Degradation method of livestock and poultry manure antibiotics

A technology of livestock and poultry manure and antibiotics, applied in the field of degradation of livestock and poultry manure antibiotics, can solve the problems of long time, difficulty in using fermentation residue as fertilizer, and high cost of antibiotics, and achieve efficient and simple effects, which are conducive to crop growth and safe raw materials non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

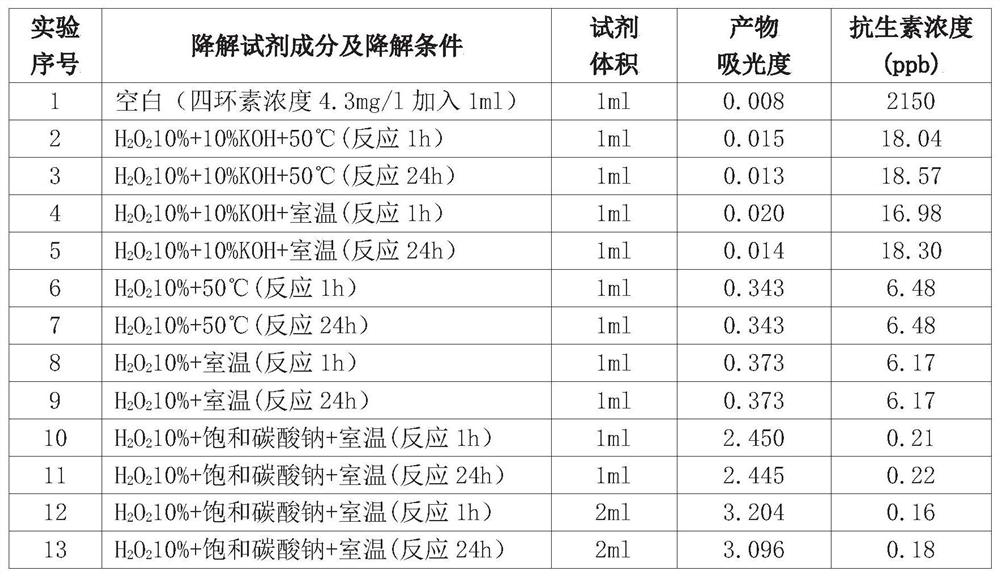

[0031] Embodiment 1: The experiment of degrading tetracycline with the degradation reagent containing hydrogen peroxide

[0032] S1: Prepare 4.3mg / l tetracycline solution, take 1ml and add degradation reagent in a beaker. The composition and amount of degradation reagent are shown in Table 1 below.

[0033] S2: After completing the above steps, perform degradation according to the reaction temperature and reaction time in Table 1, and the degradation reaction is carried out under the stirring condition of a magnetic stirrer.

[0034] S3: After completing the above steps, ultrasonically vibrate for 10-20 minutes, then centrifuge at 3500-4500r / min for 5-10 minutes, get the supernatant and measure, and measure the tetracycline content by ELISA at 450mm with a microplate reader.

[0035] As shown in Table 1, add 1 ml of reagents to 1 ml of tetracycline solution, add 1 ml of distilled water to the blank group numbered 1, and add 1 ml of reagents in numbers 2-9. For the ingredients in...

Embodiment 2

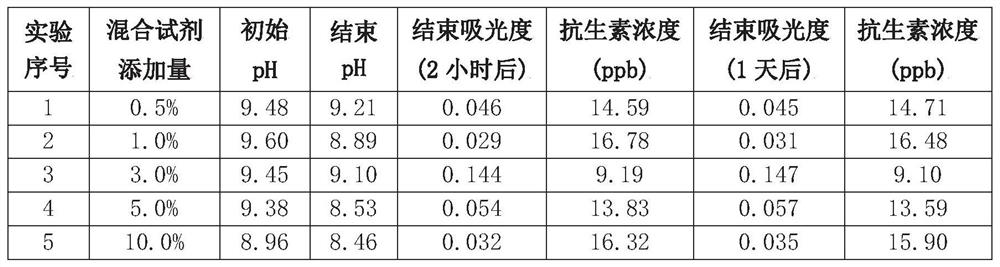

[0039] Embodiment 2: the experiment of different concentrations of hydrogen peroxide degrading livestock and poultry feces antibiotics

[0040] S1: Collect 20g of chicken manure fermented to a water content of 20%wt, add tetracycline solution, and adjust the initial concentration of tetracycline in the manure to be 500ppm.

[0041] S2: Add sodium carbonate-hydrogen peroxide mixed reagent to chicken manure, and react at room temperature for 2 hours. Sodium carbonate in the sodium carbonate-hydrogen peroxide mixed reagent is in a saturated state (mass concentration is 18.1%), and the concentration of hydrogen peroxide is 30wt%.

[0042] S3: The supernatant was taken for ultrasonic vibration for 20 minutes, then centrifuged at 4500 r / min for 10 minutes, and the supernatant was taken for determination. The content of tetracycline was determined by ELISA method with a microplate reader at 450 mm.

[0043] Table 2 Experimental conditions and results of antibiotic degradation in ch...

Embodiment 3

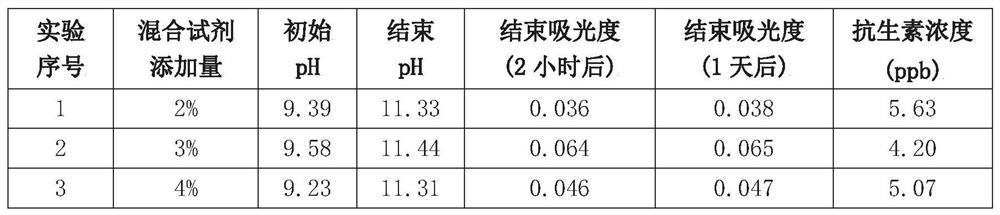

[0046] Embodiment 3: the experiment of different addition amount of sodium carbonate-hydrogen peroxide mixed reagent degrades antibiotic

[0047] S1: Collect 20g of chicken manure fermented to a water content of 10%wt, add tetracycline solution, and adjust the initial concentration of tetracycline in the manure to be 250ppm.

[0048] S2: Add sodium carbonate-hydrogen peroxide mixed reagent to chicken manure, and react at room temperature for 2 hours. Sodium carbonate in the sodium carbonate-hydrogen peroxide mixed reagent is in a saturated state (mass concentration is 18.1%), and the concentration of hydrogen peroxide is 30wt%.

[0049] S3: Add 0.1M hydrochloric acid:methanol (50ml:50ml) extractant after completion of the reaction to extract antibiotics, add extractant according to the amount of extractant:chicken manure=2:1 (v / m).

[0050] S4: The supernatant was taken for ultrasonic vibration for 20 minutes, then centrifuged at 4500 r / min for 10 minutes, and the supernatant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com