Preparation method of composition containing spirulina polysaccharide extract

A technology of spirulina polysaccharides and extracts, applied in medical preparations containing active ingredients, skin care preparations, pharmaceutical formulas, etc., can solve the problems of retinal cell damage, vision loss, loss, etc., to promote metabolism and reduce damage , good heat-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of Spirulina Polysaccharide Powder:

[0032] extract:

[0033] 1. Weighing: Weigh 10.00g spirulina powder into a 500ml beaker

[0034] 2. Dissolution: add deionized water to the beaker at a ratio of 1:25 (g / ml)

[0035] 3. Freezing and thawing treatment: freeze at -20°C for 4 hours and take out. Then thaw in a 37°C water bath and repeat this 3 times

[0036] 4. Ultrasound: After thawing is completed, ultrasonicate for 15min at 80Hz

[0037] 5. Extraction: After ultrasonication, the extraction was carried out at a constant temperature of 90 °C for 3 hours.

[0038] 6. Centrifugation: Centrifuge the extract at 3000r / min for 10min, take the supernatant

[0039] 7. Concentration: the extract was concentrated under reduced pressure at 70°C to obtain a concentrate

[0040] 8. Alcohol precipitation: then use 5 times the volume of the concentrated solution for alcohol precipitation with 95% ethanol overnight, centrifuge at 3000 r / min for 10 min, tak...

Embodiment 2

[0049] Example 2: Preparation of cream:

[0050] raw material:

[0051] Caprylic acid triglyceride: purchased from the Making Cosmetics website (trade name Triglyceride)

[0052] Tocopheryl acetate: purchased from the website of Making Cosmetics (trade name Vitamin E (dl-alphatocopheryl acetate)

[0053] Glyceryl stearate, polyethylene glycol-100 stearate: available from the website of Making Cosmetics (trade name BLEND)

[0054] Sodium acrylate / sodium acryloyl taurate copolymer, isohexadecane, polysorbate 80: purchased from the website of MakingCosmetics (trade name EMU)

[0055] Jojoba Oil: Purchased from the Making Cosmetics website (trade name Jojoba Oil, USDA Certified Organic)

[0056] Avocado oil: purchased from the Making Cosmetics website (trade name Avocado Butter)

[0057]Glycerin: purchased from the Making Cosmetics website (trade name Glycerin)

[0058] Cetearyl Alcohol: purchased from Source Leaf Bio

[0059] Sodium pyrrolidone carboxylate: purchased fr...

Embodiment 3

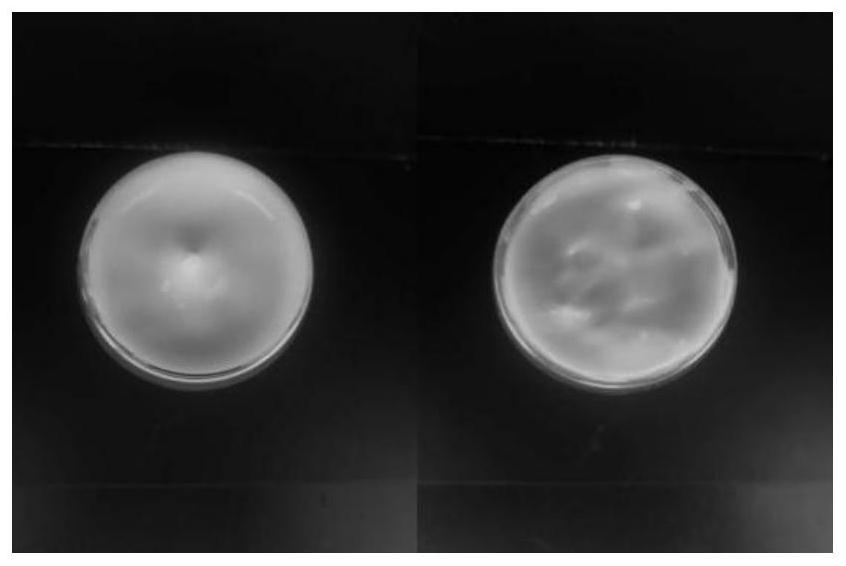

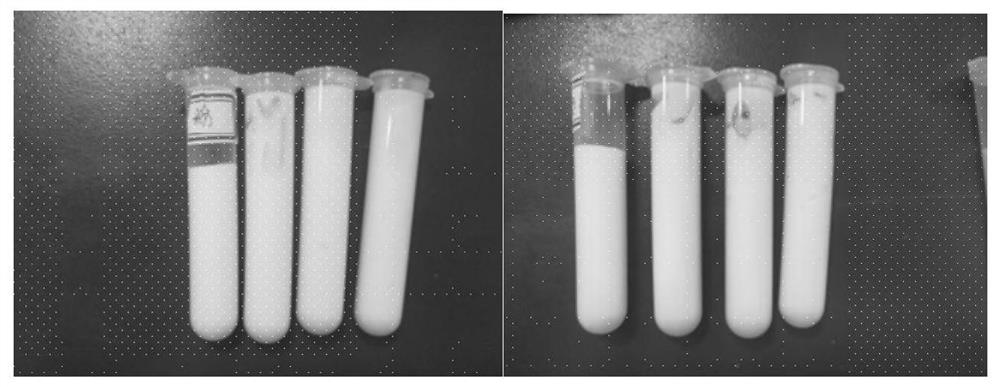

[0073] Example 3: Stability test, see figure 2

[0074] Centrifugation test:

[0075] Process: Put the sample into a centrifuge tube with a scale of 10ml to about 2 / 3 of the height, and pack it firmly, plug it with a lid, and then put it into an electric heating constant temperature incubator pre-adjusted to 40 °C, and keep it for 1 hour. Put the centrifuge tube into the centrifuge to keep the balance, and centrifuge at 2000r / min for 30min to observe whether there is oil-water layer and particles.

[0076] Result: No oily moisture layers, no particles.

[0077] Heat resistance test:

[0078] Process: Put the sample into a sealed centrifuge tube, set the temperature in an incubator at 40°C for 24 hours, and then return to room temperature to observe the discoloration of the liquid and the stratification of oil and water.

[0079] Result: No oily moisture layers, no particles.

[0080] Cold resistance test

[0081] Process: Put the sample into a sealed centrifuge tube, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com