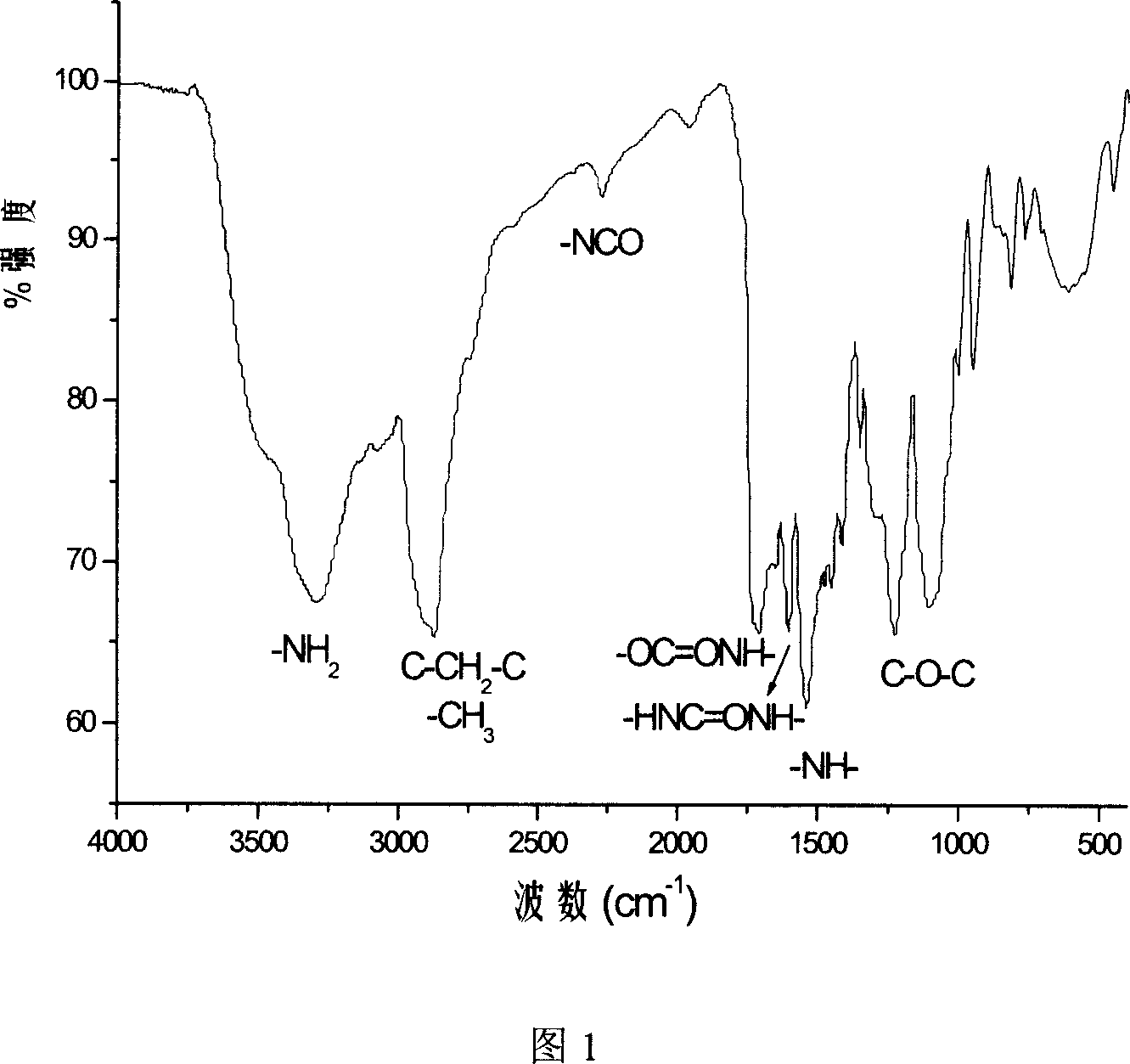

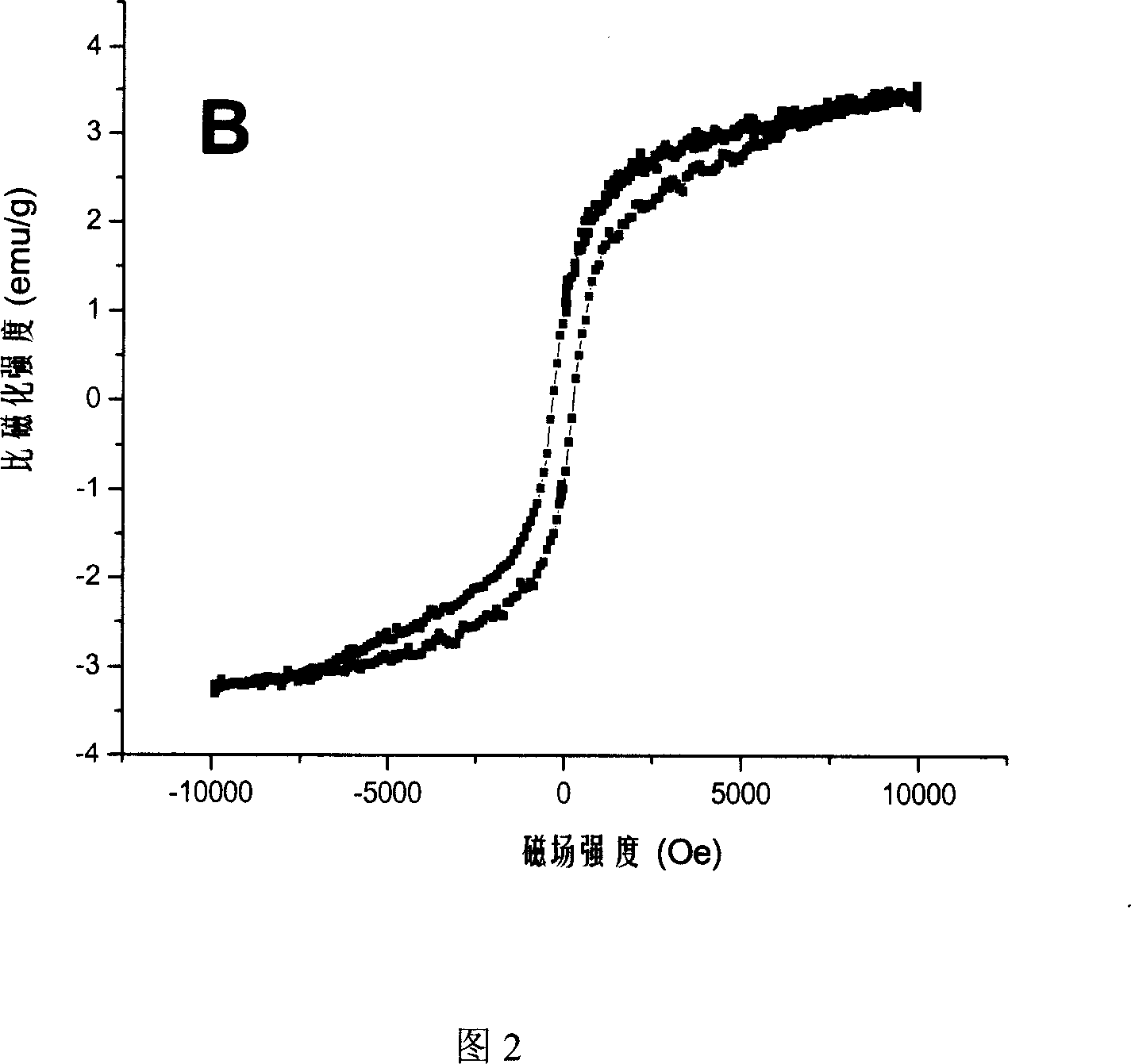

Core/shell type polyurethane magnetic compound microsphere, preparation method and use thereof

A magnetic composite microsphere and polyurethane technology, applied in biochemical equipment and methods, microorganisms, pharmaceutical formulations, etc., can solve the problems of difficult control of magnetic properties and weak magnetic response of microspheres, and achieve low production cost and stable suspension performance good, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

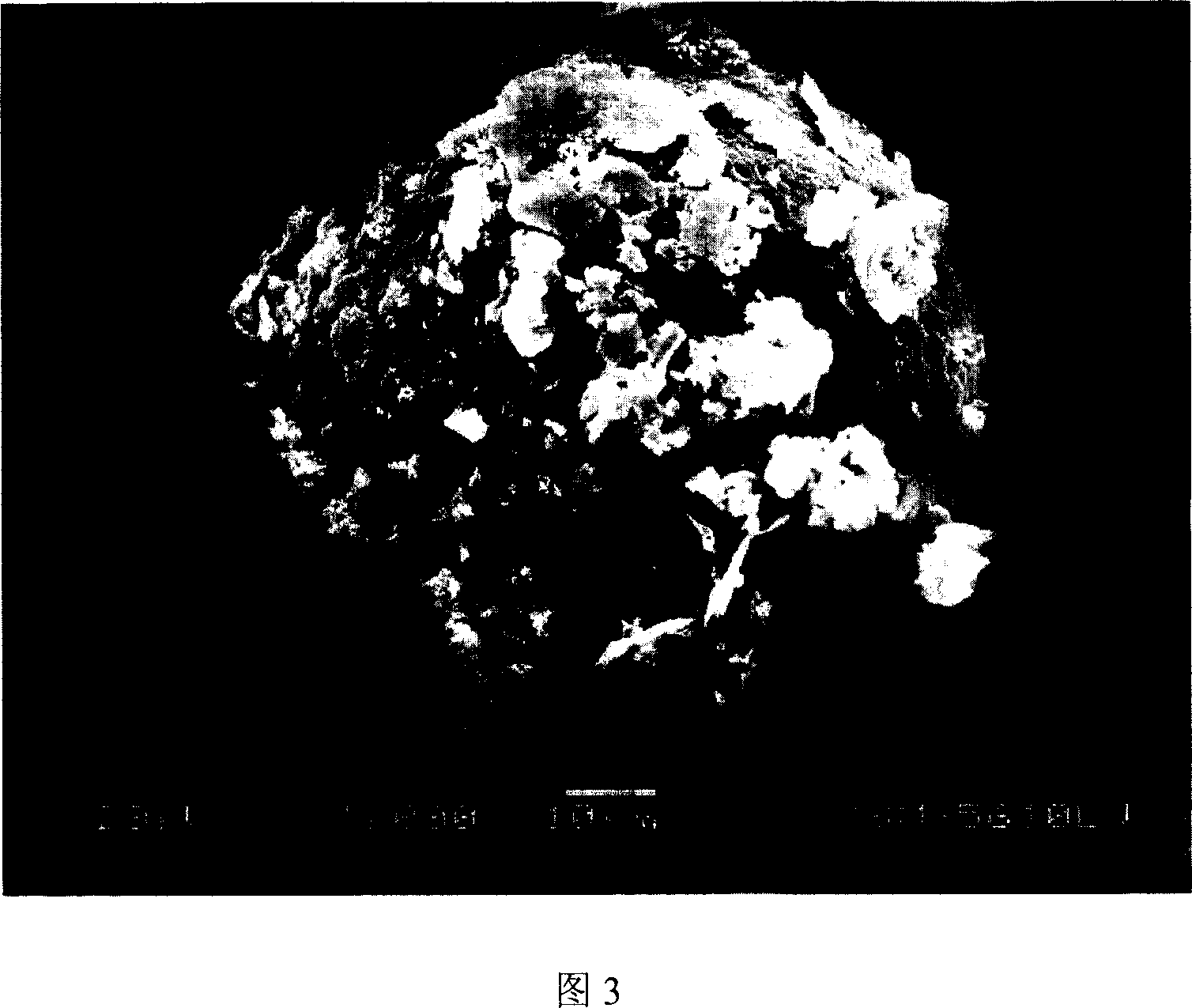

[0037] Weigh 2 grams of BaFe 12 o 19 The powder was added to a mixed solution containing 200 ml of distilled water and 200 ml of absolute ethanol, and 4.8 ml of N-β-aminopropyltrimethoxysilane (HC-792) was added dropwise to the solution for ultrasonic dispersion for 10 minutes. Dry the three-necked flask with a condenser tube and a mechanical stirrer, heat it to 70°C with closed stirring, react at a constant temperature for 5 hours, let it stand for washing with water, separate the solid from the liquid, dry it in a constant temperature blast drying oven at 80°C for 5 hours, and grind it to obtain a modified Sexual BaFe 12 o 19 Powder ready for use.

[0038] Weigh 1 gram of modified BaFe 12 o 19The powder was added to a dry vial with 70 milliliters of xylene and ultrasonically dispersed for 10 minutes, 5 milliliters of toluene diisocyanate was added dropwise, and sealed and stirred at room temperature for 50 minutes, after adding 10 grams of PEG and 1.5 milliliters of tol...

Embodiment 2

[0040] Weigh 1 gram of modified BaFe 12 o 19 Powder, add to a dry vial containing 70 ml of xylene and ultrasonically disperse for 10 minutes, add 5 ml of toluene diisocyanate dropwise, seal and stir at room temperature for 50 minutes, add 10 grams of polyethylene glycol 1000, 1.5 ml of toluene diisocyanate and stir for 120 minutes Finally, the xylene solution of the prepolymer is dropped into the three-necked flask containing 1% (mass / volume) polyvinylpyrrolidone and 300 milliliters of aqueous solution of a few drops of triethanolamine, and 1.5 milliliters of chain extender glycerol is added. Heat to 70° C. with sealing and stirring, react at constant temperature for 5 hours, wash the obtained product 4 to 5 times, magnetically separate, soak in 50% (volume) ethanol solution for 12 hours, and dry to obtain brown microspheres. The particle size of the microspheres is 200-300 microns.

Embodiment 3

[0042] Weigh 2 g Fe 3 o 4 The powder is added to a mixed solution containing 200 ml of distilled water and 200 ml of absolute ethanol, and 4.8 ml of N-β-aminopropyltrimethoxysilane is added dropwise to the solution for ultrasonic dispersion for 10 minutes. In a dry three-necked flask, close and stir and heat to 70°C, react at a constant temperature for 5 hours, stand still and wash with water, separate solid and liquid, dry in a constant temperature blast drying oven at 80°C for 5 hours, and grind to obtain modified Fe 3 o 4 Powder ready for use.

[0043] Weigh 1 gram of modified Fe 3 o 4 Powder, add to a dry vial containing 70 ml of xylene and ultrasonically disperse for 10 minutes, add 9.5 ml of diphenylmethane diisocyanate dropwise, add polyester polyol with a hydroxyl value of 55 ± 3 mg KOH / g, M = 2000 15 grams, sealed and stirred at room temperature for 180 minutes, the xylene solution of the prepolymer was dropped into a three-necked flask containing 1% (mass / volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com