A carbon nitride/lanthanum hydroxide nanofiber membrane and its preparation method and application

A technology of nanofiber membrane and lanthanum hydroxide, which is applied in the field of photocatalytic materials, can solve the problems of easy agglomeration of carbon nitride, low utilization rate of visible light, and cumbersome post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

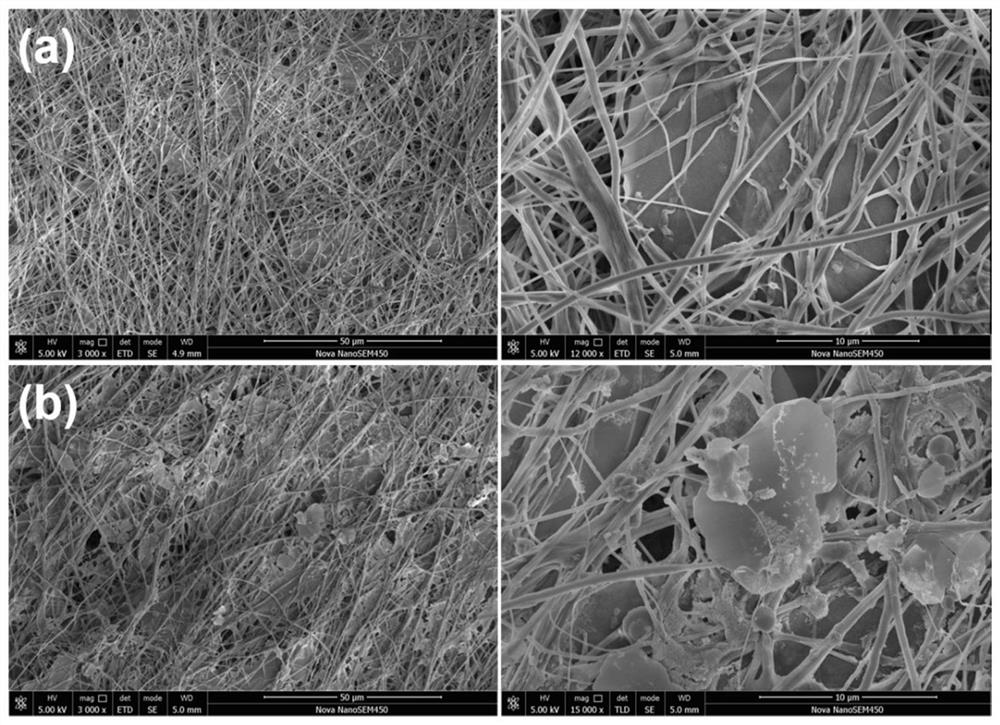

[0038] Preparation of carbon nitride / lanthanum hydroxide nanofiber membrane (with cotton fiber as substrate):

[0039] (1) Preparation of carbon nitride: put a certain amount of urea in a crucible with a cover, raise the temperature to 550°C at a heating rate of 2°C / min, heat cure and peel in air for 4h, and obtain yellow carbon nitride powder.

[0040] (2) Preparation of spinning solution: Soak cotton in water, methanol and dimethylacetamide successively for 1 hour activation respectively, then filter the activation solution by suction filtration, fully dissolve the polymer matrix after suction filtration in DMAC / In the LiCl (mixed solvent of mass ratio 92:8) solvent system, obtain the cellulose spinning solution that mass concentration is 1%; Add the carbon nitride of cotton quality 10% and spinning solution quality 0.5 in the cellulose spinning solution % lanthanum chloride, fully stirred at room temperature for 12h and mixed evenly.

[0041](3) One-step preparation of ca...

Embodiment 2

[0052] Preparation of carbon nitride / lanthanum hydroxide nanofiber membrane (based on chitosan):

[0053] (1) Preparation of carbon nitride: put a certain amount of urea in a crucible with a cover, raise the temperature to 550°C at a heating rate of 2°C / min, heat cure and peel in air for 4h, and obtain yellow carbon nitride powder.

[0054] (2) Configuration of spinning solution: soak the chitosan matrix in water, methanol, and dimethylacetamide successively for 1.5 hours to activate respectively, then suction filter, and fully dissolve the polymer matrix after the suction filtration in DMAC / In LiCl (mass ratio 92:8) solvent system, obtain the chitosan spinning solution of mass concentration 1%; Add the carbon nitride of chitosan quality 20% and spinning solution quality 1% in chitosan spinning solution % lanthanum sulfate, fully stirred at room temperature for 12h and mixed evenly.

[0055] (3) One-step preparation of carbon nitride / lanthanum hydroxide nanofiber membrane: p...

Embodiment 3

[0057] Preparation of carbon nitride / lanthanum hydroxide nanofiber membrane (using polyvinyl alcohol as the base material):

[0058] (1) Preparation of carbon nitride: put a certain amount of melamine in a crucible with a cover, heat up to 550°C at a heating rate of 2°C / min, and heat-cure and peel in air for 4 hours to obtain yellow carbon nitride powder.

[0059] (2) Configuration of spinning solution: The hydrogen bonds between polyvinyl alcohols are weak, and the activation process can be ignored. Directly dissolve polyethylene in isopropanol / water (7 / 3, v / v) solvent system to obtain the mass concentration It is a 1.5% polyvinyl alcohol solution; add 30% of the mass of polyvinyl alcohol, 1% of the mass of carbon nitride spinning solution, and 1% of lanthanum nitrate to the polyvinyl alcohol spinning solution, and stir well at room temperature for 12 hours to mix evenly.

[0060] (3) One-step preparation of carbon nitride / lanthanum hydroxide nanofiber membrane: put the chito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com