Regeneration method of catalyst containing manganese oxide molecular sieve

A technology of manganese oxide and molecular sieve, which is applied in the direction of molecular sieve catalyst, catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, etc. Loss and other issues to achieve the effect of improving the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

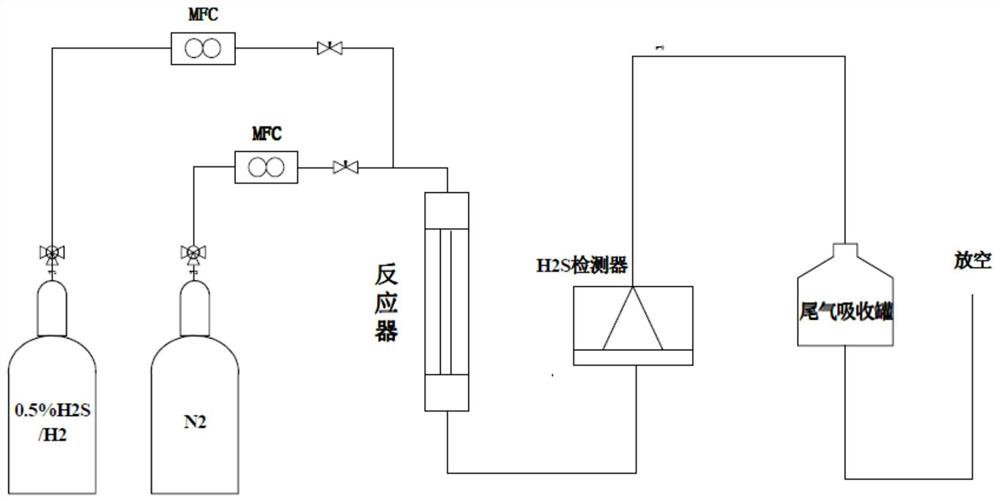

Method used

Image

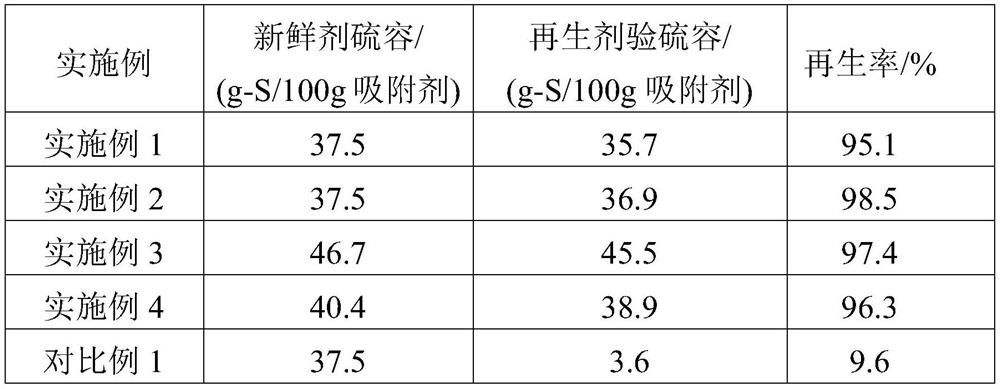

Examples

Embodiment

[0078] Reagents, Instruments and Tests

[0079] Unless otherwise specified, the reagents used in the present invention are analytically pure, and all reagents used are commercially available.

[0080] H used in the present invention 2 The S analysis instrument is a German SICK GMS810 hydrogen sulfide analyzer.

preparation example 1

[0082] Dissolve 3.17g potassium permanganate in 40.55g deionized water, heat and stir to dissolve it to form potassium permanganate solution, mix it with 5.78g of 50% by weight manganese sulfate solution, and add 6ml of nitric acid to adjust the pH value of the solution to 1.0, after stirring evenly, react at 130°C for 24h.

[0083] The resulting brown precipitate was filtered and washed several times with deionized water until the pH of the washing solution was 7, and then the solid product was dried overnight at 120°C, and then roasted at 400°C for 4 hours in an air atmosphere to obtain a manganese oxide molecular sieve. That is, catalyst C1 containing manganese oxide molecular sieve: OMS-2.

preparation example 2

[0085] Dissolve 3.17g potassium permanganate in 40.55g deionized water, heat and stir to dissolve it to form potassium permanganate solution, mix 50% by weight manganese sulfate solution of 5.78g with 1.22g copper nitrate and stir evenly, mix the above two These solutions were mixed, and 6ml of nitric acid was added, stirred evenly, and reacted at 130°C for 24h.

[0086] Filter the resulting brown precipitate and wash it with deionized water several times until the pH of the washing solution is 7, then dry the solid product at 120°C overnight and roast at 400°C for 4 hours to prepare the catalyst C2 containing manganese oxide molecular sieve: 3% CuO- OMS-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com