Breathable easy-to-tear heat-seal coating adhesive capable of being heat-sealed on various base materials

A glue coating and base material technology, which is applied in the field of sterilization packaging of medicine and medical devices, can solve problems such as thermal creep, and achieve the effects of good thermal creep resistance, good aging resistance, and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

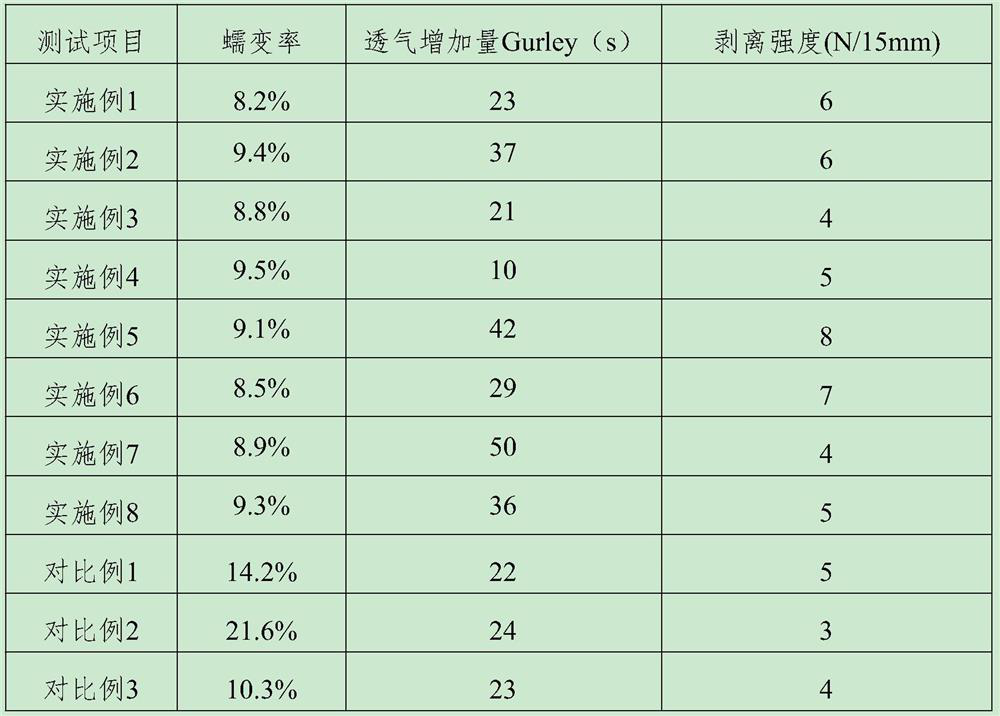

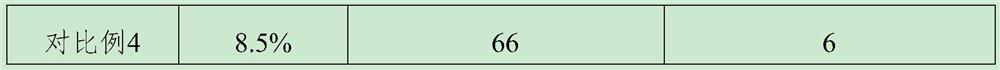

Examples

Embodiment 1

[0017] An easy-to-release heat-sealing glue that is breathable and can be heat-sealed on a variety of substrates, characterized in that the heat-sealing glue comprises the following components by weight: 15 parts of acrylate copolymer, 15 parts of maleic anhydride 12 parts of branched polyethylene resin, 8 parts of modified epoxy resin, the modified epoxy resin is p-hydroxybenzoic acid epoxy resin, Tg point is 70°C, solid content is 35%, 1,6-hexamethylene diisocyanate 5 parts, 1 part of dodecyl fatty acid polyoxyethylene ether, 4 parts of polybutene, 0.5 part of dimethylaminopropylamine binder, 50 parts of isopropyl acetate solvent, 0.1 part of nano titanium dioxide UV remover, 2- 0.5 part of methylpropanesulfonic acid formulation, 0.1 part of polymeric urea smoothing agent, 0.1 part of antioxidant 168, 0.5 part of diisononyl phthalate excipient, and 0.2 part of dimethicone defoaming agent.

Embodiment 2

[0019] An easy-to-release heat-sealing glue that is breathable and can be heat-sealed on a variety of substrates, characterized in that the heat-sealing glue comprises the following components by weight: 30 parts of acrylate copolymers, 30 parts of maleic anhydride 35 parts of branched polyethylene resin, 19 parts of modified epoxy resin, the modified epoxy resin is p-hydroxybenzoic acid epoxy resin, Tg point is 80°C, solid content is 45%, 1,6-hexamethylene diisocyanate 10 parts, 6 parts of dodecyl fatty acid polyoxyethylene ether, 8 parts of polybutene, 1.5 parts of m-phenylenediamine binder, 85 parts of methyl ethyl ketone solvent, 2-hydroxy-4-methoxybenzophenone 0.3 parts of UV remover, 1.2 parts of hydroxypropyl acrylate formulation, 0.5 parts of polyethylene wax smoothing agent, 0.2 parts of antioxidant 1076, 4 parts of zinc ethylphenyl dithiocarbamate excipient, cyanuric chloride melamine 0.6 part of defoaming agent.

Embodiment 3

[0021] An easy-to-release heat-sealing glue that is breathable and can be heat-sealed on a variety of substrates, characterized in that the heat-sealing glue comprises the following components by weight: 30 parts of acrylate copolymers, 30 parts of maleic anhydride 12 parts of branched polyethylene resin, 19 parts of modified epoxy resin, the modified epoxy resin is p-hydroxybenzoic acid epoxy resin, Tg point is 70°C, solid content is 45%, 1,6-hexamethylene diisocyanate 5 parts, 6 parts of dodecyl fatty acid polyoxyethylene ether, 4 parts of polybutene, 1.5 parts of diaminodiphenylmethane binder, 50 parts of isopropyl alcohol solvent, hexamethylphosphoric triamide UV remover 0.3 part, 0.5 part of sodium propylene sulfonate formulation, 0.5 part of polyamide wax smoothing agent, 0.1 part of antioxidant 164, 4 parts of didecyl phthalate excipient, 0.2 part of polyoxypropylene glyceryl ether defoamer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com