Preparation method of manganese-based metal catalyst for advanced treatment of coal chemical wastewater

A manganese-based catalyst and catalyst technology, applied in water treatment parameter control, oxidized water/sewage treatment, physical/chemical process catalyst, etc., can solve the problem of increasing wastewater treatment costs and environmental pollution risks, crystallized salt must be disposed of as hazardous waste, Evaporation and crystallization can not operate normally, etc., to achieve the effect of stable properties and good reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

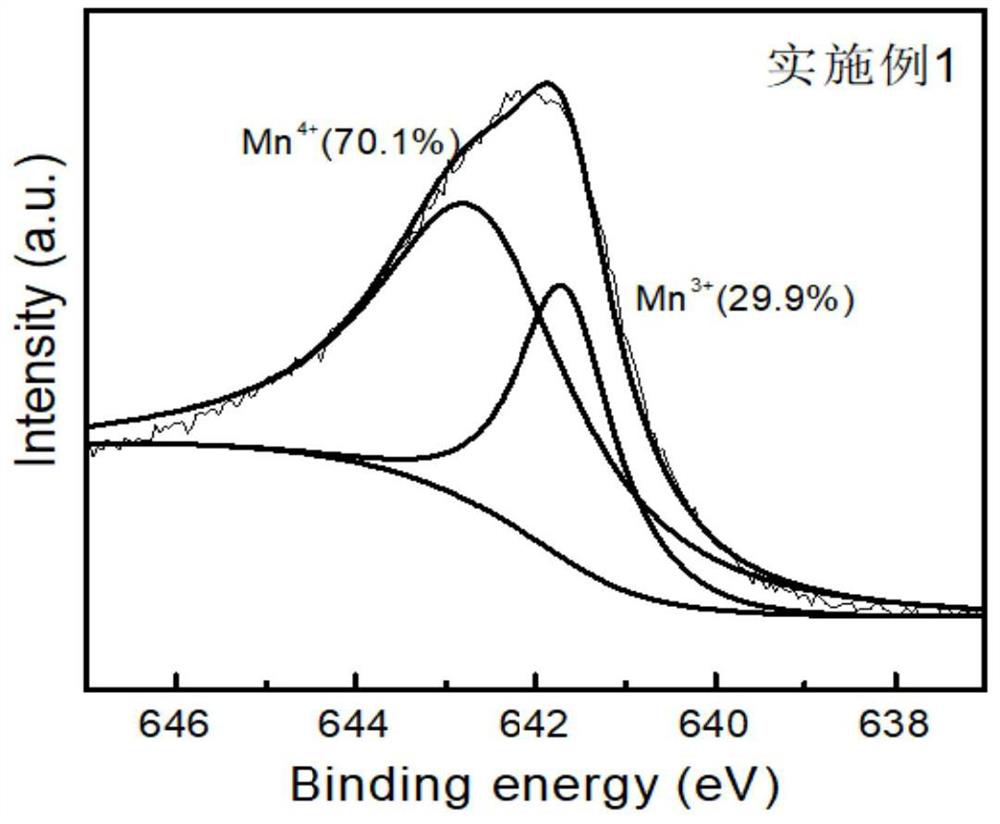

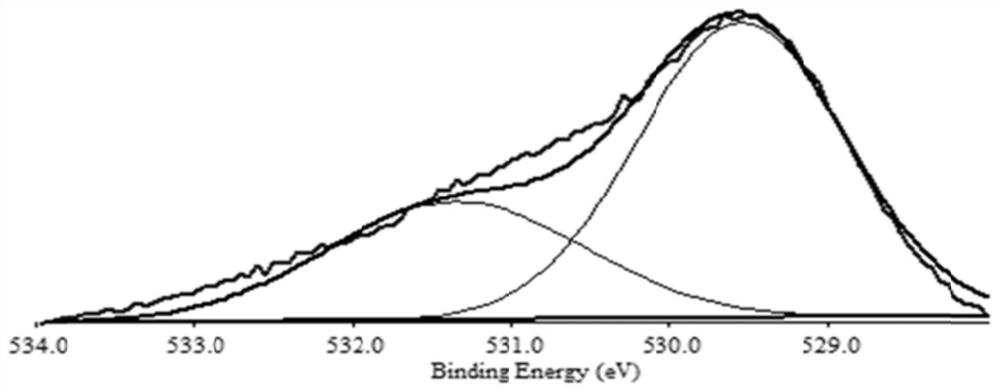

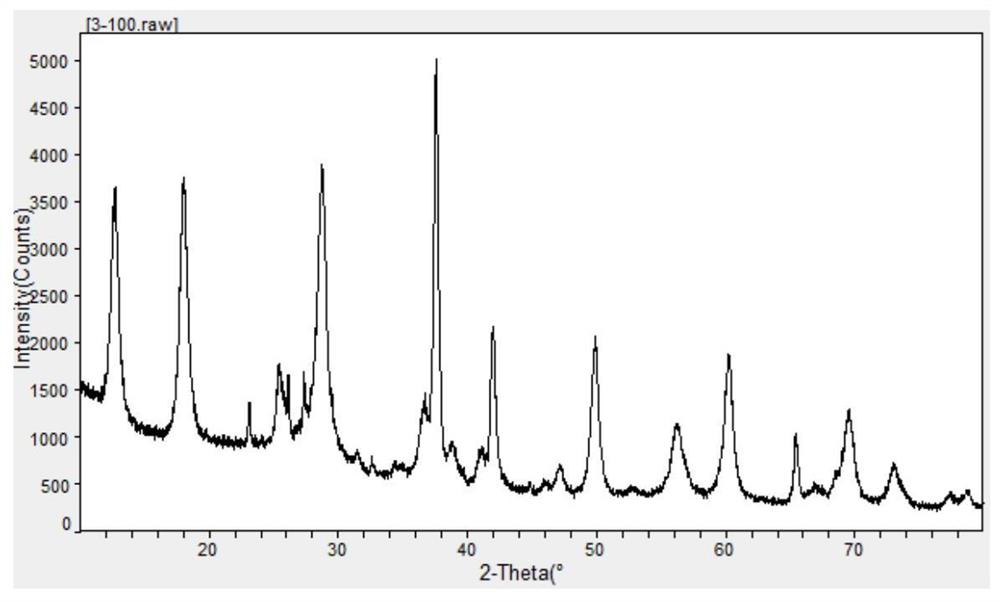

Embodiment 1

[0045] A method for preparing a manganese-based metal catalyst for advanced treatment of coal chemical wastewater, comprising the following steps:

[0046] In this example, the molar ratio of potassium permanganate: manganese sulfate: manganese acetate: magnesium nitrate: iron nitrate was adjusted to 1:0.9:0.1:0.05:0.03, and the catalyst was synthesized by hydrothermal synthesis.

[0047] (1) prepare 1M solutions respectively according to the molar ratio mentioned above;

[0048] (2) under the rotating speed of 50rpm, the potassium permanganate prepared in the step (1) is added dropwise in the manganese sulfate solution and then dripped the manganese acetate solution therein, drips magnesium nitrate, ferric nitrate solution under rapid stirring state, The mixed solution was reacted for 30min at a rotating speed of 50rpm;

[0049] (3) Transfer the mixed solution in step (2) to a hydrothermal reaction kettle, set the temperature to 140°C, the rotation speed to 8rpm, and the react...

Embodiment 2

[0057] A method for preparing a manganese-based metal catalyst for advanced treatment of coal chemical wastewater, comprising the following steps:

[0058] In this embodiment, the molar ratio of potassium permanganate: manganese sulfate: manganese acetate: magnesium nitrate: iron nitrate was adjusted to 1:1:0.15:0.05:0.03, and the catalyst was synthesized by hydrothermal synthesis method.

[0059] (1) prepare 1M solutions respectively according to the molar ratio mentioned above;

[0060] (2) under the rotating speed of 50rpm, the potassium permanganate prepared in the step (1) is added dropwise in the manganese sulfate solution and then dripped the manganese acetate solution therein, drips magnesium nitrate, ferric nitrate solution under rapid stirring state, The mixed solution was reacted for 30min at a rotating speed of 50rpm;

[0061] (3) Transfer the mixed solution in step (2) to a hydrothermal reaction kettle, set the temperature to 140°C, the rotation speed to 8rpm, an...

Embodiment 3

[0069] A method for preparing a manganese-based metal catalyst for advanced treatment of coal chemical wastewater, comprising the following steps:

[0070] In this example, the molar ratio of potassium permanganate: manganese sulfate: manganese acetate: magnesium nitrate: iron nitrate was adjusted to 1:1:0.15:0.06:0.04, and the catalyst was synthesized by hydrothermal synthesis method.

[0071] (1) prepare 1M solutions respectively according to the molar ratio mentioned above;

[0072] (2) under the rotating speed of 50rpm, the potassium permanganate prepared in the step (1) is added dropwise in the manganese sulfate solution and then dripped the manganese acetate solution therein, drips magnesium nitrate, ferric nitrate solution under rapid stirring state, The mixed solution was reacted for 30min at a rotating speed of 50rpm;

[0073] (3) Transfer the mixed solution in step (2) to a hydrothermal reaction kettle, set the temperature to 140°C, the rotation speed to 8rpm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com