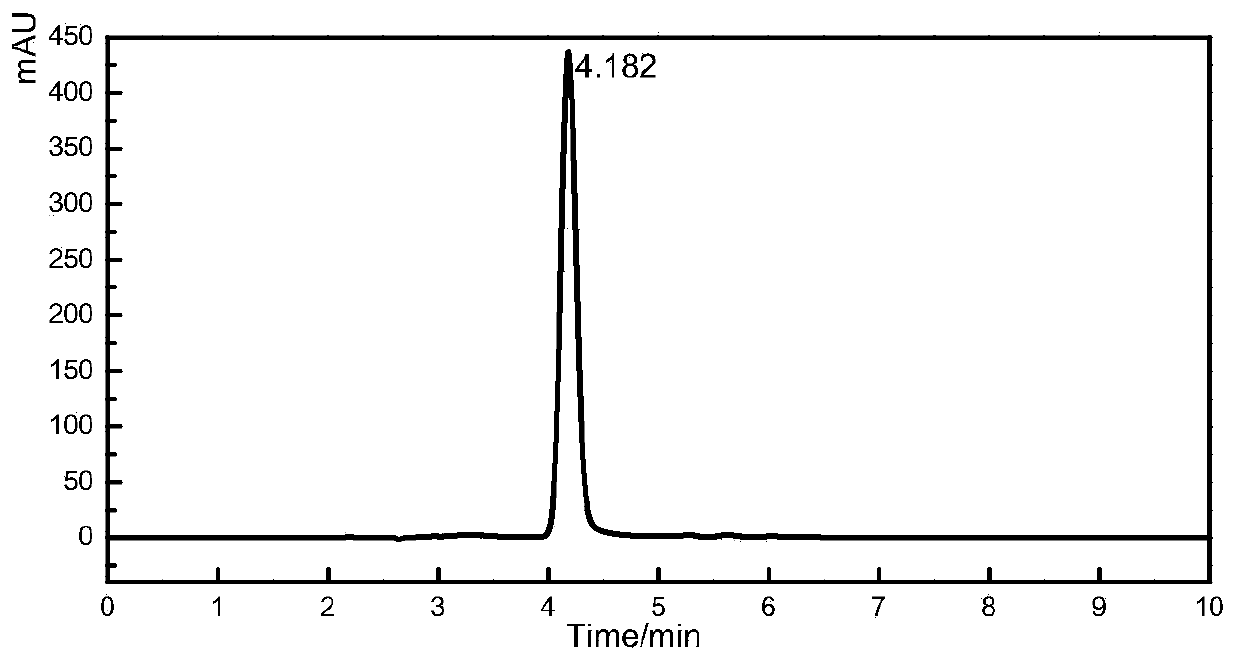

[0047] Embodiment 1 A kind of astaxanthin nano liposome

[0048] 1, the preparation method of astaxanthin nano liposome, comprises the following steps:

[0049] (1) Accurately weigh 1.0 mg of astaxanthin, 210 mg of cholesterol and soybean lecithin (the mass ratio of the two is 1:6); completely dissolve it with a mixed solution of 5 mL of dichloromethane and chloroform at room temperature, and vortex until If there is no insoluble matter, use a rotary evaporator to remove the organic solvent in vacuum at low temperature until a uniform orange-red film is obtained on the wall of the round-bottomed flask of the rotary evaporator, and then place the round-bottomed flask in a vacuum drying oven for vacuum drying for 1 hour;

[0050] (2) Take 20 mL of pre-configured pH=7.5 phosphate buffer solution, slowly pour it into a round bottom flask, and rotate the round bottom flask at an appropriate speed, so that the substances on the inner wall of the flask are evenly dissolved in the buf...

Embodiment 2

[0081] The optimization experiment that embodiment 2 astaxanthin nano liposomes prepares

[0082] (1) Effect of Astaxanthin dosage on liposome encapsulation efficiency

[0083] On the basis of Example 1, the amount of astaxanthin added is 0.5, 1.0, 1.5, 2.0, and 2.5 mg respectively as a single factor variable, and the total amount of cholesterol and soybean lecithin is 210 mg (mass ratio is 1:6), The pH of the buffer solution was 7.5, and other conditions remained unchanged. Astaxanthin nanoliposomes were prepared according to the method of the above-mentioned Example 1, and the effect of the amount of astaxanthin added on the encapsulation efficiency of nanoliposomes was investigated.

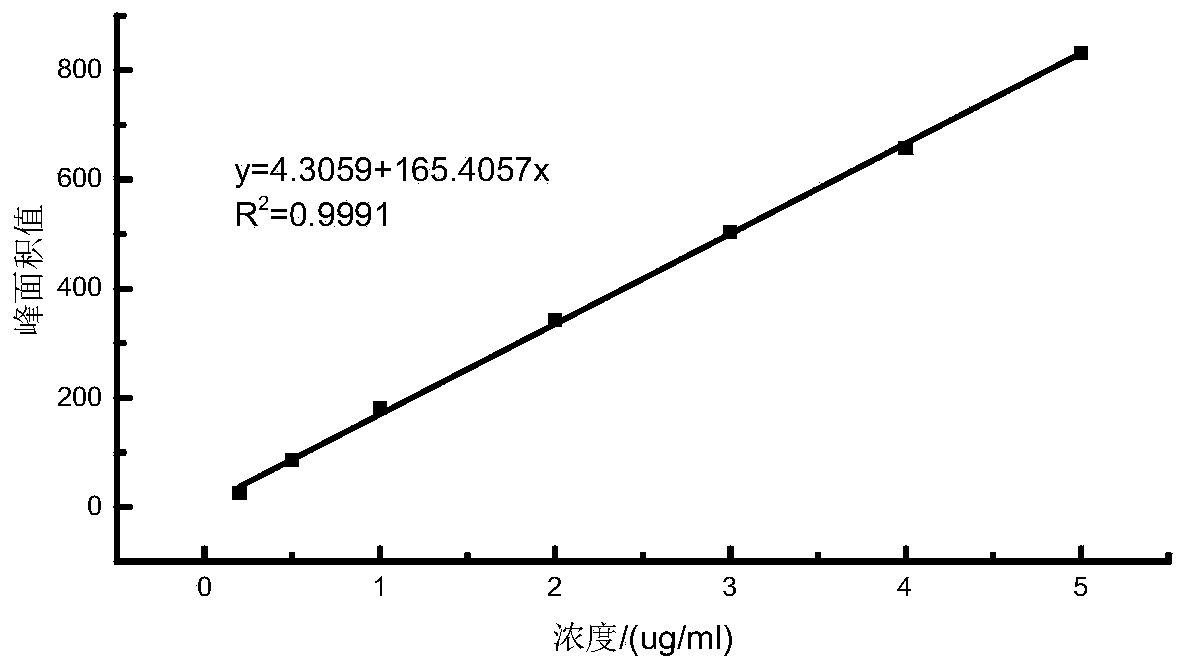

[0084] Depend on Figure 9 It can be seen that when the amount of astaxanthin added is 1.0 mg, the encapsulation efficiency is the highest, reaching 94.12%; but when the amount of astaxanthin added is lower than 1.0 mg, the encapsulation efficiency is low; , the encapsulation efficiency show...

Embodiment 3

[0099] Effect of embodiment 3 astaxanthin nanoliposomes on the growth and immunity of Litopenaeus vannamei

[0100] (1) Test grouping and treatment

[0101] Select juvenile shrimp with normal appearance, strong constitution, and initial body weight of 0.3±0.01g, and randomly distribute them into 12 250L culture tanks, which are blank control group (group B), astaxanthin-added group (AST group), and blank control group (AST group). 4 treatment groups such as liposome group (BL group) and the astaxanthin nano-liposome group (ASTL group) of adding embodiment 1; 43d.

[0102] The prawns in group B were fed with basic feed, and the prawns in group AST, BL and ASTL were fed with basal feed containing astaxanthin, blank liposomes and astaxanthin nano-liposomes respectively; Plastids, astaxanthin and astaxanthin nano-liposomes were added to the basal feed respectively; the amount of astaxanthin added in the AST group and the ASTL group was 80 mg astaxanthin in 1 kg of feed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com