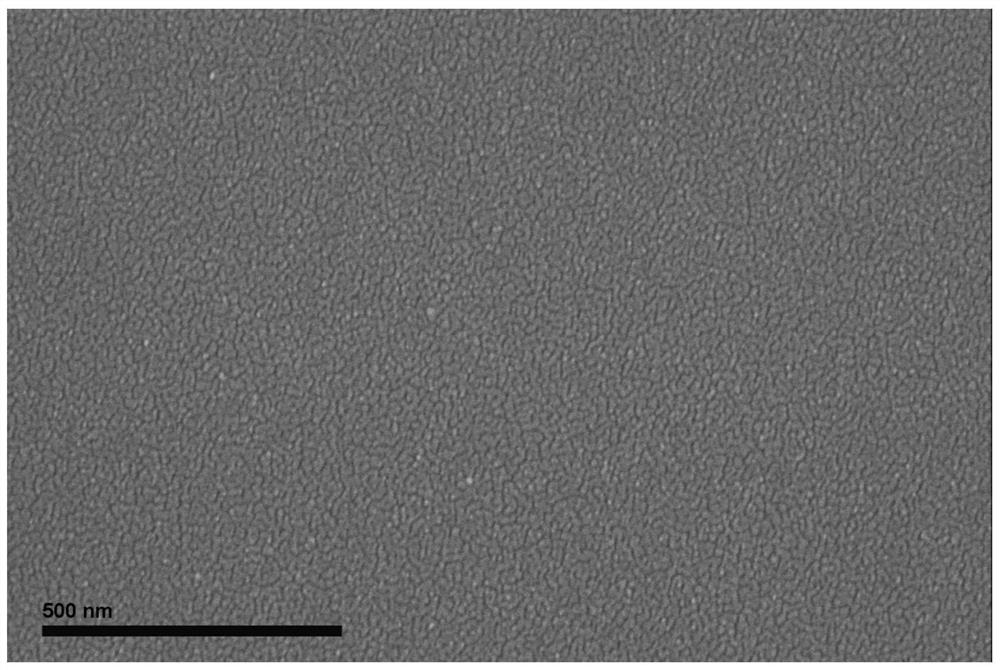

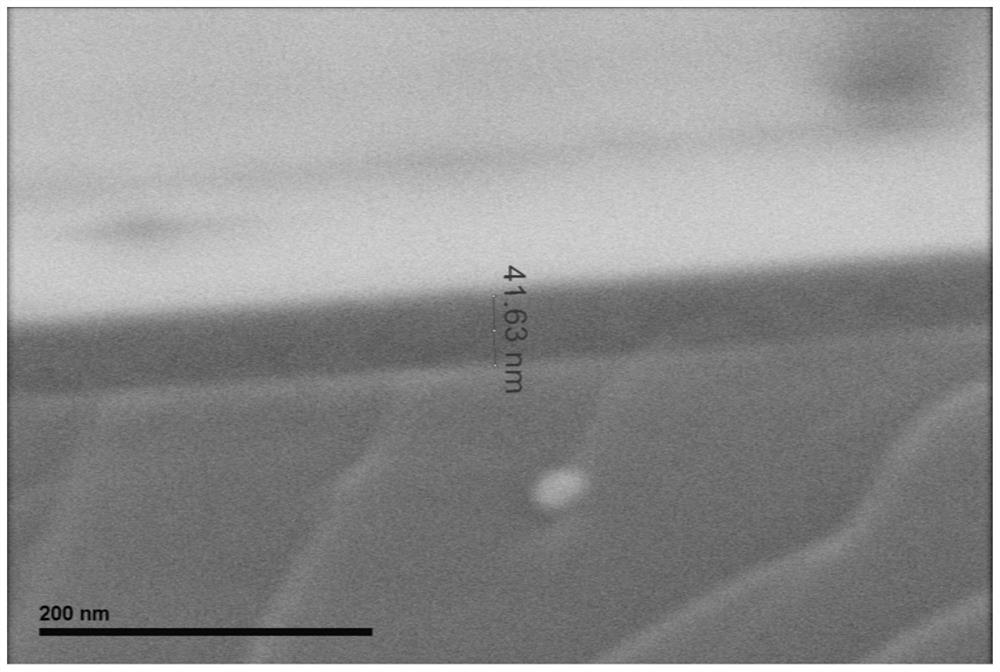

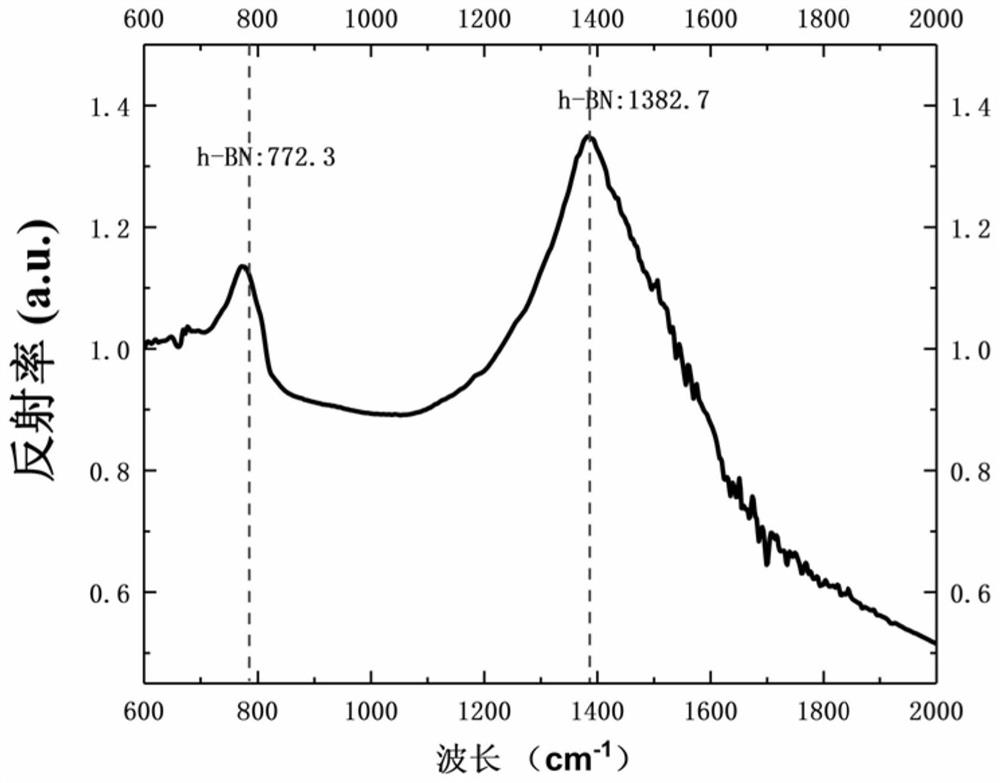

Hexagonal boron nitride thick film based on ion beam sputtering deposition, preparation method and application

A boron nitride thick film, ion beam sputtering technology, used in sputtering coating, ion implantation coating, coating and other directions, can solve the problem of poor substrate adhesion, poor material quality, poor device performance, etc. problems, to avoid sample damage and device performance degradation, high crystallinity, and improve phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A hexagonal boron nitride thick film deposited based on ion beam sputtering and its preparation method and application, (1) the specific steps of providing a substrate include: 1) cutting an N-type silicon wafer (100) of required size; 2 ) Put the sliced silicon wafer into boiling petroleum ether for 2 minutes (petroleum ether boiling point: 80-90°C), then ultrasonically clean it with acetone, and then rinse it with deionized water; 3) Put boiling ammonia water, hydrogen peroxide and In the mixture of deionized water for 2 minutes (the boiling point of the mixture: 60 ° C), the ratio of ammonia water, hydrogen peroxide and deionized water is 1:2:5, and then rinse with deionized water; 4) Put boiling hydrochloric acid, hydrogen peroxide and In the mixture of deionized water for 2 minutes (the boiling point of the mixture: 90°C), the ratio of hydrochloric acid, hydrogen peroxide and deionized water is 1:2:8. After taking it out, rinse it with deionized water; 5) soak it...

Embodiment 2

[0041] A hexagonal boron nitride thick film deposited based on ion beam sputtering and its preparation method and application, (1) the specific steps of providing a substrate include: 1) cutting an N-type silicon wafer (100) of required size; 2 ) Put the sliced silicon wafer into boiling petroleum ether for 2 minutes (petroleum ether boiling point: 80-90°C), then ultrasonically clean it with acetone, and then rinse it with deionized water; 3) Put boiling ammonia water, hydrogen peroxide and In the mixture of deionized water for 2 minutes (the boiling point of the mixture: 60 ° C), the ratio of ammonia water, hydrogen peroxide and deionized water is 1:2:5, and then rinse with deionized water; 4) Put boiling hydrochloric acid, hydrogen peroxide and In the mixture of deionized water for 2 minutes (the boiling point of the mixture: 90°C), the ratio of hydrochloric acid, hydrogen peroxide and deionized water is 1:2:8. After taking it out, rinse it with deionized water; 5) soak it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com