Preparation method of carbon-based composite material capable of catalytically degrading various organic matters at room temperature, and testing device

A composite material and catalytic degradation technology, which is applied in the field of preparation of carbon-based composite materials, can solve the problems such as being unsuitable for low-concentration organic compounds, incapable of being non-toxic and harmless, and unsatisfactory photocatalytic degradation performance, and achieving catalytic degradation ability. Strong, low cost, good removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of the first modified metal oxide 1:

[0029] a. Add 0.01mol of silver nitrate and 0.01mol of zinc nitrate and 20g of molybdenum oxide into water respectively, stir well, transfer the mixture to a high-pressure reactor and react at 200°C for 12 hours, wash to neutral after cooling, and obtain the first modification Sexual metal oxide 1;

[0030] Preparation of modified metal oxide 2:

[0031]b. Add 0.05mol of copper nitrate, 50g of titanium dioxide, 50g of manganese dioxide and 50g of zinc oxide into water respectively, stir well, transfer the mixture to an autoclave and react at 300°C for 24 hours, wash to neutral after cooling, and obtain The second modified metal oxide 2;

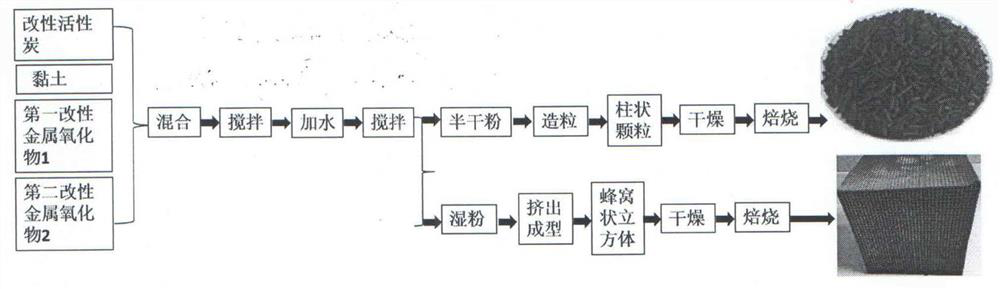

[0032] Preparation of carbon-based composite materials:

[0033] c. According to the mass ratio of 1:0.1:0.1:0.1, respectively weigh the raw material modified cotton stalk activated carbon, bentonite, the first modified metal oxide 1 obtained in step a and the second modified metal ...

Embodiment 2

[0037] Preparation of the first modified metal oxide 1:

[0038] a. Add 0.01mol of silver nitrate and 0.01mol of zinc nitrate and 20g of molybdenum oxide into water respectively, stir well, transfer the mixture to a high-pressure reactor and react at 200°C for 12 hours, wash to neutral after cooling, and obtain the first modification Sexual metal oxide 1;

[0039] Preparation of the second modified metal oxide 2:

[0040] b. Add 0.05mol ferric nitrate, 50g titanium dioxide, 50g manganese dioxide and 50g zinc oxide into water respectively, stir well, transfer the mixture to an autoclave and react at 300°C for 24 hours, wash to neutral after cooling, and obtain The second modified metal oxide 2;

[0041] Preparation of carbon-based composite materials:

[0042] c. According to the mass ratio of 1:0.2:0.3:0.3, weigh the raw material modified fruit wood activated carbon, attapulgite, the first modified metal oxide 1 obtained in step a and the second modified metal oxide obtaine...

Embodiment 3

[0046] Preparation of the first modified metal oxide 1:

[0047] a. Add 0.01mol of silver nitrate and 0.01mol of zinc nitrate and 20g of molybdenum oxide into water respectively, stir well, transfer the mixture to a high-pressure reactor and react at 200°C for 12 hours, wash to neutral after cooling, and obtain the first modification Sexual metal oxide 1;

[0048] Preparation of the second modified metal oxide 2:

[0049] b. Add 0.05mol of nickel nitrate, 50g of titanium dioxide, 50g of manganese dioxide and 50g of zinc oxide into water respectively, stir well, transfer the mixture to an autoclave and react at 300°C for 24 hours, wash to neutral after cooling, and obtain The second modified metal oxide 2;

[0050] Preparation of carbon-based composite materials:

[0051] c. According to the mass ratio of 1:0.3:0.4:0.4, weigh the raw material modified apricot shell activated carbon, bentonite, the first modified metal oxide 1 obtained in step a and the second modified metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com