Phase transfer process and system for preparing silicon nitride powder in batches by gas-phase chemical plasma method

A silicon nitride powder and powder technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high carbon content, affecting the performance of silicon nitride ceramics, and low purity of powder materials, and achieve The effect of improving powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

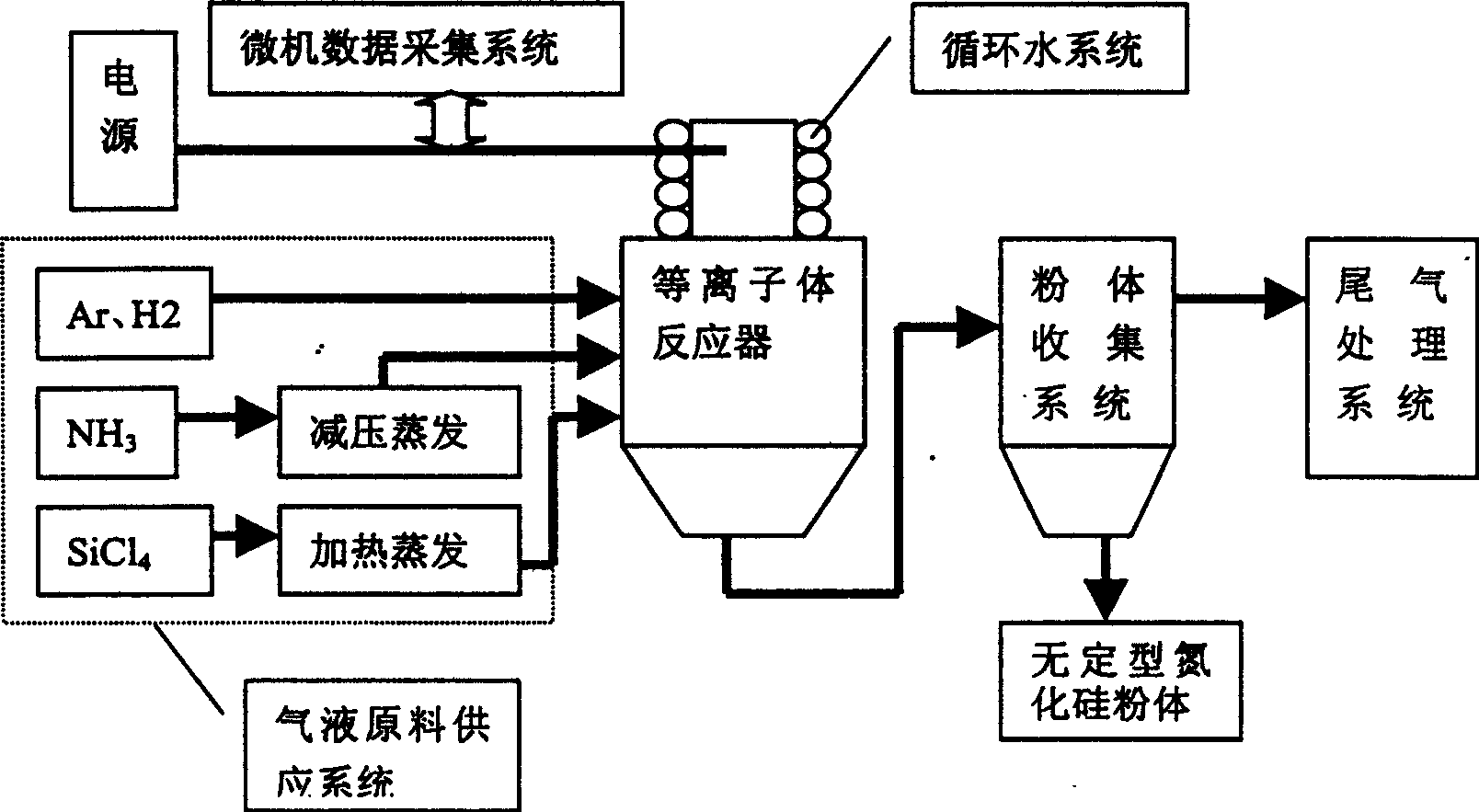

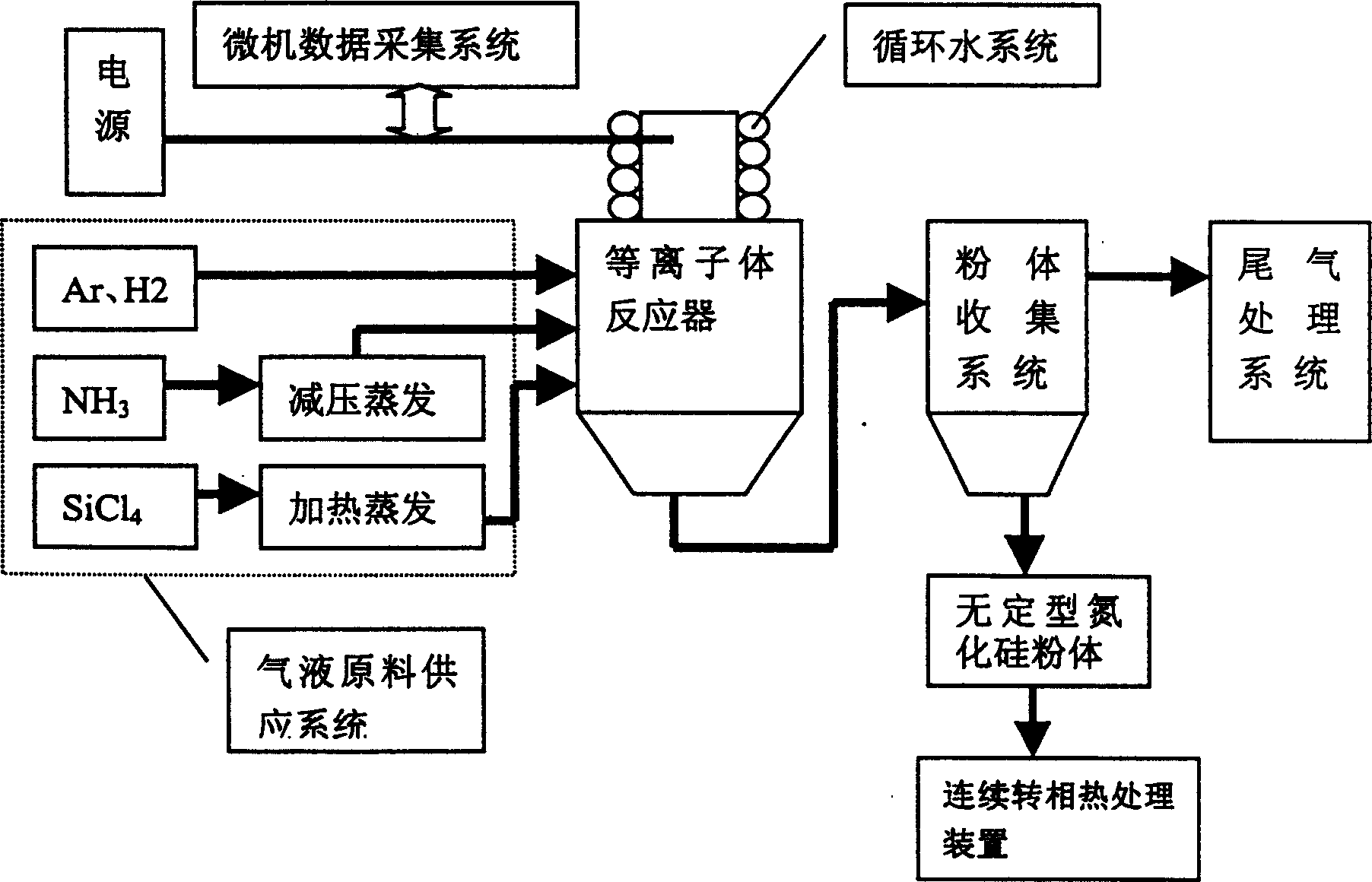

[0020] figure 1 It is a process flow chart of preparing amorphous silicon nitride powder by plasma chemical vapor phase method. First, the plasma working gases Ar and H are introduced 2 , and then start the plasma power supply, the plasma generator generates a plasma arc, and the gas flowing through the arc is heated to a high temperature of about 5000°C and enters the reactor; at the same time, the NH 3 and SiCl 4 Raw gas also enters the plasma reactor, rapid decomposition and Si 3 N 4 synthesis reaction.

[0021]

[0022] Generated Si 3 N 4 After crystallization and growth in a very short time (milliseconds), it is then transported through pipelines to a cold environment for rapid cooling, and then through a powder collection system to achieve gas-solid separation to obtain amorphous Si 3 N 4 Powder; the separated gas is discharged into the atmosphere after being treated by the tail gas treatment system.

[0023] The surface obtained by the above process is c...

Embodiment 1

[0026] Use plasma chemical vapor reaction equipment to first obtain amorphous silicon nitride powder; then through the above-mentioned continuous phase inversion heat treatment system, the atmosphere in the furnace is NH 3 :N 2 =1:1 under the condition of mixed gas, after about 1.5 hours of treatment at 600 ° C, the ammonium chloride crystals on the surface of the amorphous silicon nitride powder were removed; High-purity, ultra-fine, high-performance silicon nitride powder with high α-phase content. The performance index of the powder is as follows:

[0027] Test items

Si(%)

N(%)

O(%)

Test results

59

38.5

1.28

[0028] Fluorescent X-ray analysis has been used to detect residual chlorine.

[0029] 2. Phase composition:

[0030] Using the X-ray diffraction analysis method, the α-phase and β-phase contents of the produced silicon nitride powder are calculated as follows:

[0031] α phase: 97.5% β phase: 2.5%

[0032] 3. Pa...

Embodiment 2

[0035] Use plasma chemical vapor reaction equipment to first obtain amorphous silicon nitride powder; then through the above-mentioned continuous phase inversion heat treatment system, the atmosphere in the furnace is NH 3Under the condition of 500°C for about 2 hours, the ammonium chloride crystals on the surface of the amorphous silicon nitride powder were removed; and then heat treated at 1500-1550°C for about 1.5 hours to obtain high-purity, high α-phase content high performance silicon nitride powder. The performance index of the powder is as follows:

[0036] Test items

Si(%)

N(%)

O(%)

Test results

61.7

37.3

0.1

[0037] Fluorescent X-ray analysis has been used to detect residual chlorine.

[0038] 2. Phase composition:

[0039] Using the X-ray diffraction analysis method, the α-phase and β-phase contents of the produced silicon nitride powder are calculated as follows:

[0040] α phase: 95.5% β phase: 4.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com