Preparation method of thermal cross-linked polymer separation membrane and application thereof

A polymer and separation membrane technology, which is applied in separation methods, semipermeable membrane separation, and dispersed particle separation, can solve problems such as yield loss and nanoporous transition layer collapse, and achieve energy saving and separation selectivity coefficient improvement. , The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

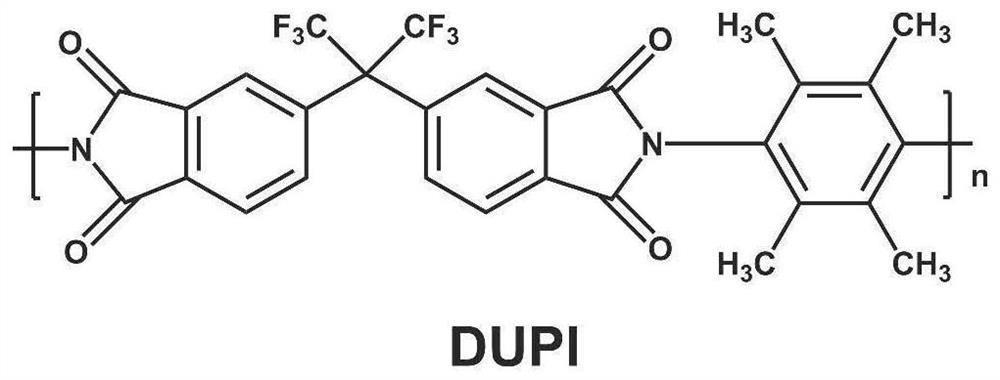

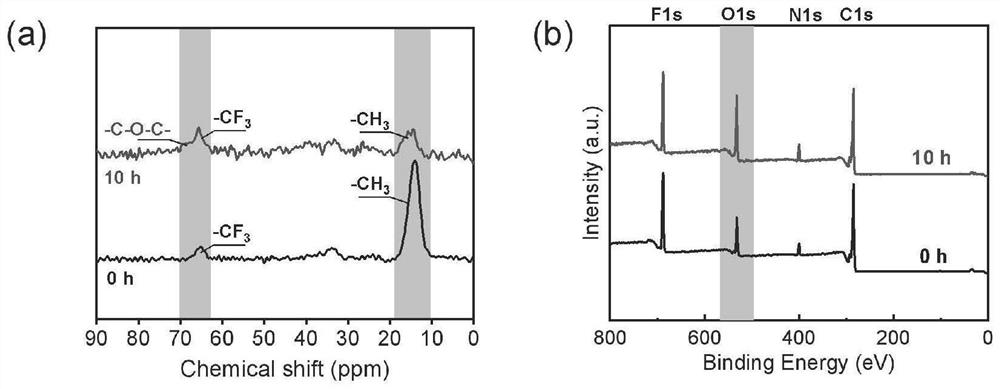

[0043] Synthesis of DUPI: Add 30mmol of benzyldiamine monomer to a three-necked flask equipped with a magnetic stirrer, under nitrogen protection, add an appropriate amount of ultra-dry N-methylpyrrolidone solvent, stir until all solid powder is dissolved, then add 30mmol 4,4'-(hexafluoroisopropylidene) diphthalic anhydride, adding ultra-dry N-methylpyrrolidone solvent to obtain a homogeneous mixed solution with a mass concentration of 20 wt%, and stirring for prepolymerization for 12 hours. During this process, dianhydride and diamine undergo a condensation reaction to open the ring to form polyamic acid. Subsequently, 5-10 mL of anhydrous toluene was added to the system, and a water separator and a spherical condenser were installed on the side neck of the three-necked flask. The water generated in the imine process is removed by azeotropic distillation with toluene, and the reaction proceeds forward. After the reaction was completed, the viscous reaction product solution w...

Embodiment 2

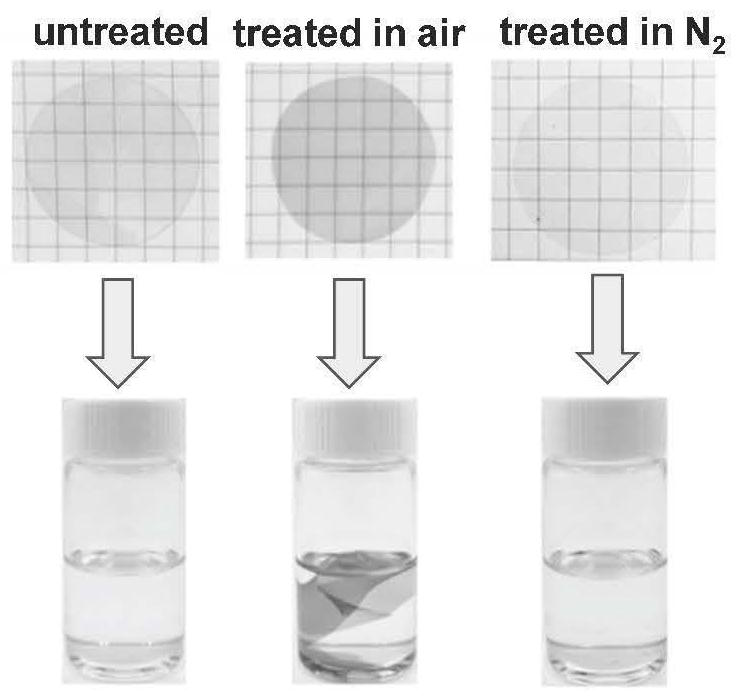

[0047] The benzyl polyimide synthesis method and film preparation method are the same as in Example 1, except that the temperature of thermal oxygen treatment is 300° C. for 5 hours. Among them, the hydrogen permeability coefficient of this type of membrane can reach 330 Barrer, the hydrogen methane separation selectivity coefficient can reach 85, the carbon dioxide permeability coefficient can reach 200 Barrer, and the carbon dioxide methane selectivity coefficient can reach 50.

Embodiment 3

[0049] The benzyl polyimide synthesis method and film preparation method are the same as in Example 1, except that the temperature of thermal oxygen treatment is 300° C. for 10 h. Among them, the hydrogen permeability coefficient of this type of membrane can reach 330 Barrer, the hydrogen methane separation selectivity coefficient can reach 85, the carbon dioxide permeability coefficient can reach 200 Barrer, and the carbon dioxide methane selectivity coefficient can reach 50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com