Anti-mud amphoteric polycarboxylate superplasticizer and preparation method thereof

A technology of amphoteric polycarboxylic acid and water reducing agent, applied in the field of water reducing agent, can solve the problems of large slump loss, pollution, low sensitivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

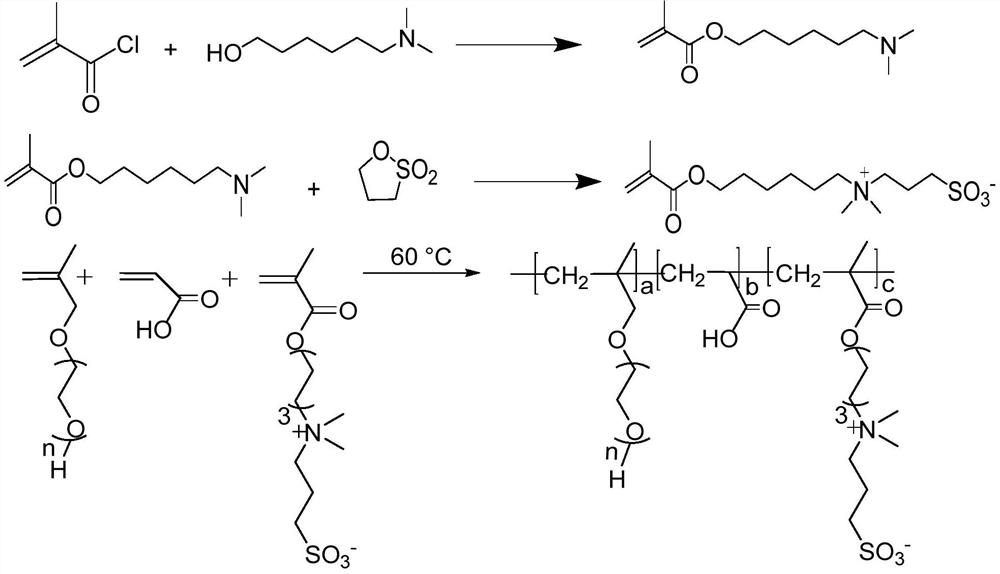

Method used

Image

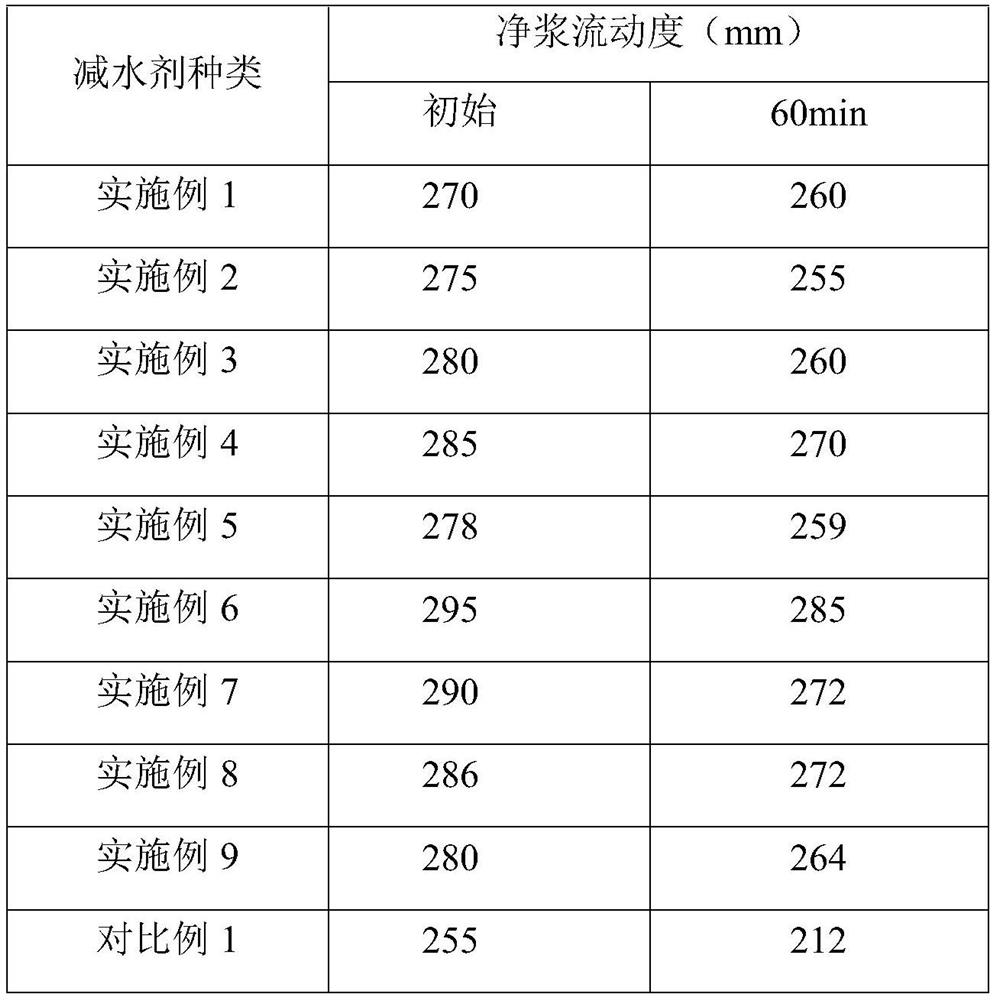

Examples

Embodiment 1

[0054] (1) Preparation of methacrylate-6-dimethylaminohexyl ester intermediate: add 21.9732g of 6-dimethylamino-1-hexanol and 100mL ether to a three-necked round-bottomed flask, and control the temperature to 0°C; Add methacryloyl chloride dropwise to the three-necked round-bottomed flask for 40 minutes, react for 3 hours, and stop the reaction; wash the oil layer with deionized water for 3 times, then add desiccant anhydrous calcium chloride, and dry overnight , filtered, and the filtrate was rotary evaporated at 35°C, and the organic solvent ether was removed to obtain the intermediate of 6-dimethylaminohexyl methacrylate, which was set aside.

[0055] (2) Preparation of amphoteric monomer: add 2.7670g of 6-dimethylaminohexyl methacrylate intermediate prepared in step (1), 0.0390g of hydroquinone and 30mL of acetone into a three-neck round bottom flask, Stir to dissolve and heat up to 50°C; add 1.2203g 1,3-propane sultone into 10mL acetone to obtain 1,3-propane sultone dropw...

Embodiment 2

[0058] (1) The preparation of 6-dimethylaminohexyl methacrylate intermediate and amphoteric monomer is the same as in Example 1.

[0059] (2) Add 35mL of deionized water, 24.06g of methacryl alcohol polyoxyethylene ether (molecular weight: 2400) and 0.1178g of hydrogen peroxide into a 150mL three-neck round bottom flask, stir and dissolve, and heat up to 65°C to obtain a mixed solution; 2.1796g of acrylic acid and 0.6745g of the amphoteric monomer prepared in step (1) were dissolved in 10mL of deionized water to prepare drop solution A; 0.0332g of ascorbic acid and 0.1007g of thioglycolic acid were dissolved in 15mL of deionized water to prepare Obtain dropwise solution B; then begin to dropwise add A and B in the mixed solution under the condition of constant temperature oil bath 65 ℃ and stirring, wherein the dropwise addition time of solution A, B is 3 hours and 3.5 hours respectively, dropwise After completion, keep the reaction for 1 hour. After cooling to room temperatur...

Embodiment 3

[0061] (1) The preparation of 6-dimethylaminohexyl methacrylate intermediate and amphoteric monomer is the same as in Example 1.

[0062] (2) Add 40 mL of deionized water, 24.47 g of methacryl alcohol polyoxyethylene ether (molecular weight: 2400) and 0.1207 g of hydrogen peroxide into a 150 mL three-neck round bottom flask, stir and dissolve, and heat up to 60 ° C to obtain a mixed solution; 3.2034g of acrylic acid and 1.0479g of the amphoteric monomer prepared in step (1) were dissolved in 10mL of deionized water to prepare drop solution A; 0.0351g of ascorbic acid and 0.1172g of thioglycolic acid were dissolved in 15mL of deionized water to prepare Obtain dropwise liquid B; then begin to drip A and B in the mixed solution under the condition of constant temperature oil bath 60 ℃ and stirring, wherein the time for adding dropwise liquid A, B is 3 hours and 3.5 hours respectively, dropwise After completion, keep the reaction for 1 hour. After cooling to room temperature, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com