Magnesium aluminum pentafluoride/nitrogen-doped carbon lithium-sulfur battery positive electrode material and preparation method thereof

A pentafluoro-magnesium-aluminum, positive electrode material technology, applied in battery electrodes, lithium storage batteries, positive electrodes and other directions, can solve the problems of poor conductivity of sulfur and lithium-sulfur products, cumbersome process, low utilization rate, etc., to improve cycle stability, The preparation process is simple and the effect of providing sulfur-carrying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Treatment of attapulgite

[0049] The natural attapulgite was screened with a 200-mesh sieve, and then 6 g of attapulgite was put into 200 mL of hydrochloric acid with a concentration of 4 mol / L, and heated and stirred at 90 ° C for 2 h. Then carry out suction filtration, the product obtained after suction filtration is washed to neutrality, and then the obtained sample is placed in a vacuum drying oven to dry for 12 hours.

[0050] (2) Attapulgite-coated nitrogen-doped carbon

[0051] Weigh the above-mentioned 2g of modified attapulgite, 1.5g of glucose and 0.9g of ammonium chloride into a 100mL beaker, add 40mL of deionized water and continue stirring for 24h, and then put it in a water bath at 80°C until the water is evaporated to obtain the precursor. The above precursor was calcined in a tube furnace under an argon atmosphere at a heating rate of 4°C / min, and calcined at 600°C for 3h to obtain a nitrogen-doped carbon-coated attapulgite composite.

[0052] (3)...

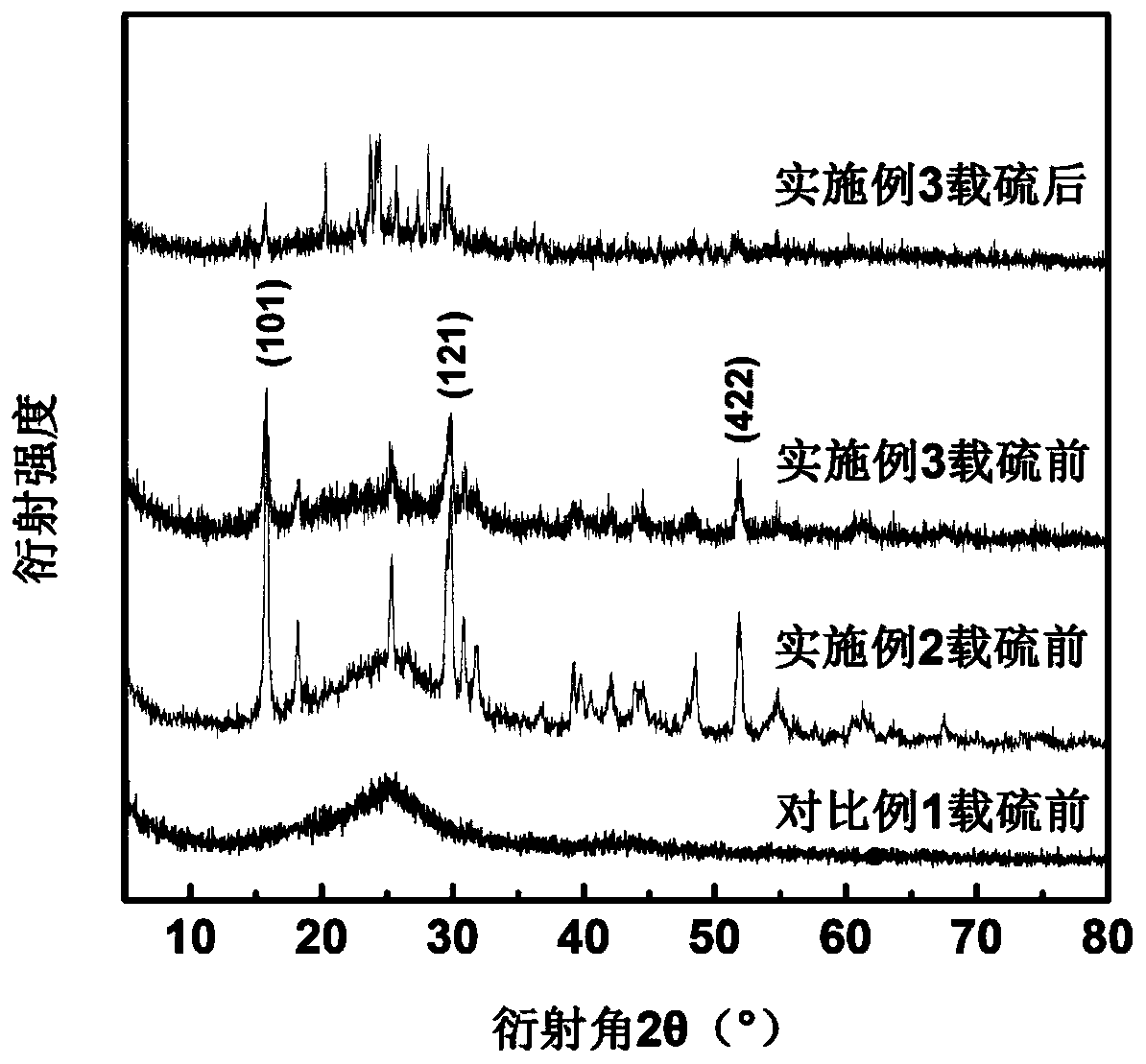

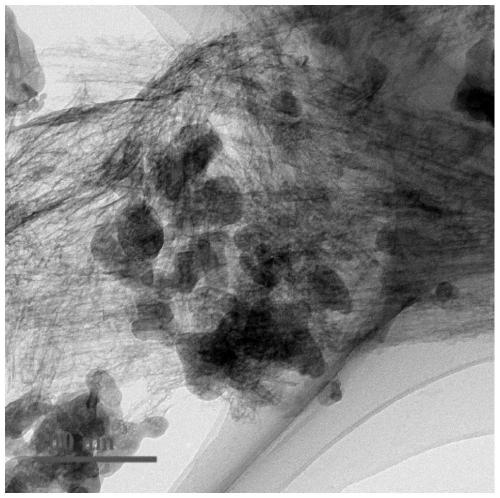

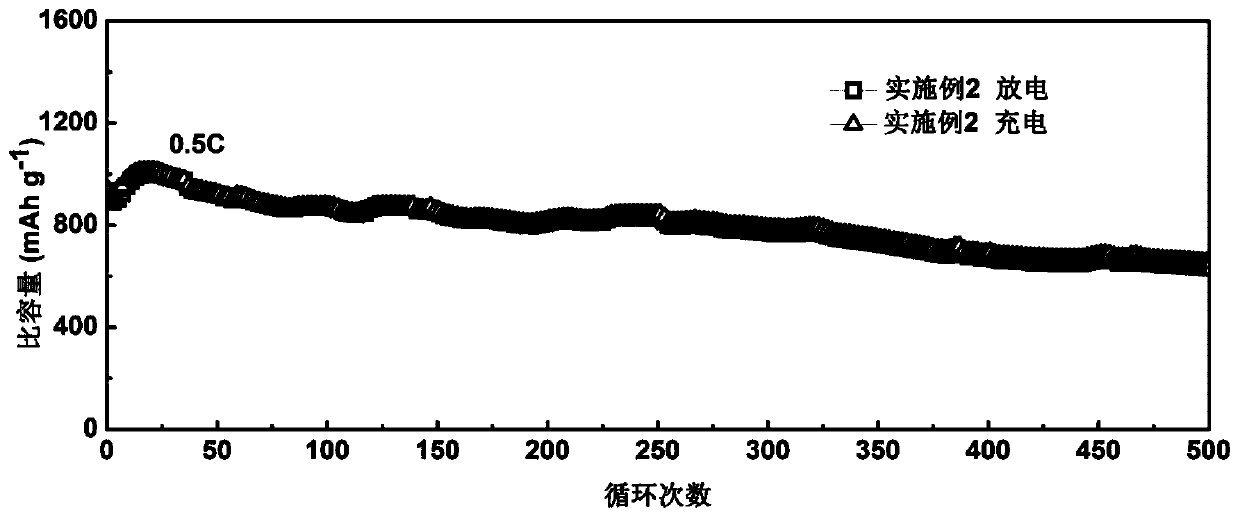

Embodiment 2

[0059] (1) Treatment of attapulgite

[0060] The natural attapulgite was screened with a 200-mesh sieve, and then 6 g of attapulgite was put into 200 mL of hydrochloric acid with a concentration of 6 mol / L, and heated and stirred at 70 ° C for 4 h. Then carry out suction filtration, the product obtained after suction filtration is washed to neutrality, and then the obtained sample is placed in a vacuum drying oven to dry for 12 hours.

[0061] (2) Attapulgite-coated nitrogen-doped carbon

[0062] Weigh the above 2g of modified attapulgite, 1.5g of glucose and 1.35g of ammonium chloride into a 100mL beaker, add 40mL of deionized water and continue to stir for 24h, and then put it in a water bath at 80°C until the water is evaporated to obtain the precursor. The above precursor was calcined in a tube furnace under an argon atmosphere at a heating rate of 6°C / min, and calcined at 900°C for 7h to obtain a nitrogen-doped carbon-coated attapulgite composite.

[0063] (3) HF treatm...

Embodiment 3

[0072] (1) Treatment of attapulgite

[0073] The natural attapulgite was screened with a 200-mesh sieve, and then 6 g of attapulgite was put into 200 mL of hydrochloric acid with a concentration of 6 mol / L, and heated and stirred at 80 ° C for 3 h. Then carry out suction filtration, the product obtained after suction filtration is washed to neutrality, and then the obtained sample is placed in a vacuum drying oven to dry for 12 hours.

[0074] (2) Attapulgite-coated nitrogen-doped carbon

[0075] Weigh the above-mentioned 2g of modified attapulgite, 2g of glucose and 1.2g of ammonium chloride into a 100mL beaker, add 40mL of deionized water and keep stirring for 24h, and then put it in a water bath at 80°C until the water is evaporated to obtain the precursor. The above precursor was calcined in a tube furnace under an argon atmosphere at a heating rate of 5°C / min, and calcined at 800°C for 5h to obtain a nitrogen-doped carbon-coated attapulgite composite.

[0076] (3) HF tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com