Method for preparing medical wound dressing by microfluidic gas jet spinning method

A wound dressing and spinning technology, applied in the field of medical polymer materials, can solve the problems of poor healing effect, uneven fiber diameter, single composition, etc., and achieve the effect of promoting wound healing, strengthening regeneration ability, and blocking bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

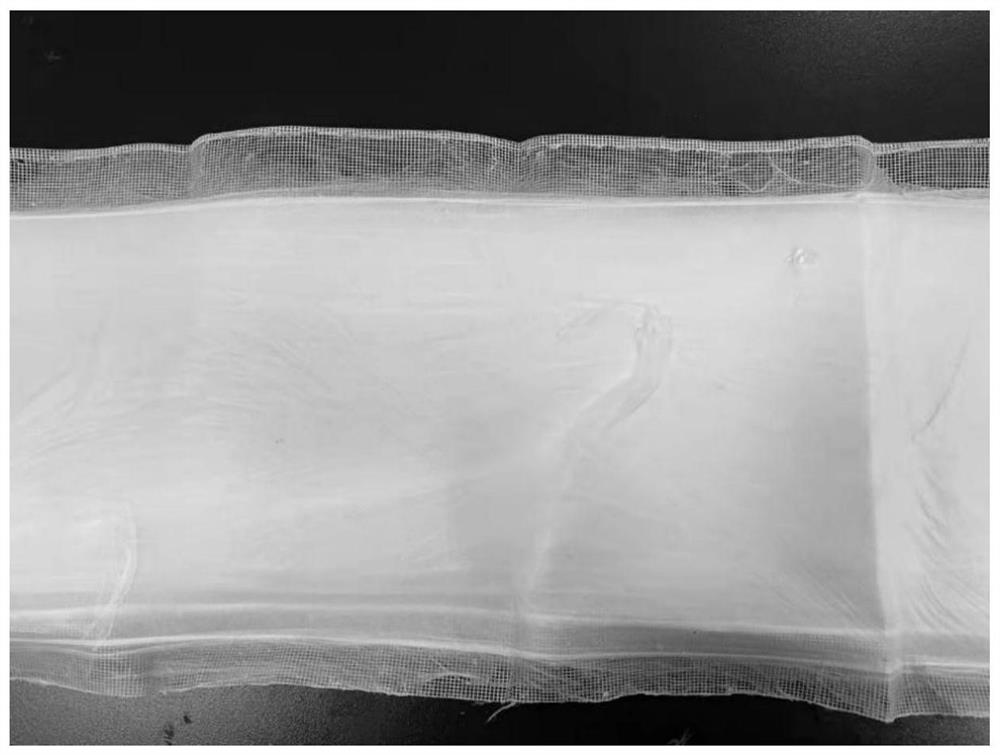

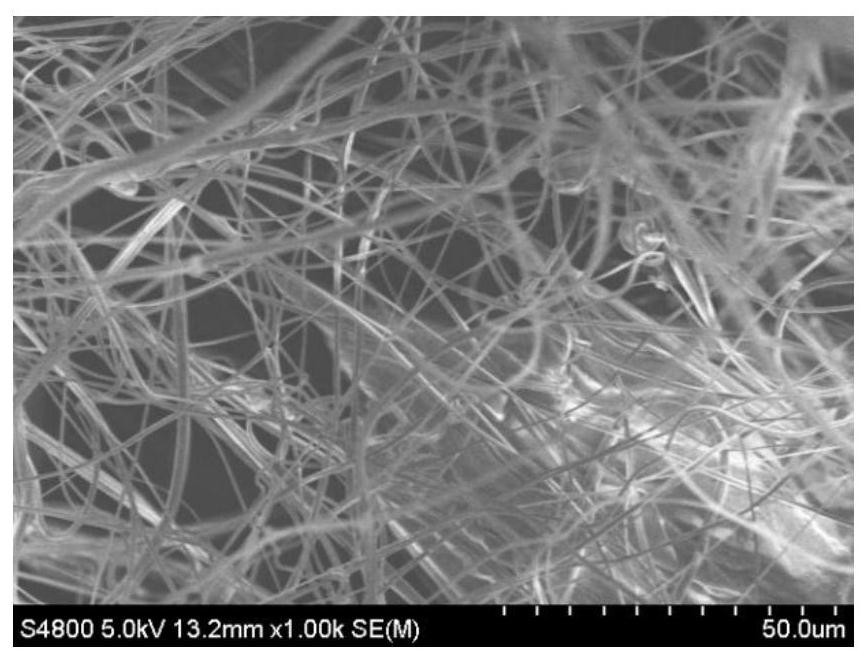

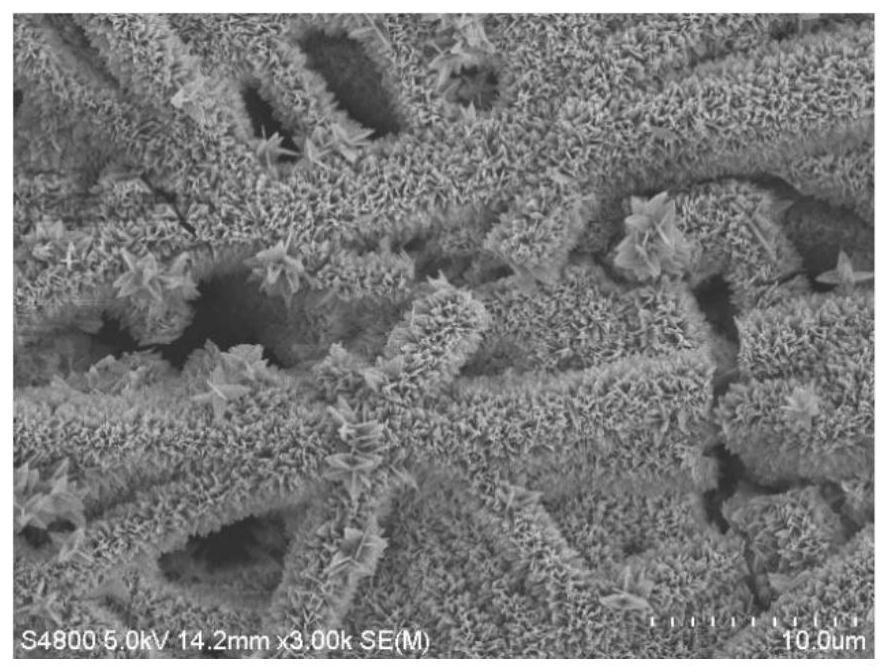

[0028] 16g thermoplastic polyurethane (purchased from BASF) was dissolved in 84g N,N-dimethylformamide to form a polymer A solution with a mass fraction of 16%, and 4.5g zinc acetate was added to the polymer A solution to form a 4.5wt% mixed solution. Transfer the mixed solution into a syringe fitted with a metal needle. 5g of tannic acid was dissolved in 95g of N,N-dimethylformamide to form a polymer B solution with a mass fraction of 5%, and 4.5g of zinc acetate was added to the polymer B solution to form a 4.5wt% mixed solution. Transfer the two mixed solutions of A and B to two 20ml syringes equipped with metal needles, and use a Y-shaped polydimethylsiloxane microfluidic chip with an inner diameter of 0.8mm to separate A and B Mixing, the output rate of the micro-flow pump is set to 5mL / h and 2mL / h respectively, the distance from the needle to the receiver is set to 35cm, the air pump blows the air out of the pinhole with a pressure of 0.1MPa, and the spinning time is 3h...

Embodiment 2

[0031] 15g polycaprolactone was dissolved in 85g 88% formic acid to form a mass fraction of 15% polymer A solution, 7g zinc nitrate hexahydrate was added to form a 7wt% mixed solution in polymer A solution, 10g chitosan was dissolved in 90g 88 % formic acid was dissolved uniformly to form a 10% polymer B solution, and 7g of zinc nitrate hexahydrate was added to the polymer B solution to form a 7wt% mixed solution. Transfer the two mixed solutions of A and B to two syringes equipped with metal needles, and use a T-shaped polydimethylsiloxane microfluidic chip with an inner diameter of 0.4mm to mix A and B during spinning , set the output rate of the micro-flow pump to 5mL / h and 5mL / h respectively, set the distance from the needle to the receiver to 30cm, the air pump blows air out of the pinhole at a pressure of 0.1MPa, and the spinning time is 2h , obtain the polycaprolactone / chitosan fiber scaffold on the receiver, the ambient temperature is 28°C, and the humidity is 60%. Th...

Embodiment 3

[0034]15g polycaprolactone was dissolved in 85g 88% formic acid to form a mass fraction of 15% polymer A solution, and 7g zinc nitrate hexahydrate was added to form a 7wt% mixed solution in polymer A solution; 12g silk fibroin was dissolved in 88g 88 % formic acid to form a polymer B solution with a mass fraction of 12%, and 7g of zinc nitrate hexahydrate was added to the polymer B solution to form a 7wt% mixed solution. Transfer the two mixed solutions of A and B to two syringes equipped with metal needles, and use a Y-shaped polydimethylsiloxane microfluidic chip with an inner diameter of 0.2mm to mix A and B during spinning , set the output rate of the micro-flow pump to 3mL / h and 5mL / h respectively, set the distance from the needle to the receiver to 28cm, the air pump blows air out of the pinhole at a pressure of 0.2MPa, and the spinning time is 4h , to obtain a polycaprolactone / silk fibroin composite fiber scaffold on the receiver. The ambient temperature is 30°C, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com