Double-transition metal hierarchical pore catalyst as well as preparation method and application thereof

A technology of transition metals and hierarchical pores, which is applied in the fields of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, carbon-based compound preparation, etc., and can solve the problem of increasing equipment investment costs, high energy consumption and equipment High requirements on cost and catalytic activity to achieve good industrial application prospects, low cost and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of a double-transition metal hierarchical porous catalyst, comprising the steps of:

[0020] After mixing transition metal soluble salts, organosilanes, water and organic acid pore-forming agents in a mass ratio of 1:(15-20):(25-35):(5-15), at 60-90°C React and generate silica gel, after roasting and reducing at 450-550°C, it can be obtained.

[0021] In this embodiment, the transition metal soluble salts are nitrates, chlorides or organic acid salts, and the organosilanes are tetramethoxysilane, tetraethoxysilane, tetrapropoxysilane, orthosilicate tetra One of methyl ester, tetraethyl orthosilicate, tetrabutyl orthosilicate, the organic acid pore-forming agent is oxalic acid, glycolic acid, citric acid, malonic acid, succinic acid, 1,2,3,4 - Butane tetracarboxylic acid, tartaric acid, malic acid, gluconic acid, mucic acid, terephthalic acid, 1,3,5-benzenetricarboxylic acid, 1,2,4,5-benzenetetracarboxylic acid, 2,2-bis One or more mixtures of (hyd...

Embodiment 2

[0024] The double transition metal hierarchical porous catalyst obtained in embodiment 1 can be used for hydrogenation-dehydrogenation coupling reaction,

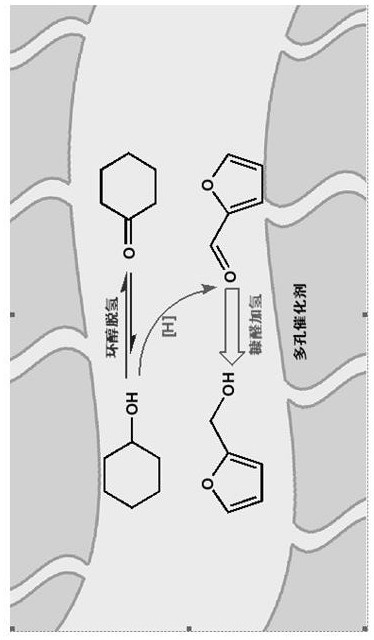

[0025] like figure 1 As shown, the process coupling of furfural hydrogenation and cyclic alcohol dehydrogenation is carried out simultaneously, and the target products furfuryl alcohol and cyclic ketone are produced at the same time. The whole process is realized by a hierarchical porous bimetallic catalyst in the same reactor.

[0026] During operation, the biomass furfural, solvent and cyclic alcohol are mixed, and a double-transition metal hierarchical porous catalyst is added. The weight ratio of the double-transition metal hierarchical porous catalyst to aldehyde and cyclic alcohol is 1: (1.5-6): (3- 12), the hydrogenation-dehydrogenation coupling process of biomass aldehyde-cyclic alcohol occurs under the condition of liquid phase heating, the reaction temperature is 165-210°C, and the reaction time is 4-24 hours; Ce...

Embodiment 3

[0031] After refining the reaction process in Example 2, key reaction parameters with different characteristics can be obtained. This example helps the skilled person understand the influence of the solvent system on the present invention. 1.5g furfural, 4.5g cyclohexanol and 0.5g catalyst (15%Cu-0.5%Pd / SiO 2 ) was added into the autoclave, and 10.5 g of different solvents were added each time, and multiple experiments with different solvents were repeated. Make it react under high-speed magnetic stirring at 195° C. for 10 h. After the reaction is completed, the catalyst and the reaction solution are separated by a high-speed centrifuge. The reaction liquid was analyzed by gas chromatography. The conversion rate of furfural and hydrogen source and the selectivity of hydrogenation product furfuryl alcohol and dehydrogenation product cyclohexanone are shown in Table 1.

[0032] Table 1 The performance of furfural and cyclohexanol to prepare furfuryl alcohol and cyclohexanone w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com