Low-cost recycling process of carbide slag in acetylene production

A low-cost technology of carbide slag, which is applied in the field of low-cost recycling technology of carbide slag in the production of acetylene, can solve the problems that the strong alkalinity treatment ability of carbide slag needs to be tapped and utilized, and achieves the convenience of recycling waste, reducing acidity, and strong activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

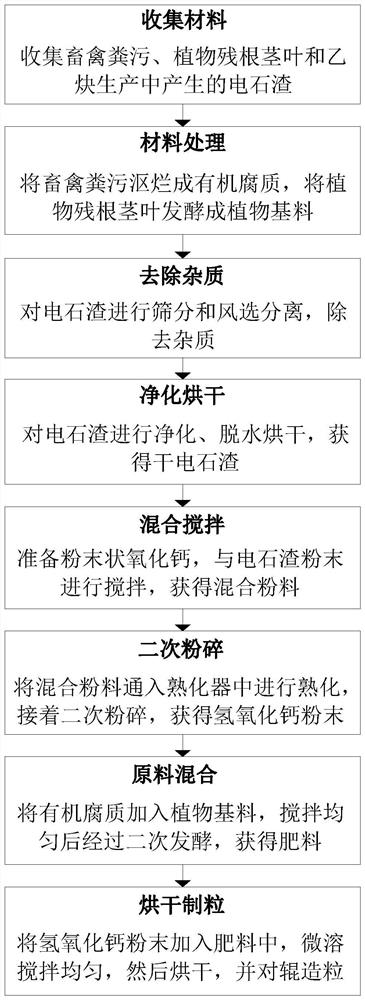

[0029] according to figure 1 As shown, this embodiment proposes a low-cost recycling process for carbide slag in the production of acetylene, including the following steps:

[0030] Step 1: collect materials, collect livestock and poultry manure and plant stumps, stems and leaves, collect carbide slag produced in acetylene production, and keep it for later use;

[0031] Step 2: material treatment, sealing and retting livestock and poultry manure into organic humus, and anaerobically fermenting plant residues, stems and leaves into plant base materials, which are reserved for later use;

[0032] Step 3: remove impurities, carry out sieving and winnowing separation to the calcium carbide slag, and remove impurities;

[0033] Step 4: purifying and drying, purifying, dehydrating and drying the carbide slag to obtain dry carbide slag;

[0034] Step 5: mixing and stirring, discharging the dry calcium carbide slag into a pulverizer, pulverizing it into powder, then preparing powder...

Embodiment 2

[0040] This embodiment proposes a low-cost recycling process for carbide slag in the production of acetylene, including the following steps:

[0041] After collecting the livestock and poultry manure, heat the livestock and poultry manure and crush and stir it. After collecting the residual plant roots, stems and leaves, pulverize them to a length of 2-3 cm, use a baler to perform high-density compaction and baling, and collect calcium carbide Slag, choose carbide slag without any treatment.

[0042] Livestock and poultry manure is sealed and retting for 7-10 days to obtain organic decay. During this process, the temperature is controlled at 40-50°C, ammonium bicarbonate is added, and the residual roots, stems and leaves of plants are sealed and stacked, and anaerobic fermentation is carried out for 20- 30 days, and the temperature is controlled at 15-25°C.

[0043] Before removing impurities, collect industrial waste slag fly ash in power plants, add fly ash to carbide slag ...

Embodiment 3

[0054] This embodiment proposes a low-cost recycling process for carbide slag in the production of acetylene, wherein, in the secondary fermentation process, silicate bacteria, actinomycetes, nitrogen-fixing bacteria, mycorrhizal fungi, Bacillus subtilis, polymyxa Paenibacillus, Trichoderma and Streptococcus thermophilus were used as fermentation bacteria, and trace elements of manganese and boron were added.

[0055] The invention thus promotes fermentation and increases fertilizer nutrition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com