Absorbable polyurethane elastomer with high flexibility, high elasticity and controllable degradation as well as preparation method and application of absorbable polyurethane elastomer

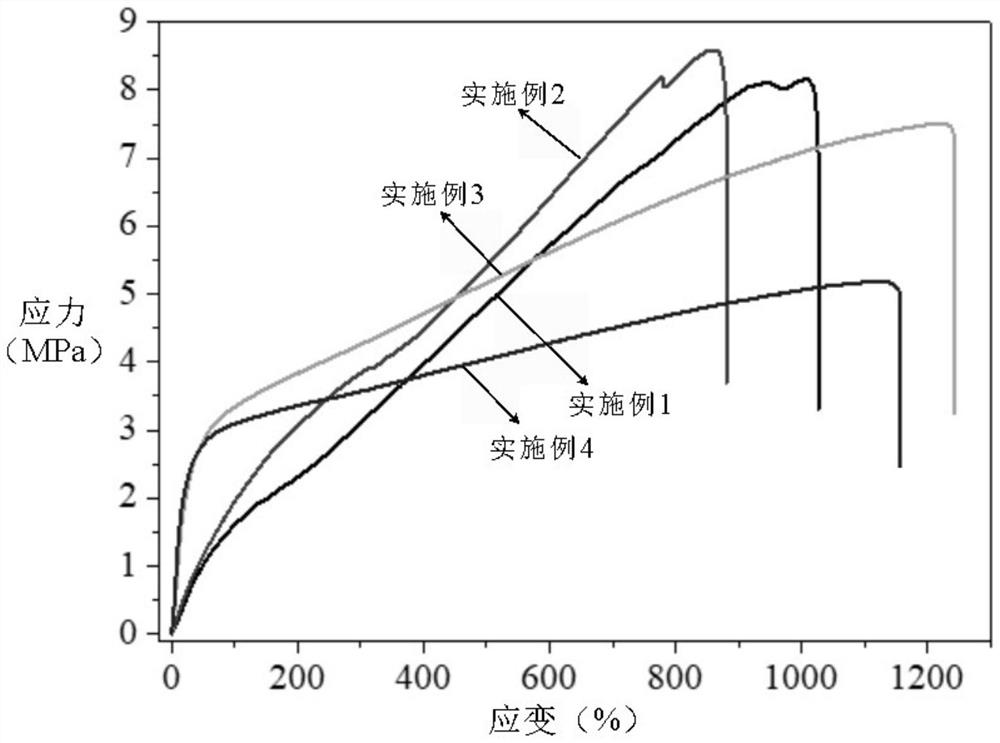

A polyurethane elastomer, high elasticity technology, applied in prosthesis, medical formula, surgery, etc., can solve the problems of ineffective adjustment of degradation rate, long residence time, complex environment, etc., achieve controllable adjustment of degradation time, increase strength and Excellent toughness and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

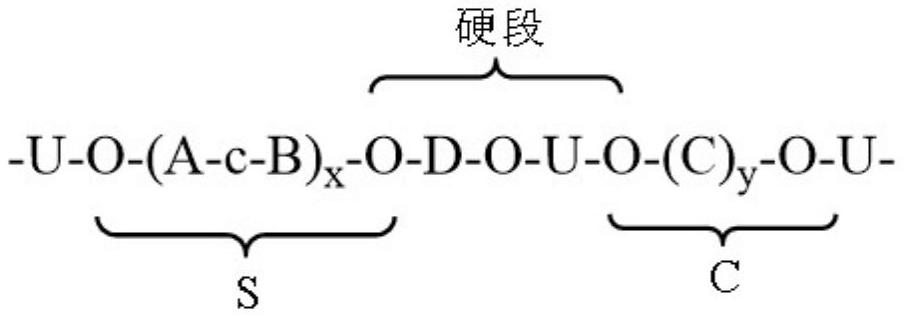

[0035] A preparation method of a highly flexible, highly elastic, degradable and adjustable absorbable polyurethane elastomer, comprising the following steps:

[0036] Step 1: Add aliphatic random copolyester diol prepolymer and aliphatic polyester diol prepolymer into the reactor, remove water and dry under constant temperature and vacuum conditions; use an oil bath to keep the temperature constant , the water removal temperature is 30~60℃; the vacuum degree is kept at 0.06~0.12MPa; the water removal time is usually 3~8h. After the water removal is complete, the temperature is raised to above the melting point of the prepolymer under a protective atmosphere to melt and mix. The protective atmosphere is an inert gas, which can be high-purity nitrogen or helium.

[0037] Step 2: under a protective atmosphere, diisocyanate is added to the mixture obtained in step 1, and after sufficient reaction, an isocyanate-terminated prepolymer is obtained, and the reaction time is 1-3 hour...

Embodiment 1

[0047] A preparation method of a highly flexible, highly elastic, degradable and adjustable absorbable polyurethane elastomer, comprising the following steps:

[0048] Step 1: The aliphatic random copolyester diol prepolymer (HO-P(DO-c-δVL) with a number average molecular weight of 10.0kg / mol 50% )-OH) and polycaprolactone prepolymer (HO-PCL-OH) with a number-average molecular weight of 1.4 kg / mol were added to the reactor at a mass ratio of 5:1, and dehydrated in an oil bath at 60 °C for 5 h under vacuum. Keep at 100Pa, after water removal, under nitrogen protection, melt and mix the prepolymer in an oil bath at 80°C;

[0049] Step 2: Under nitrogen protection, add 1,6-hexamethylene diisocyanate with a molar amount of terminal hydroxyl groups of 1.85 / 1 to the mixture obtained in step 1, and react in an oil bath at 80 °C for 3 hours to obtain an isocyanate-terminated pre-polymer. polymer.

[0050] Step 3: Under nitrogen protection, add the chain extender 1,4-butanediol with ...

Embodiment 2

[0052] A preparation method of a highly flexible, highly elastic, degradable and adjustable absorbable polyurethane elastomer, comprising the following steps:

[0053] Step 1: The aliphatic random copolyester diol prepolymer (HO-P(DO-c-δVL) with a number average molecular weight of 1.0kg / mol 42% )-OH) and polyvalerolactone prepolymer (HO-PVL-OH) with a number-average molecular weight of 1.4 kg / mol were added to the reactor at a mass ratio of 1:10, and dehydrated in an oil bath at 60 °C for 5 h under vacuum. Keep at 100Pa, after water removal, under nitrogen protection, melt and mix the prepolymer in an oil bath at 80°C;

[0054] Step 2: Under nitrogen protection, add L-lysine diisocyanate with a molar amount of terminal hydroxyl groups of 4 / 1 to the mixture obtained in step 1. The isocyanate-terminated prepolymer was obtained after 3 h of reaction in an oil bath at 80°C.

[0055] Step 3: Under nitrogen protection, add chain extender 1,7-heptanediol with 3 / 1 molar amount of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com