Preparation method of copper sulfide electrode material and application of copper sulfide electrode material in extraction of copper from sewage

An electrode material, copper sulfide technology, applied in chemical instruments and methods, electrodes, separation methods, etc., can solve the problems of limited ion exchange capacity, poor removal ability at low concentration, and difficult treatment of residual chemicals, etc., to achieve short and fast preparation cycle The effect of adsorption rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 0.483g of copper nitrate trihydrate and 0.380g of thiourea were added to a mixed solution consisting of 10mL of ethylene glycol and 30mL of deionized water. After stirring to dissolve, add 0.05g of cetyltrimethylammonium bromide and continue stirring for 10min. Then the mixed solution was transferred into a reaction kettle, put into an oven, heated to 150° C., and reacted for 15 hours; after cooling to room temperature, the solid product was washed with absolute ethanol and deionized water. Finally put it into an oven and dry at 60° C. for 12 hours to obtain a copper sulfide electrode material.

Embodiment 1

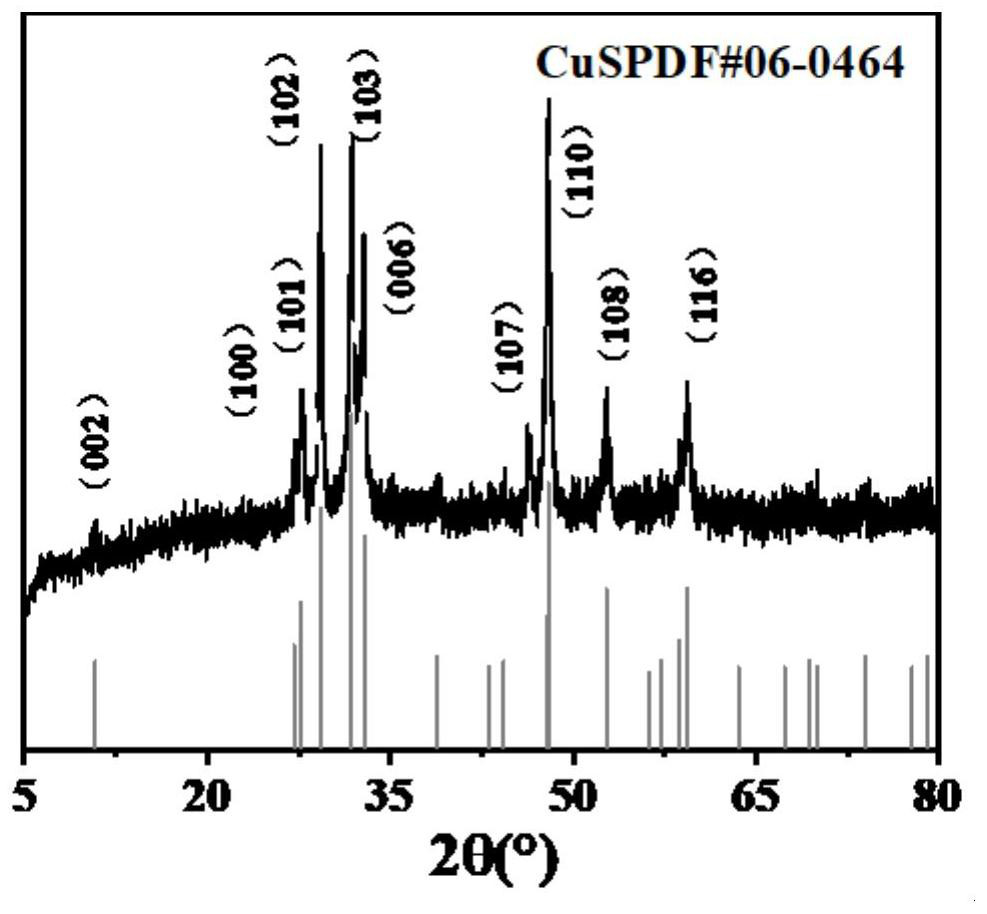

[0038] The X-ray diffraction spectrogram of the copper sulfide electrode material prepared in embodiment 1 is as figure 1 As shown, among them, the more obvious diffraction peaks are located at 2θ=10.81, 27.12, 27.68, 29.28, 31.78, 32.85, 47.78, 47.94, 52.71 and 59.35° respectively. Compared with copper sulfide crystal standard card PDF#06-0464, the above peaks correspond to (002), (100), (101), (102), (103), (006), (107) of copper sulfide crystal respectively ), (110), (108) and (116) crystal planes. In addition, there are no other impurity peaks in the X-ray diffraction spectrum. The above results show that the copper sulfide electrode material was successfully prepared in the experiment, and its crystallinity and purity are high.

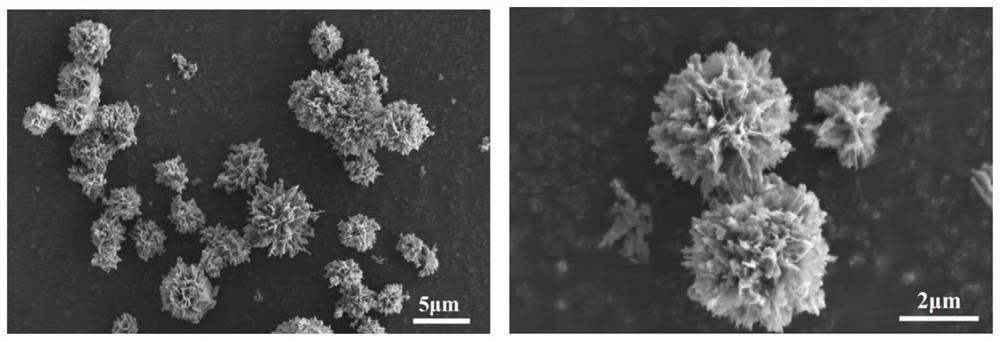

[0039] figure 2is the scanning electron microscope and elemental distribution map of the prepared copper sulfide material. It can be seen from the figure that the prepared copper sulfide is a microsphere with a size of 3-5 microns. In the e...

Embodiment 2

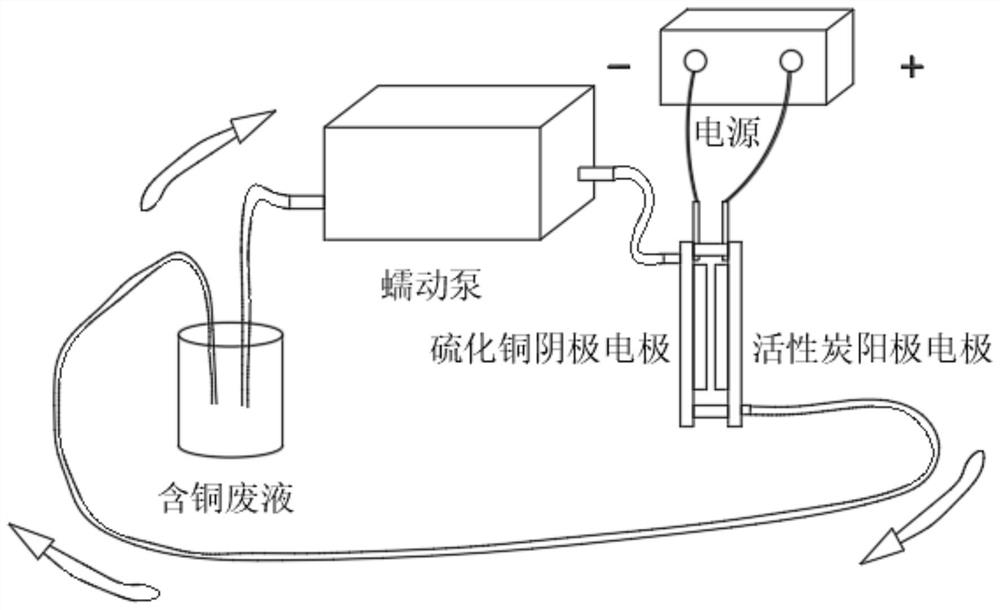

[0043] The obtained copper sulfide electrode material is used as an active material, mixed uniformly with conductive carbon black at a mass ratio of 8:1, added absolute ethanol, after stirring evenly, the binder added, the ratio of the active material to the binder is 8 :1, Stir well. Subsequently, the resulting mixture was coated on graphite paper with a film thickness of 100-600 μm. The coated graphite paper was dried at 50° C. for 10 h to obtain a cathode electrode for capacitive deionization whose active material was copper sulfide. also, image 3 is a schematic diagram of a capacitive deionization device. Figure 4 It is a schematic diagram of the assembly method of the asymmetric capacitive deionization module, where a is the current collector, b is the titanium strip, c is the copper sulfide cathode electrode, d is the non-woven fabric, e is the silica gel gasket, and c’ is the activated carbon anode electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com