Method for producing complex microbial inoculant through fermentation of clostridium butyricum centrifugal waste liquid, corresponding complex microbial inoculant and application of complex microbial inoculant

The technology of a compound bacterial agent and clostridium butyricum is applied in the field of microbial bacterial agent and aquaculture, which can solve the problems of increasing the burden on enterprises and environmental protection, small market demand, difficult preservation, etc., and achieves stable production and good convenience, Improve the industrial chain, the effect of not easy to contaminate bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

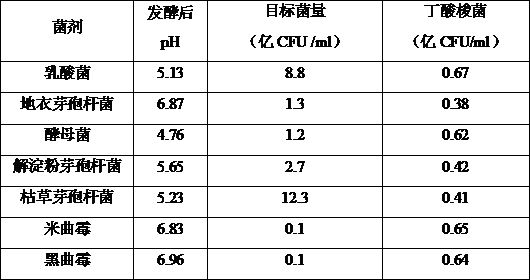

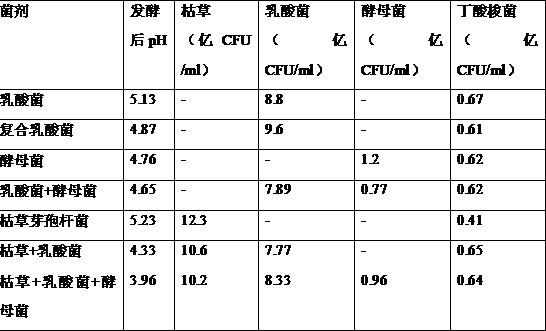

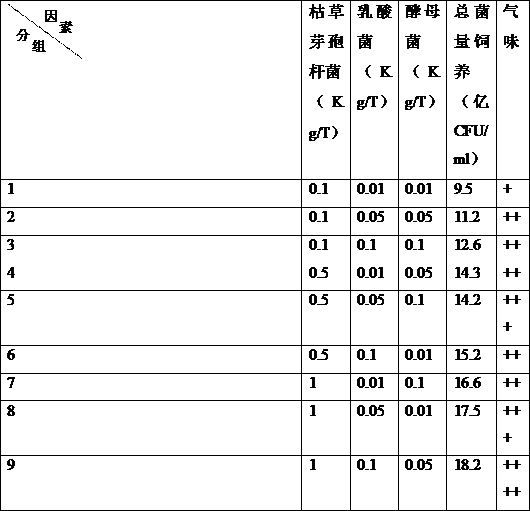

[0033] The present invention utilizes Clostridium butyricum centrifuge waste liquid and fermentation bacterial agent to jointly produce and prepare a kind of composite bacterial agent, the screening process of the specific operation parameter condition in the production process is as follows:

[0034] 1. Addition ratio of Clostridium butyricum centrifugate

[0035] The frozen Clostridium butyricum was inoculated in RCM liquid medium, anaerobically cultured at 37°C until the cell production was over 90%, the fermentation broth was centrifuged at high speed, and the sludge was sent to the next process to make Clostridium butyricum powder. Collect the centrifugate, add water and 4% brown sugar, 0.01% magnesium sulfate, 0.01% manganese sulfate, 0.03% potassium dihydrogen phosphate, 0.02% acetic acid in different proportions (0%, 25%, 50% and 75%) Sodium, adjust pH to 7.0, add compound fermentation agent (0.1% of Bacillus subtilis, 0.1% of Bacillus licheniformis, 0.05% of lactic ac...

Embodiment 2

[0081] Embodiment 2: the water purification effect of composite bacterial agent in aquaculture water body

[0082] 1. Add the compound bacterial agent to the aquaculture water with ammonia nitrogen and pH exceeding the standard at a rate of 5 kg / mu, add the compound bacterial agent every three days, take samples, and test the pH value and ammonia nitrogen in the water.

[0083] The results are shown in Table 9. The pH index of the aquaculture water returned to normal after the compound bacterial agent was added on the third day, and the ammonia nitrogen index tended to normal on the sixth day.

[0084] Table 9: Changes in water body indicators after adding compound bacterial agents

[0085]

[0086] 2. Add the compound bacterial agent at a ratio of 3kg / mu to the aquaculture water body with normal indicators (this water body had a bloom in the same period last year), add the compound bacterial agent every 7 days, and take samples to detect the pH value and ammonia nitrogen i...

Embodiment 3

[0090] Embodiment 3: the effect of composite bacterial agent in aquatic animal breeding

[0091] 1. Add the compound bacterial agent to the feed at an amount of 50 ml / kg, and feed Penaeus vannamei; at the same time, set up a control group, only feed the feed without adding any compound bacterial agent. Penaeus vannamei was cultured according to the normal feeding mode. The volume of a single group of water tanks was 1m×1m×1m, and 80 prawns were cultured. After 14 days of continuous feeding, the length and survival rate of the two groups of prawns were detected.

[0092] The results are shown in Table 11. Compared with the control group, after 14 days of feeding, the Penaeus vannamei in the compound bacterial agent group obviously grew faster and had a higher survival rate.

[0093] Table 11: Effects of compound bacterial agents on the growth of Penaeus vannamei

[0094]

[0095] 2. Add the compound bacterial agent to the feed at the dosage of 50ml / kg, and feed the grass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com