Nickel-rich high-voltage sodium ion battery positive electrode material as well as preparation method and application thereof

A cathode material, sodium ion technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low energy density and poor cycle performance, and achieve the effects of low reaction temperature, good heat dissipation characteristics, and enhanced structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

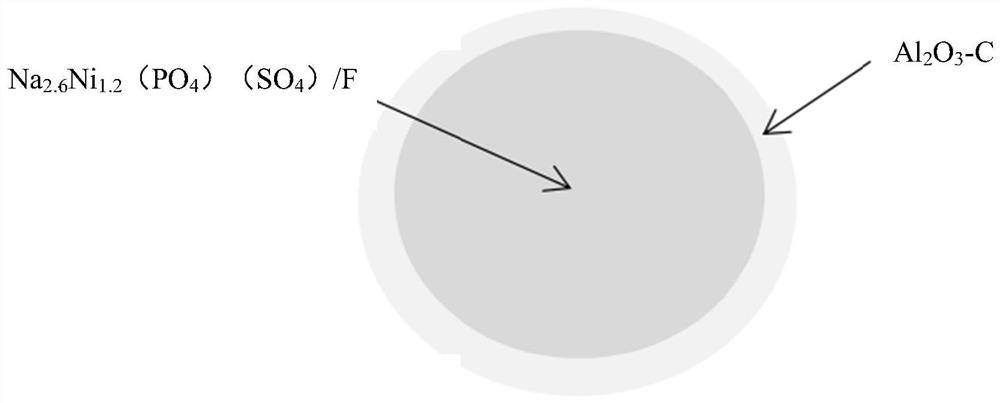

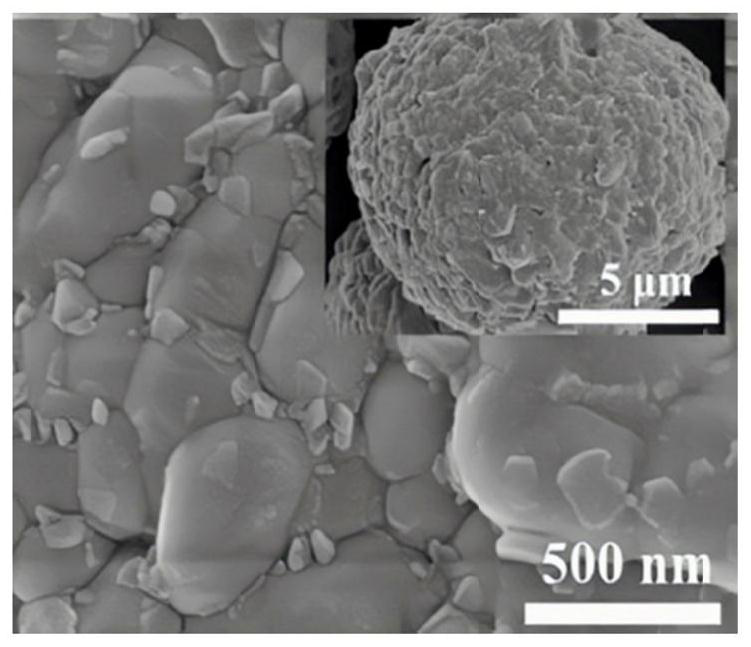

[0046] The sodium ion cathode material of the present embodiment, its formula is Na 2.6 Ni 1.2 (PO 4 )(SO 4 ) / F@Al 2 o 3 -C.

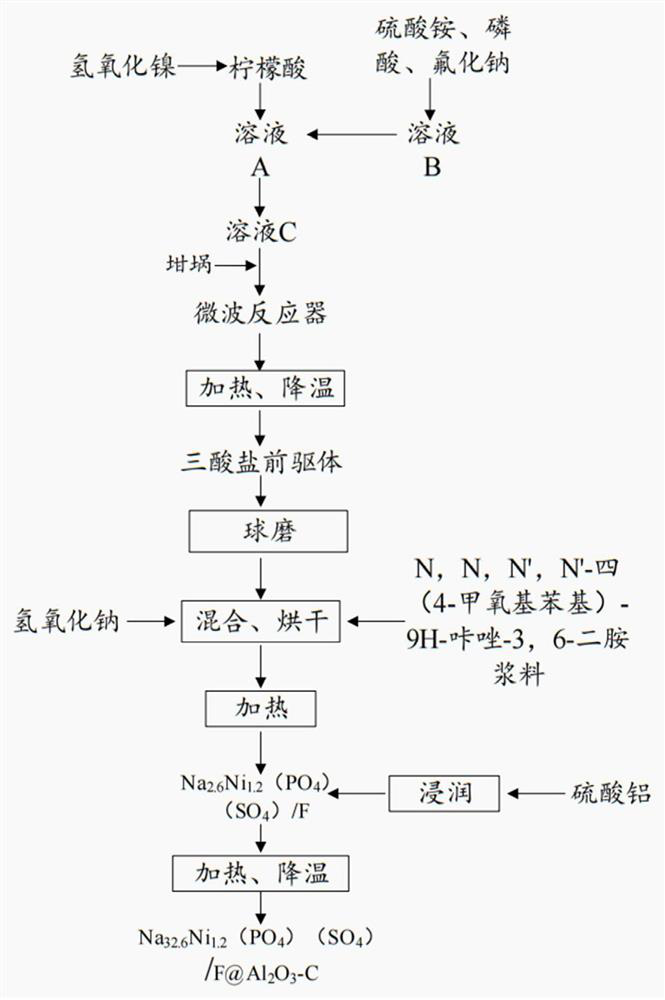

[0047] The process flow diagram of the sodium ion cathode material prepared in this embodiment is as follows figure 1 as shown, figure 1 In the process, nickel hydroxide was mixed with citric acid to obtain solution A, ammonium sulfate, phosphoric acid and ammonium fluoride were mixed to obtain solution B, stirred, solution B was added to solution A to obtain solution C, solution C was placed in a ceramic crucible, and sent to A microwave reactor is heated and cooled to obtain a trisalt precursor. After ball milling the trisalt precursor, mix it with sodium hydroxide, N,N,N',N'-tetrakis(4-methoxyphenyl)-9H-carbazole-3,6-diamine slurry Uniform, heated to get Na 2.6 Ni 1.2 (PO 4 )(SO 4 ) / F. Aluminum Sulfate and Na 2.6 Ni 1.2 (PO 4 )(SO 4 ) / F infiltration, heating, and cooling to get Na 2.6 Ni 1.2 (PO 4 )(SO 4 ) / F@Al 2 o 3 -C.

[0...

Embodiment 2

[0053] The sodium ion cathode material of the present embodiment, its formula is Na 3.4 Ni 0.8 (PO 4 )(SO 4 ) / F@CuO-C.

[0054] The preparation method of the sodium ion positive electrode material of the present embodiment, concrete steps are as follows:

[0055] (1) Microwave hydrothermal synthesis of tri-salt precursor: 1.24g of nickel sulfate was dissolved in 150mL of 7.1w% oxalic acid to obtain solution A, 19mL of 0.53mol / L ammonium sulfate, 1.33g of diammonium hydrogen phosphate, 12mL of 0.18mol / L Ammonium fluoride was mixed to obtain solution B, stirred, solution B was gradually added dropwise to solution A to obtain solution C, 20mL solution C was taken, solution C was placed in a ceramic crucible, and sent to a microwave reactor, which was filled with argon, Under 500W, set: the heating temperature of the first stage is 115°C, and it is stable for 3 minutes; the heating temperature of the second stage is 240°C, and it is stable for 20 minutes;

[0056] (2) Synthes...

Embodiment 3

[0059] The sodium ion cathode material of the present embodiment, its formula is Na 3 Ni(PO 4 )(SO 4 ) / F@ZnO-C.

[0060] The preparation method of the sodium ion positive electrode material of the present embodiment, concrete steps are as follows:

[0061] (1) Microwave hydrothermal synthesis of trisalt precursor: 1.3g nickel chloride was dissolved in 500mL0.317mol / Lw% citric acid to obtain solution A, 19mL0.53mol / L ammonium sulfate, 1.33g diammonium hydrogen phosphate, 17mL0 .18mol / L ammonium fluoride was mixed to obtain solution B, stirred, solution B was gradually added dropwise to solution A to obtain solution C, 200mL solution C was taken, solution C was placed in a ceramic crucible, and sent to a microwave reactor. Filled with argon, under 350W, set: the first heating temperature is 115°C, steady evaporation for 3 minutes, the second heating temperature is 275°C, steady evaporation for 20 minutes, the heating time between the two stages is 180s, and the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com