A preparation method of transition metal chalcogenide layered compound nanosheet material

A technology of layered compounds and transition metals, which is applied in the field of preparation of few-layer nanomaterials, can solve the problems of long preparation period, nanosheet defects, and harsh preparation conditions, and achieve less residual unstripped raw materials and intercalant residues. Less quantity, less cost, green effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

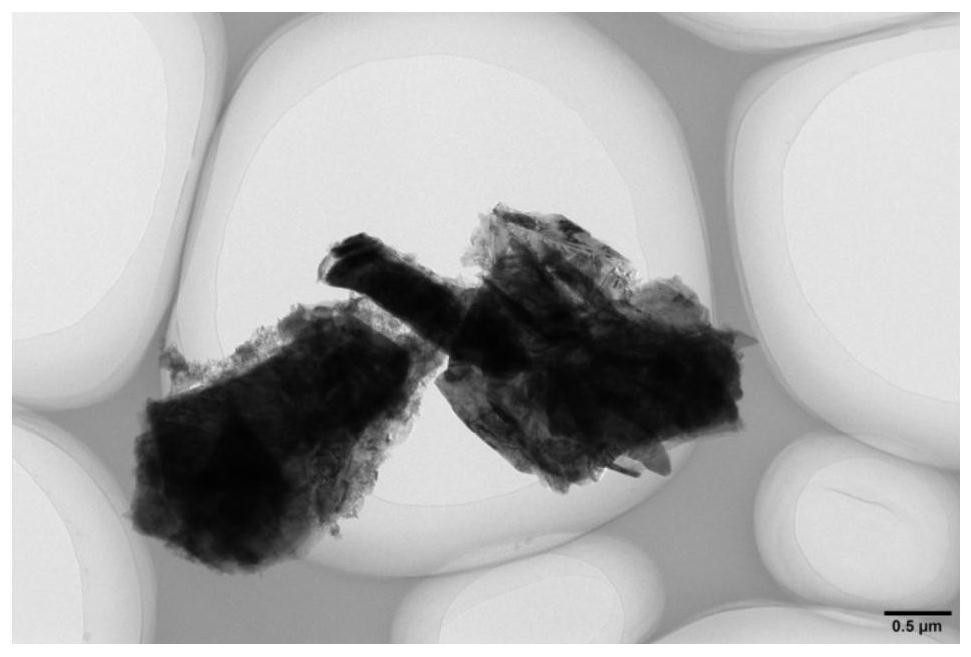

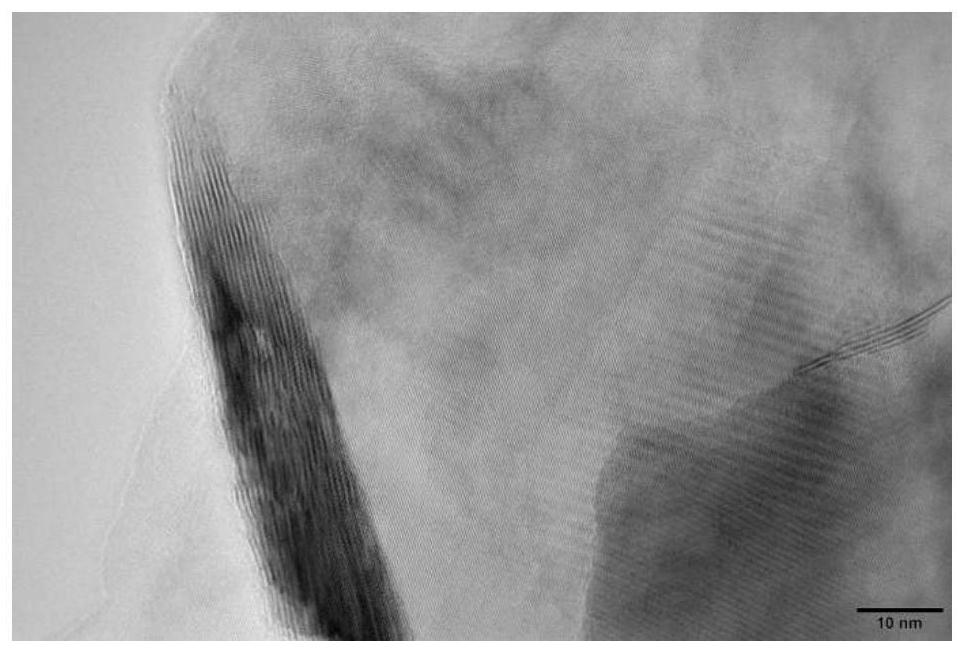

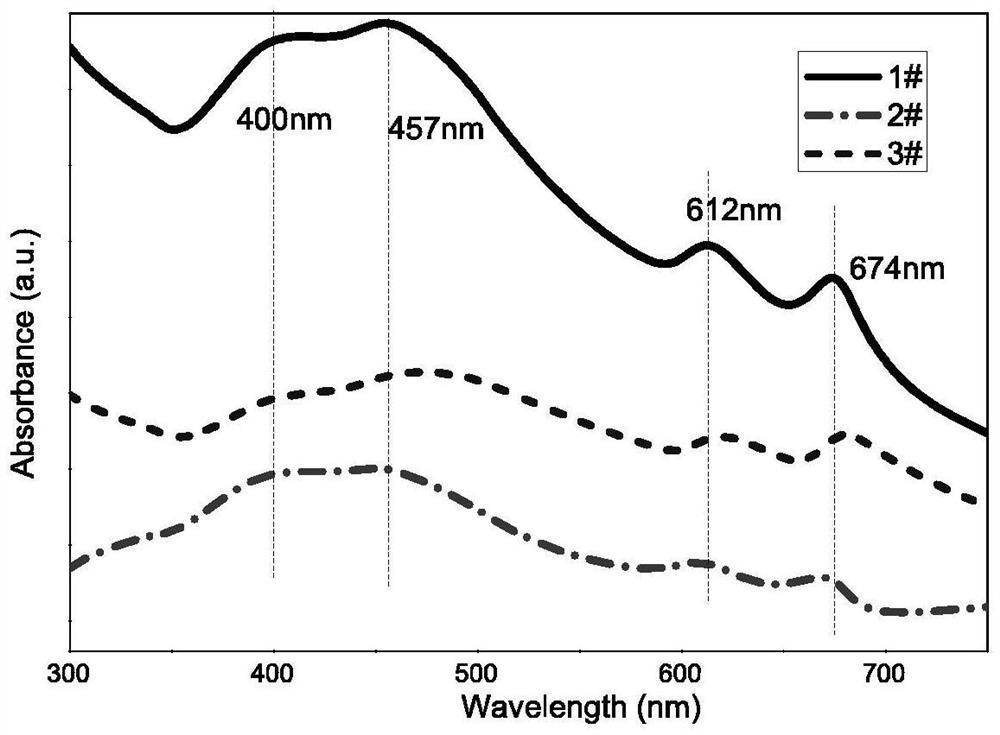

Image

Examples

Embodiment 1

[0036](1) The molybdenum disulfide powder with an average particle size of 10um and polyvinylpyrrolidone (K30) were uniformly mixed in a weight ratio of 98:2 to obtain 30.6g of powder mixture;

[0037] (2) 20 mL of an aqueous electrolyte solution with a concentration of 8 mg / mL was prepared, and the electrolyte was ammonium bicarbonate;

[0038] (3) uniformly dispersing the above-mentioned powder mixture in the above-mentioned aqueous electrolyte solution to obtain a first slurry;

[0039] (4) The above-mentioned first slurry is placed in an electrochemical reaction device for electrochemical intercalation reaction to obtain a second slurry containing the intercalation reaction product, and a square orbit uniform stirring system is introduced during the reaction to always ensure that the first slurry is 1. The slurry is in a state of uniform flow exchange;

[0040] The above-mentioned electrochemical reaction device includes a DC voltage stabilized power supply, a reaction po...

Embodiment 2

[0046] (1) the molybdenum disulfide powder with an average particle size of 20um and polyethylene glycol (relative molecular mass is 1500g / mol) are uniformly mixed in a weight ratio of 99:1 to obtain 30.3g powder mixture;

[0047] (2) 20 mL of an aqueous electrolyte solution with a concentration of 5 mg / mL was prepared, and the electrolyte was hydrogen peroxide;

[0048] (3) uniformly dispersing the above-mentioned powder mixture in the above-mentioned aqueous electrolyte solution to obtain a first slurry;

[0049] (4) The above-mentioned first slurry is placed in an electrochemical reaction device for electrochemical intercalation reaction to obtain a second slurry containing the intercalation reaction product, and a square orbit uniform stirring system is introduced during the reaction to always ensure that the first slurry is 1. The slurry is in a state of uniform flow exchange;

[0050] The above-mentioned electrochemical reaction device includes a DC voltage stabilized p...

Embodiment 3

[0056] (1) the molybdenum disulfide powder with an average particle size of 30um and the dodecyl trimethyl ammonium bromide are uniformly mixed in a weight ratio of 98:2 to obtain a 30.6g powder mixture;

[0057] (2) Prepare 15 mL of an electrolyte aqueous solution with a concentration of 12.5 mg / mL, and the electrolyte is ammonium hydrogen sulfate;

[0058] (3) uniformly dispersing the above-mentioned powder mixture in the above-mentioned aqueous electrolyte solution to obtain a first slurry;

[0059] (4) the above-mentioned first slurry is placed in an electrochemical reaction device to carry out an electrochemical intercalation reaction to obtain a second slurry containing an intercalation reaction product, and a stirring system of uniform circular motion is introduced in the reaction process to ensure that the The first slurry is in a state of uniform flow exchange;

[0060] The above-mentioned electrochemical reaction device comprises a DC voltage stabilized power supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com