A kind of fiber reinforced composite gel cement material and preparation method thereof

A fiber-reinforced composite and cement material technology, applied in the field of building materials, can solve problems such as economic losses, high maintenance costs, and consumption of maintenance costs, and achieve the effects of improving bending strength and ductility, improving mechanical properties, and increasing mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

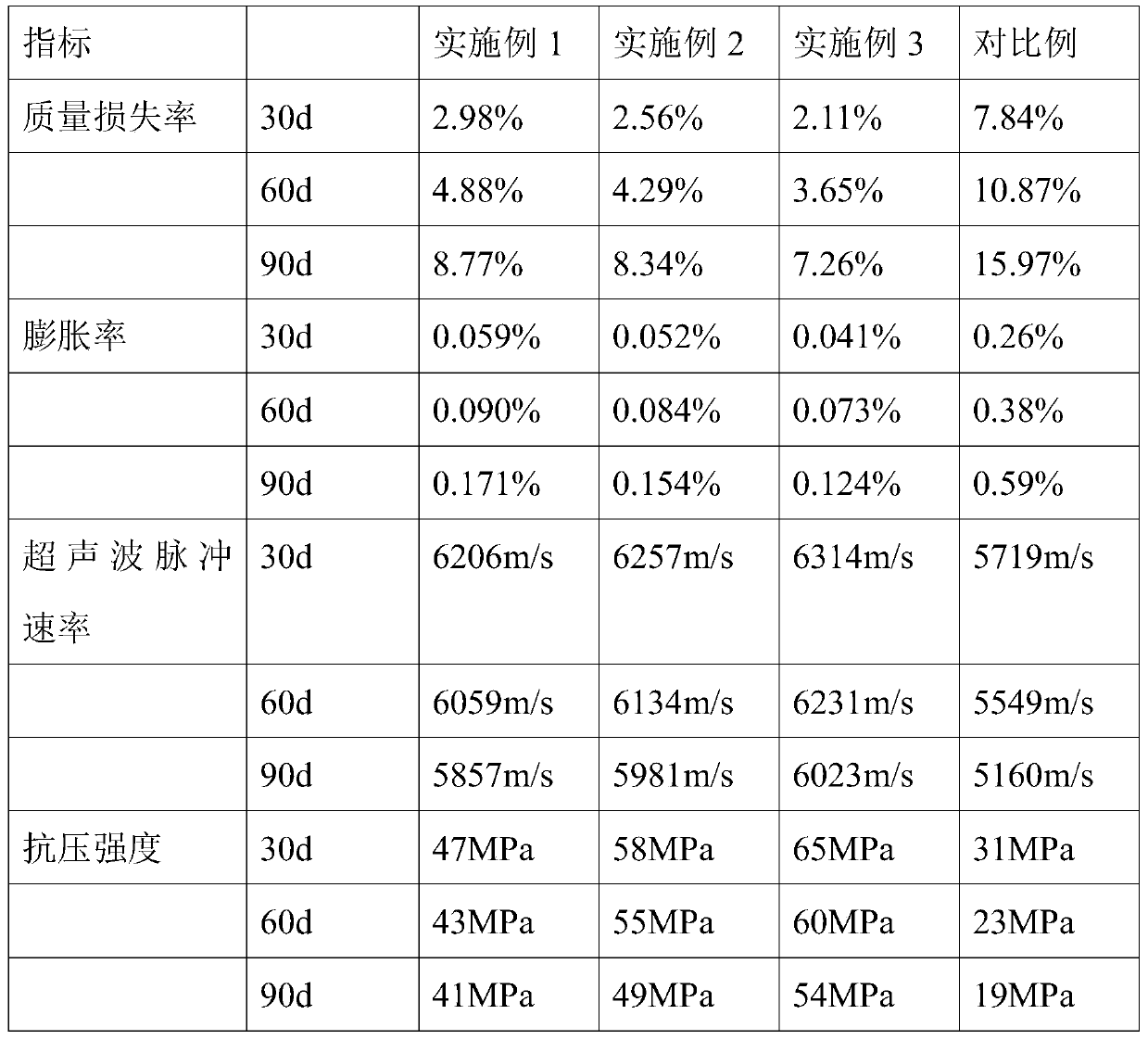

Examples

Embodiment 1

[0042] A fiber-reinforced composite gel cement material provided in this embodiment comprises the following components by weight:

[0043] 30 parts of polyhydroxyethyl methacrylate;

[0044] 30 parts of polyacrylamide-hydrated calcium silicate double network polymer;

[0045] 10 parts of wheat straw, 5 parts of sisal fiber;

[0046] 10 parts of bentonite nanoparticles;

[0047] 10 parts of surfactant;

[0048] 10 parts of graphene;

[0049] 10 parts of tricalcium phosphate;

[0050] 5 parts of potassium persulfate / sodium sulfite redox system initiator;

[0051] 4 parts of sorbitol;

[0052] Polycarboxylate superplasticizer 3 parts.

[0053] Wherein the molar ratio of potassium persulfate to sodium sulfite is 1:5.

[0054] Among them, the polyacrylamide-polyhydrated calcium silicate double network polymer is synthesized by the first network structure of polyhydrated calcium silicate synthesized by the hydration of inorganic substances synthesized from industrial waste a...

Embodiment 2

[0062] A fiber-reinforced composite gel cement material provided in this embodiment comprises the following components by weight:

[0063] 35 parts of polyhydroxyethyl methacrylate;

[0064] 35 parts of polylactic acid-hydrated sulfoaluminate double network polymer;

[0065] 18 parts of corn stalks;

[0066] 15 parts of bentonite nanoparticles;

[0067] 15 parts of surfactant;

[0068] 15 parts of graphene;

[0069] 12 parts of tricalcium phosphate;

[0070] 7 parts of ammonium persulfate / sodium dithionite redox system initiator;

[0071] 6 parts of galactitol;

[0072] Polycarboxylate superplasticizer 4 parts.

[0073] Wherein, the molar ratio of sodium dithionite to ammonium persulfate is 1:2.

[0074] The polylactic acid-polyhydrated sulfoaluminate double network polymer is the first network structure of polyhydrated sulfoaluminate synthesized by the hydration of inorganic substances synthesized from industrial waste and the second polylactic acid synthesized by the...

Embodiment 3

[0082] A fiber-reinforced composite gel cement material provided in this embodiment comprises the following components by weight:

[0083] 40 parts of polyhydroxyethyl methacrylate;

[0084] 40 parts of polyacrylic acid-polyhydrated aluminosilicate double network polymer;

[0085] 10 parts of palm fiber, 10 parts of sugarcane fiber;

[0086] 20 parts of bentonite nanoparticles;

[0087] 20 parts of surfactant;

[0088] 20 parts of graphene;

[0089] 15 parts of tricalcium phosphate;

[0090] 10 parts of potassium persulfate / sodium bisulfite redox system initiator;

[0091] 8 parts of D-mannitol;

[0092] Polycarboxylate superplasticizer 5 parts.

[0093] Wherein, the mol ratio of sodium bisulfite and potassium persulfate is 3:5.

[0094] The polyacrylic acid-polyhydrated aluminosilicate double network polymer is composed of a polyhydrated aluminosilicate first network structure synthesized by hydration of inorganic substances and an organic second network structure syn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com