Method for purification of D-pinitol from carob bean water extract

A technology for water extract and pinitol, which is applied in the field of D-pinitol purification, can solve the problems of poor purification effect, high sugar content, high impurity content, etc., so as to improve the practical degree and development value, and improve the food safety. , the effect of high conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: D-pinitol purification one

[0041] (1) Raw material pretreatment: Weigh 1kg (about 1000ml) raw material solution carob water extract, then take 0.5L distilled water for dilution, put the diluted raw material solution in the reactor, stir evenly, and then adjust the pH with acetic acid =4-5, stir evenly; in the carob water extract raw material liquid that the present embodiment adopts, contain about 6% of D-pinitol, about 13% of fructose, about 13% of glucose content, about 22.3% of sucrose content, after calculation The raw material liquid contains about 60g of D-pinitol, about 130g of fructose, about 130g of glucose, about 223g of sucrose, and the rest is impurities and water;

[0042] (2) Hydrolysis conversion of sucrose: heat the pretreated raw material liquid water in a water bath until the temperature of the raw material liquid is about 55°C, add 150 mg of invertase, heat-preserve and hydrolyze and stir for 3 hours to obtain a hydrolyzate, and the st...

Embodiment 2

[0047] Embodiment 2: D-pinitol purification two

[0048] Before the purification of D-pinitol, fructose adsorbent needs to be prepared, and the preparation steps are as follows:

[0049] Volcanic stone activation pretreatment: clean 200g of volcanic stone, dry it in an oven at 70°C for 12 hours, then calcinate at 480±5°C for 2 hours, grind it after cooling, and pass through a 100-mesh sieve to obtain activated volcanic stone;

[0050] Volcanic rock removal: add the activated volcanic rock to 15wt% citric acid solution, stir and soak for 10 hours, then clean it with distilled water, then immerse it in 2wt% sodium hydroxide solution, stir and soak it for 8 hours, and then clean it with distilled water. Air-dried; the consumption of citric acid solution and sodium hydroxide solution is to cover the volcanic rock;

[0051] Calcium ions loaded on volcanic stone: Add 10g of ethylenediaminetetraacetic acid into deionized water, stir to dissolve, then add the volcanic stone after rem...

Embodiment 1

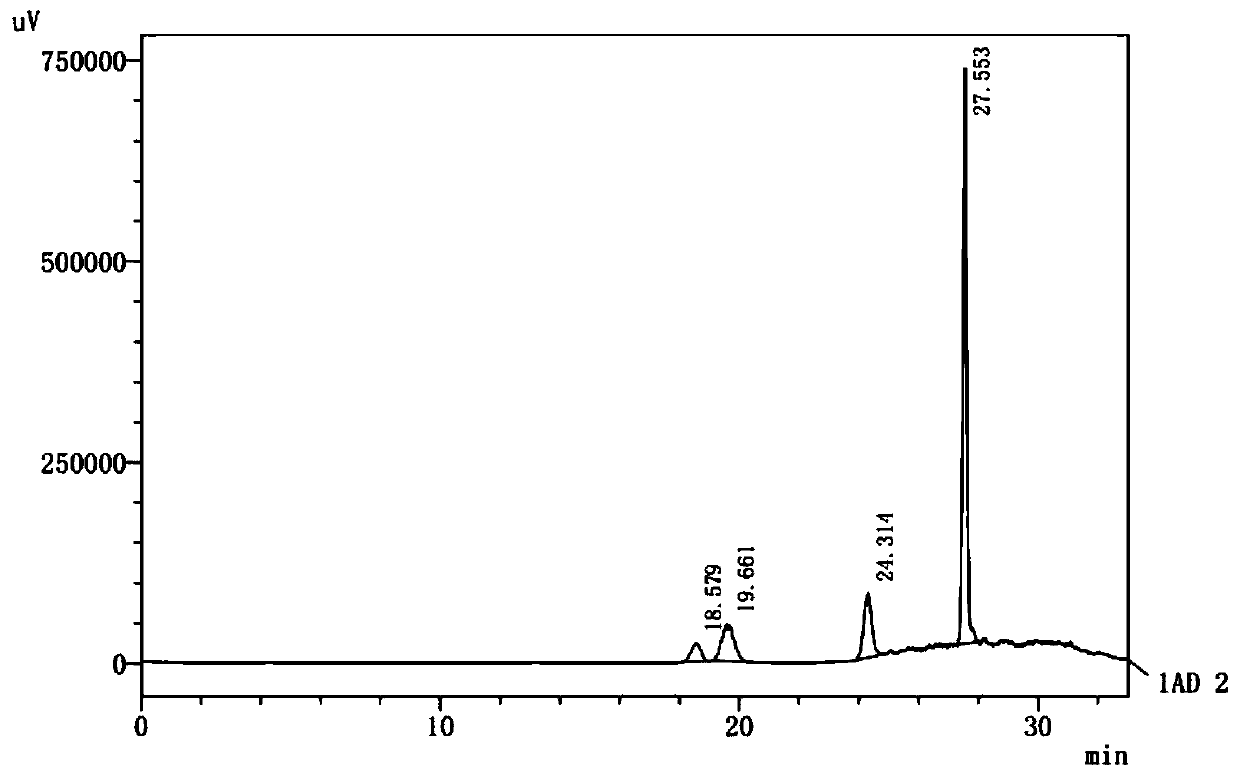

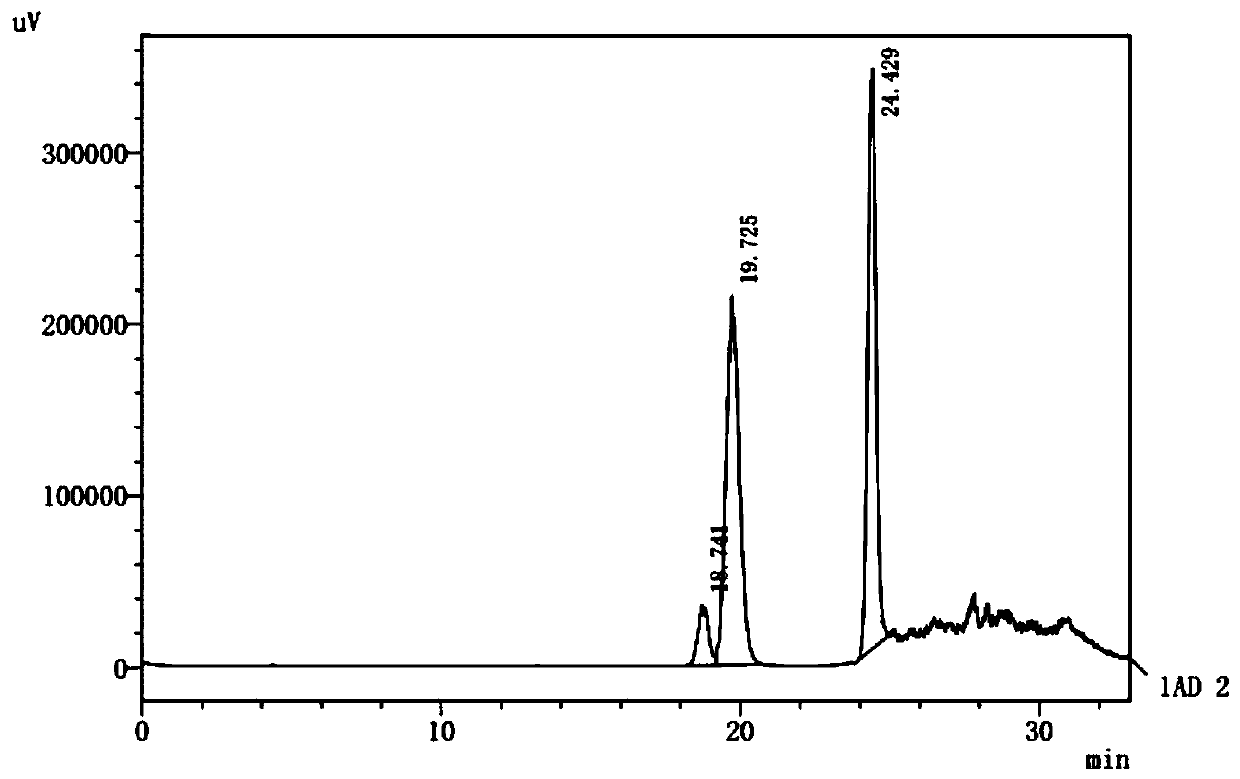

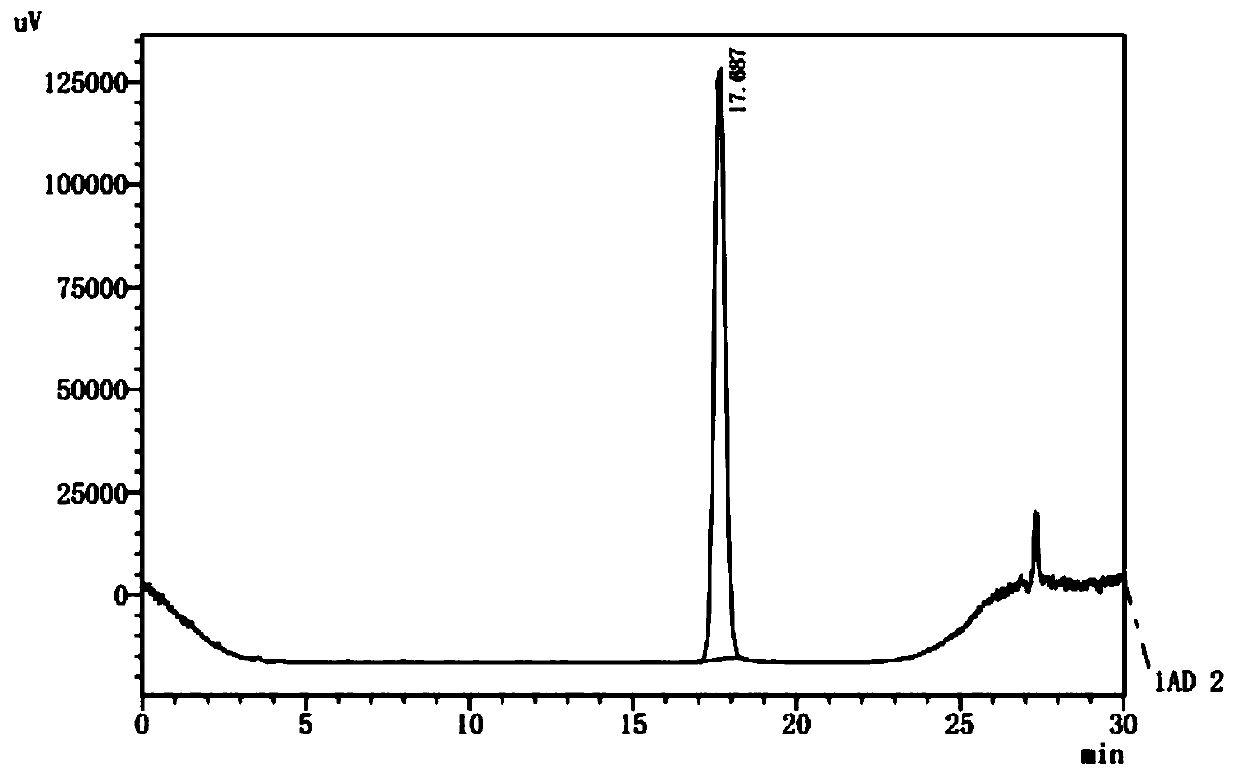

[0060] Detecting Example 1: chromatographic conditions and system suitability test

[0061] Chromatographic column: Agilent sugar analysis column ZORBAX Carbohydrate4.6×250, 5um, flow rate: 1.0ml / min, column temperature: 35°C, water A: acetonitrile B is listed as the mobile phase according to the gradient list, the specific parameters are shown in Table 1; Light scattering detector detection, drift tube temperature: 41°C, air pressure 350-355KPa. The number of theoretical plates should not be less than 2500 based on the peak of bilobalide.

[0062] Table 1

[0063] time, min A,% B,% 0 8 92 20 8 92 25 20 80 40 20 80 42 8 92 45 8 92

[0064] Preparation of control chart: Weigh four reference substances of D-pinitol, fructose, glucose and sucrose respectively, and add water to make a solution with a concentration of 2.0mg / 1ml.

[0065] Preparation of the sample solution: Measure 2.0 g of the corresponding solution in the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com