Patents

Literature

32results about How to "Increased charring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

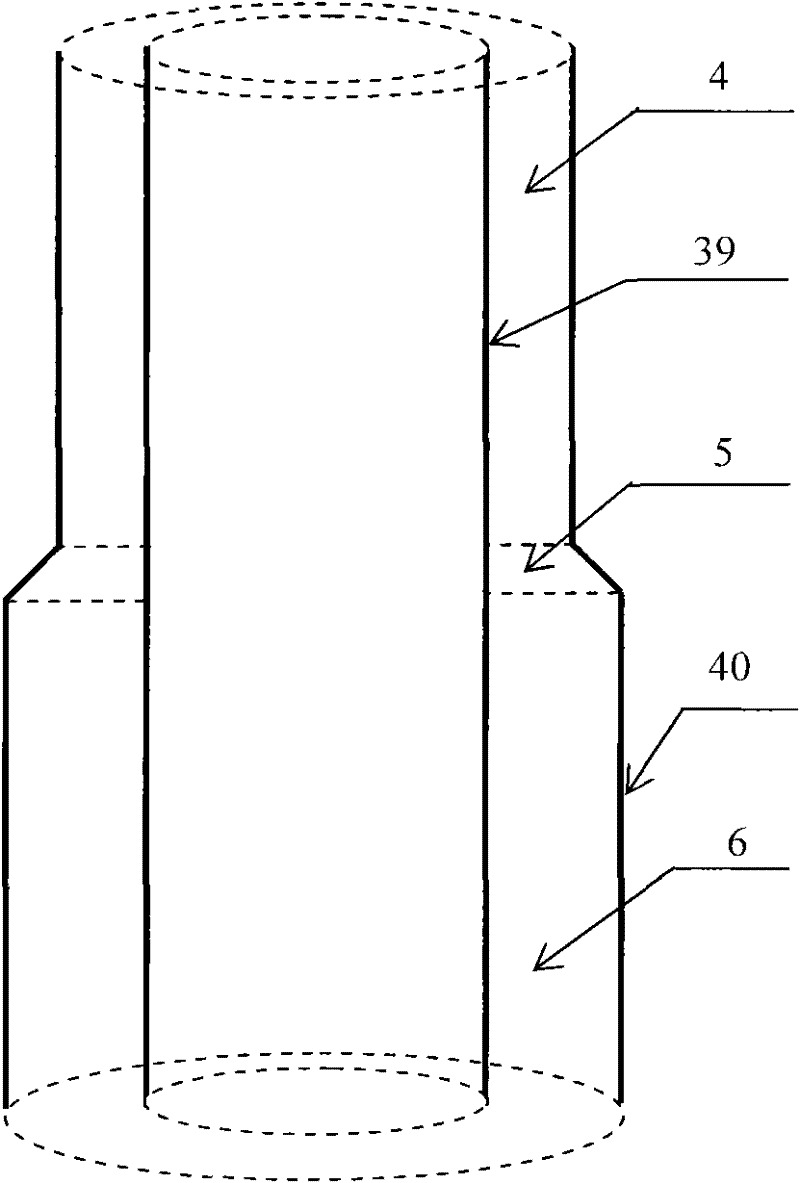

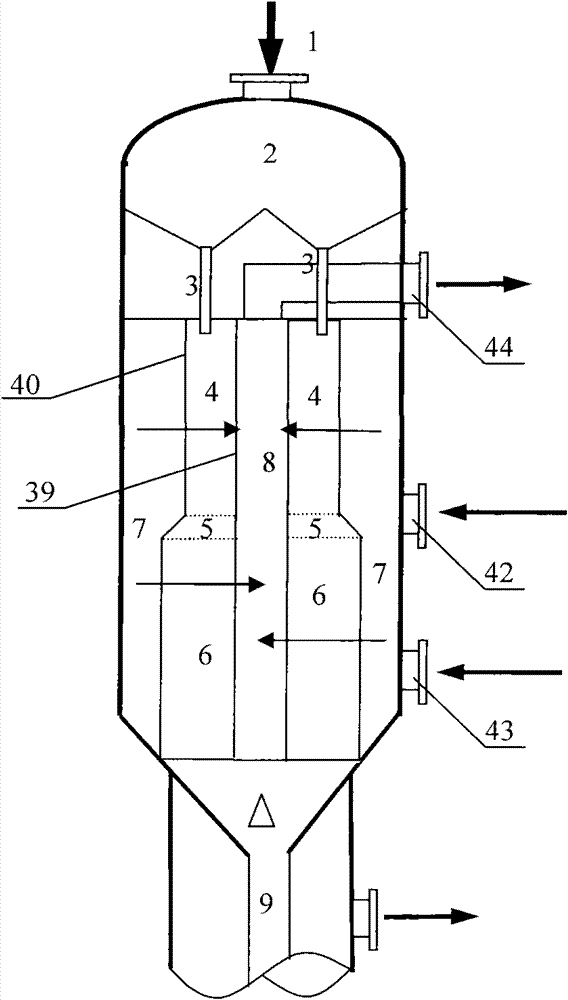

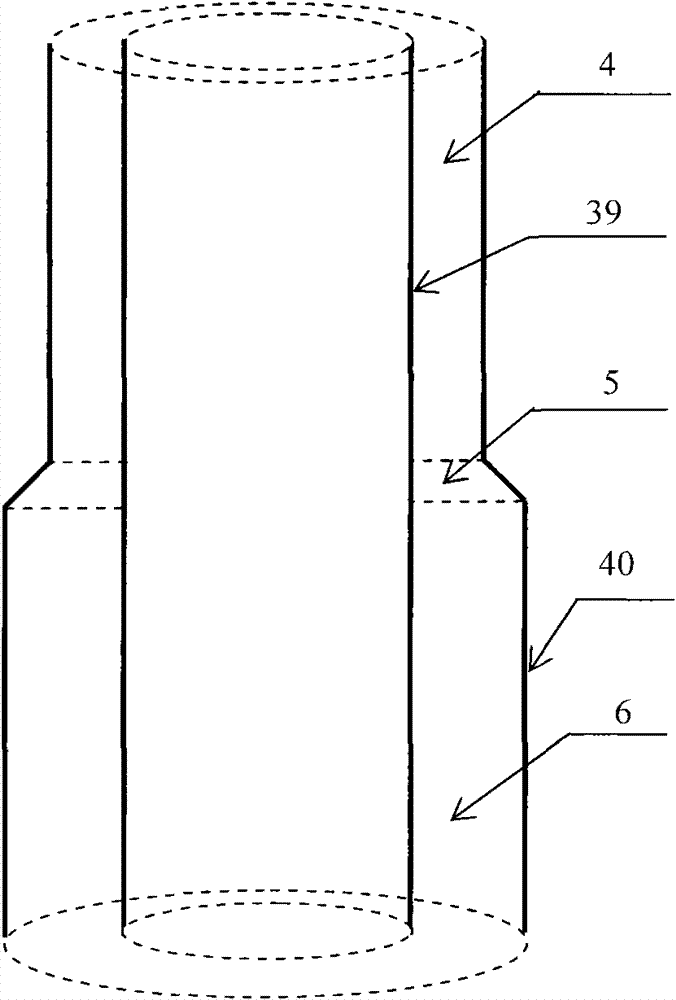

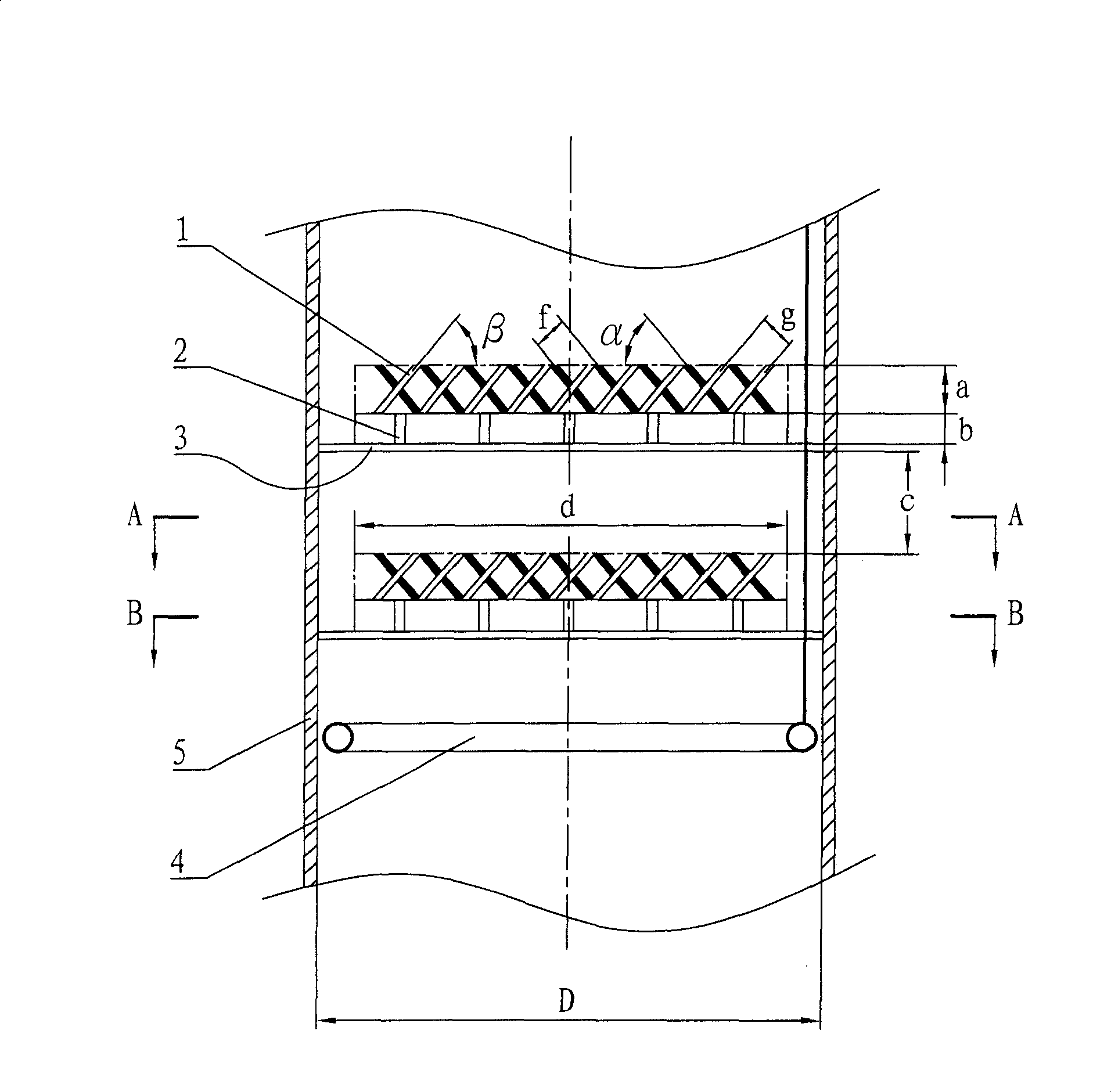

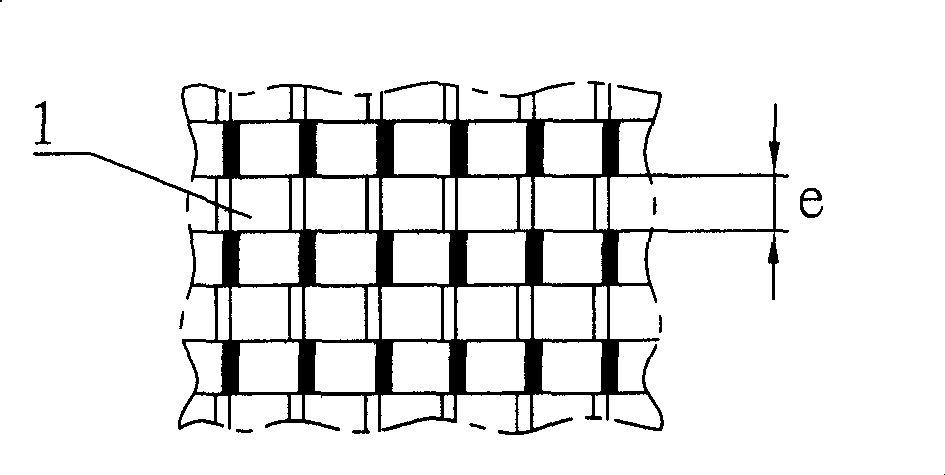

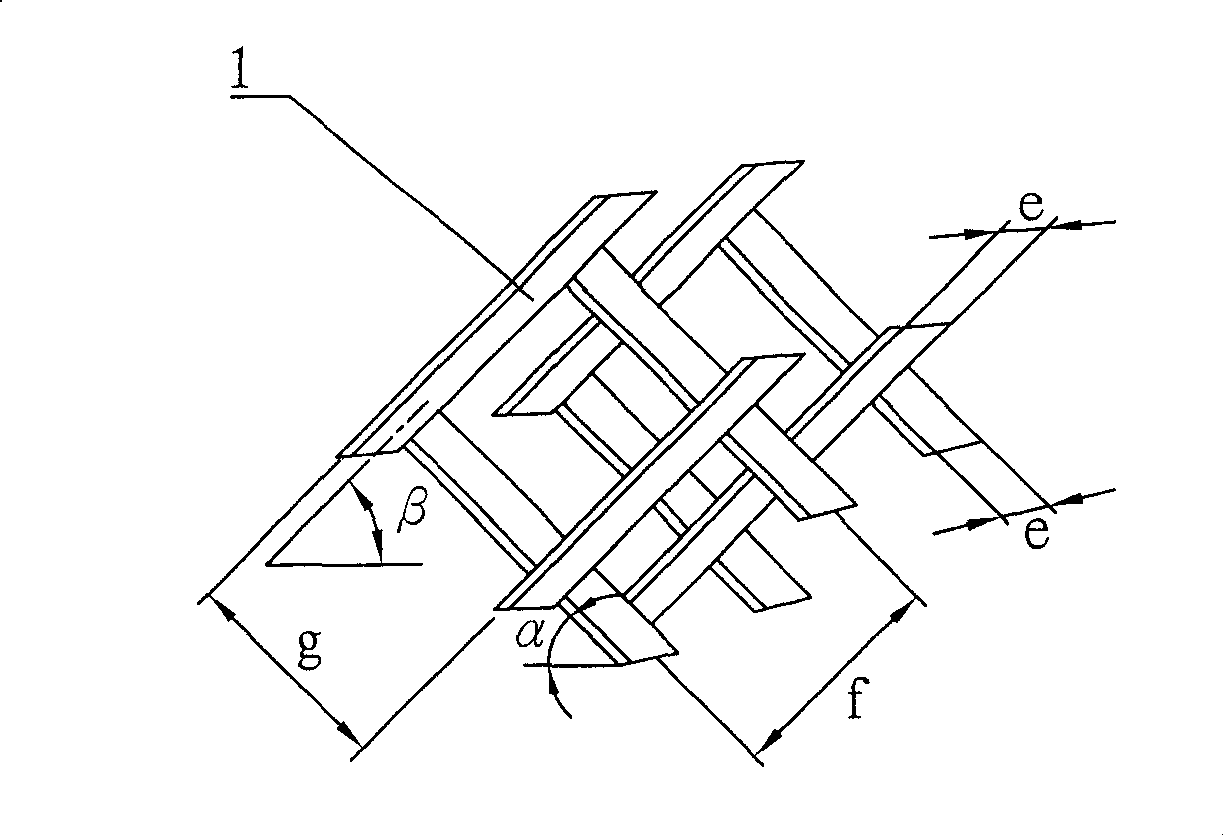

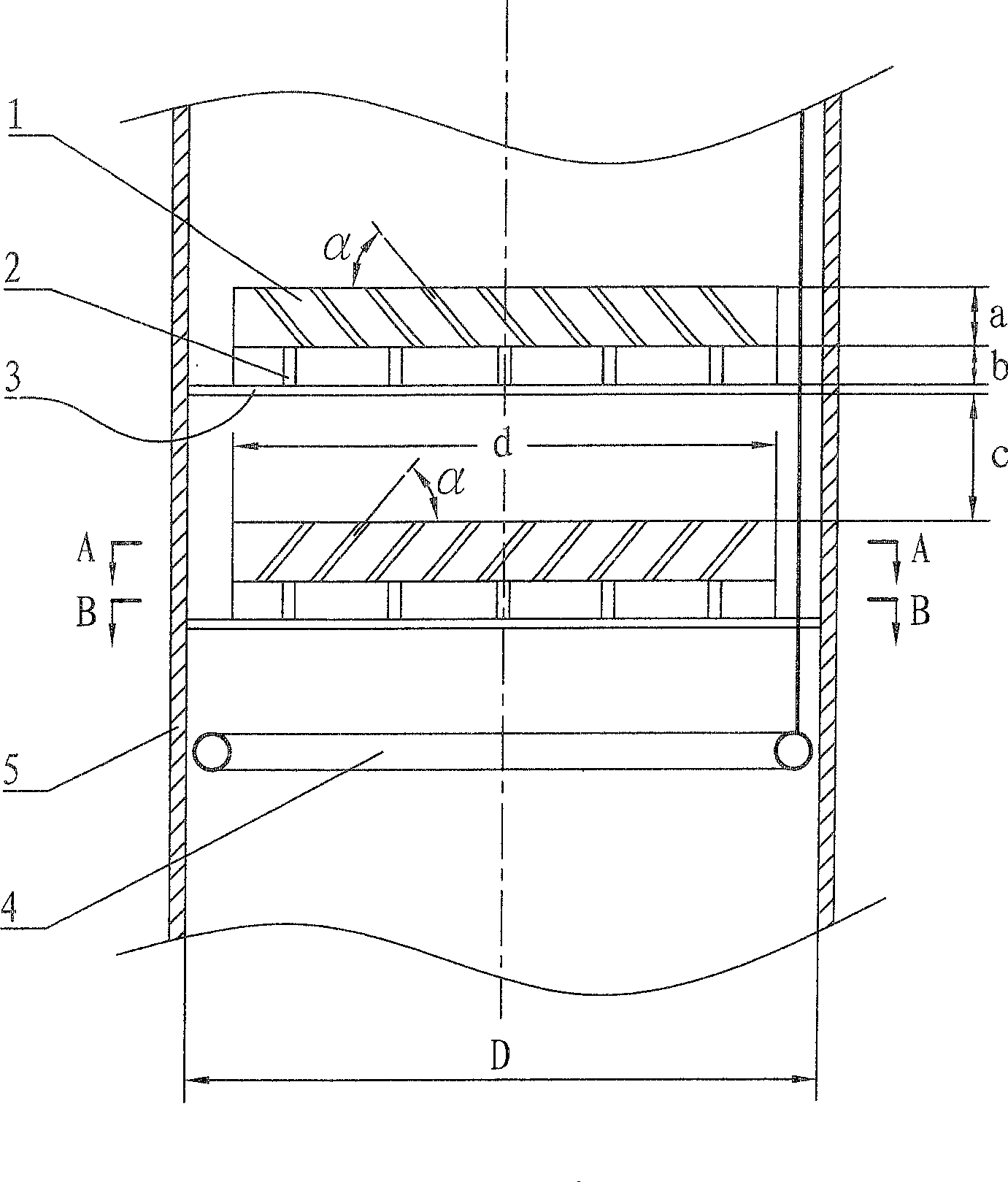

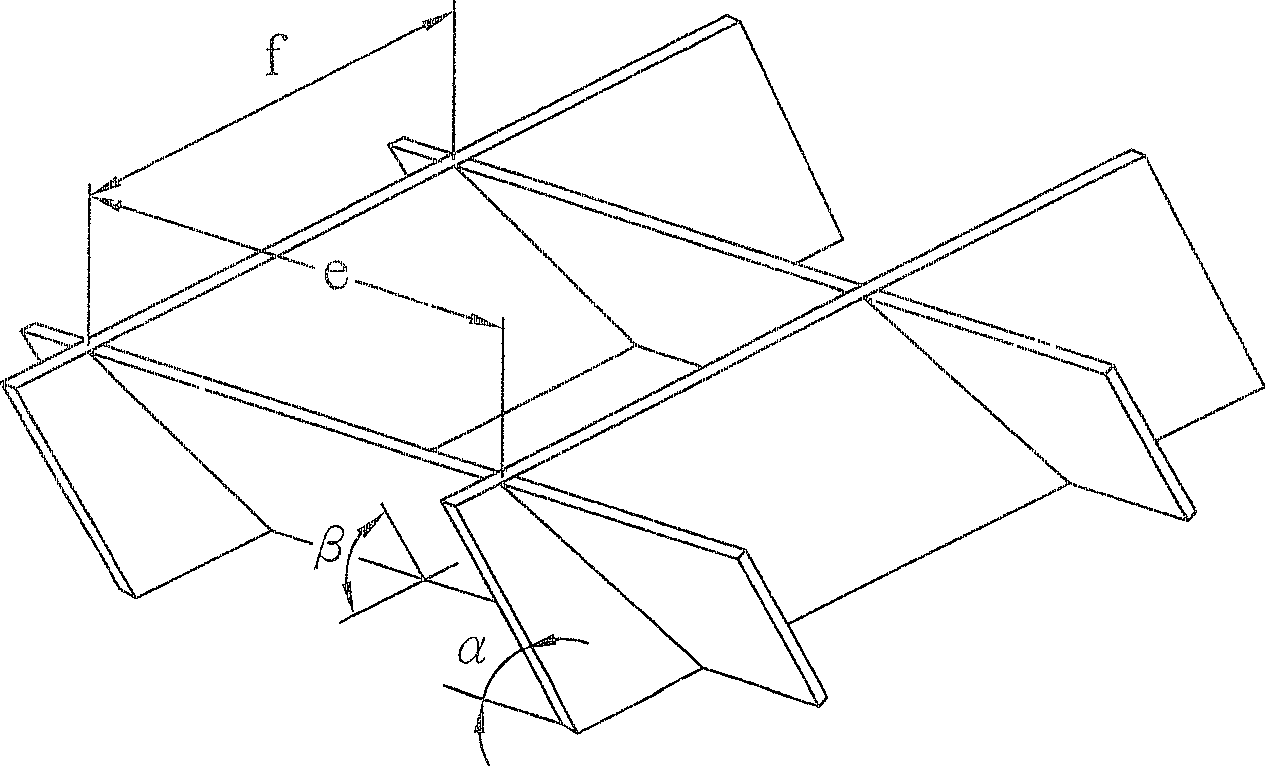

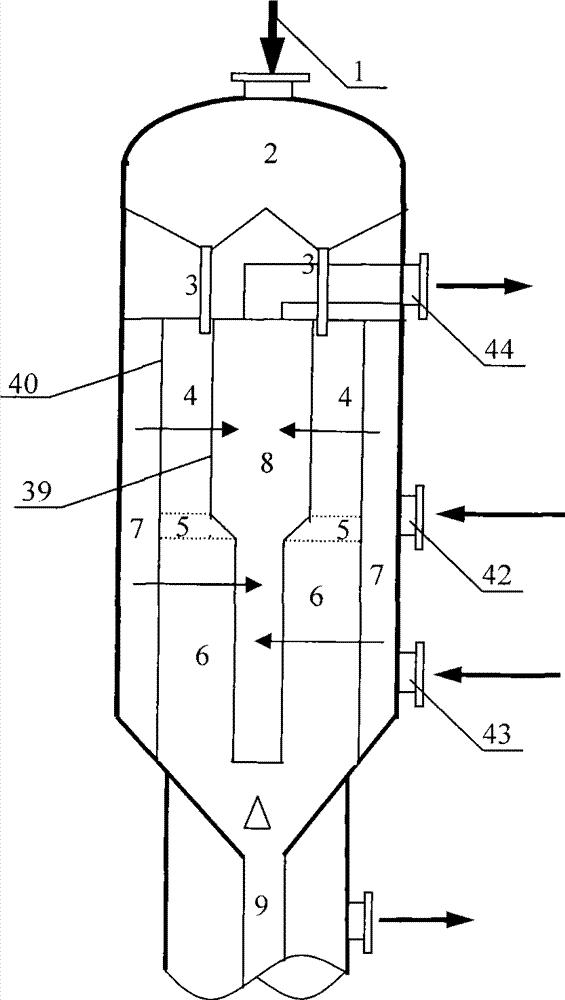

Fluidised bed gas and solid contacting device

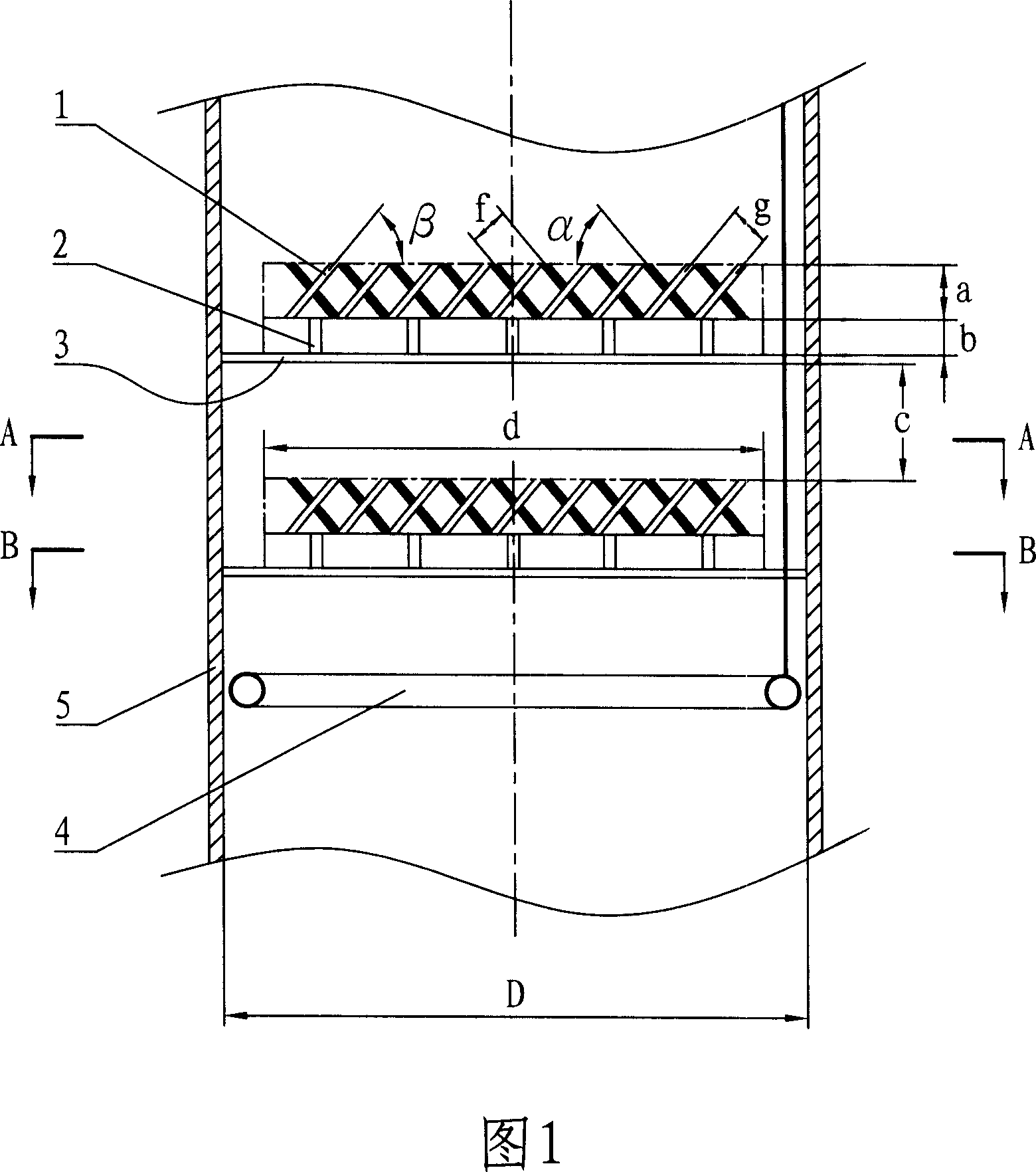

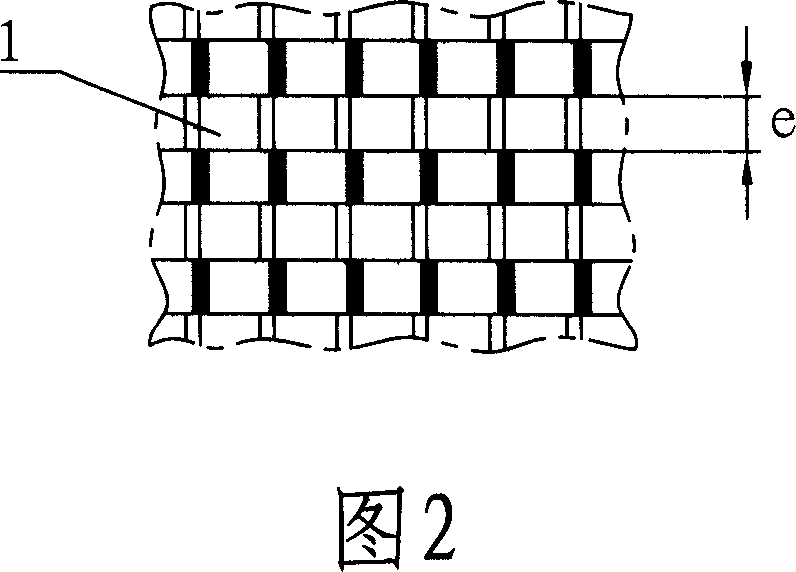

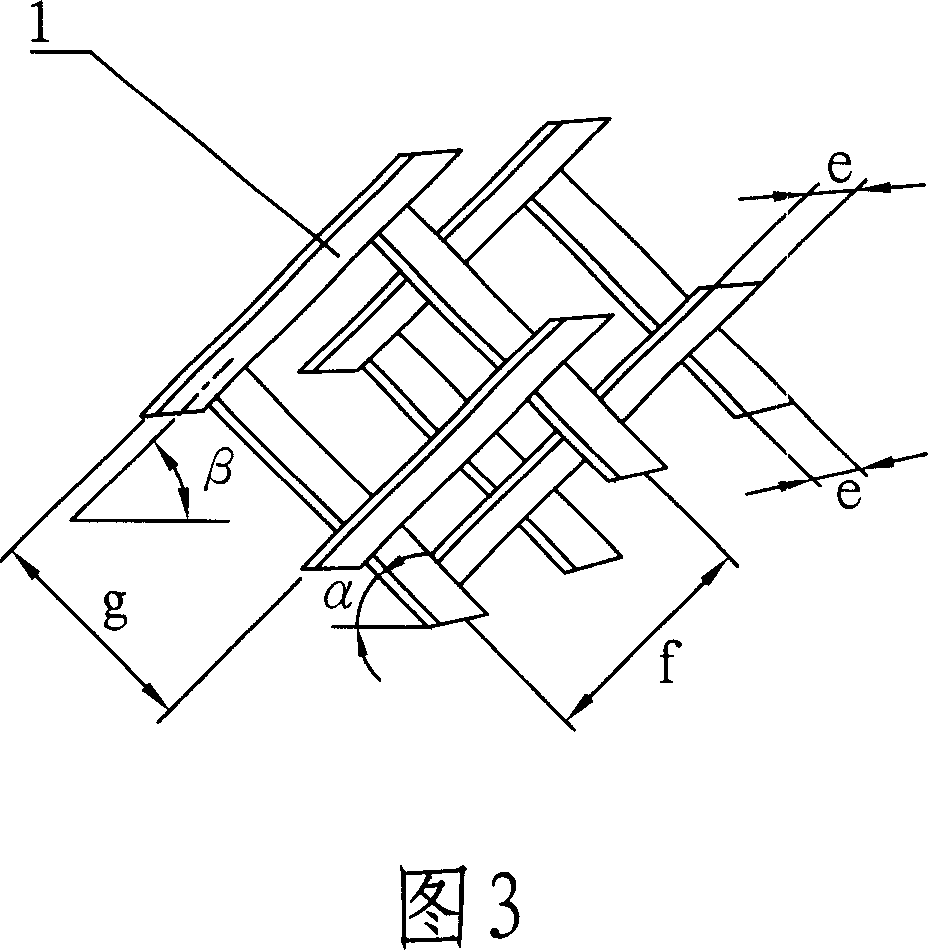

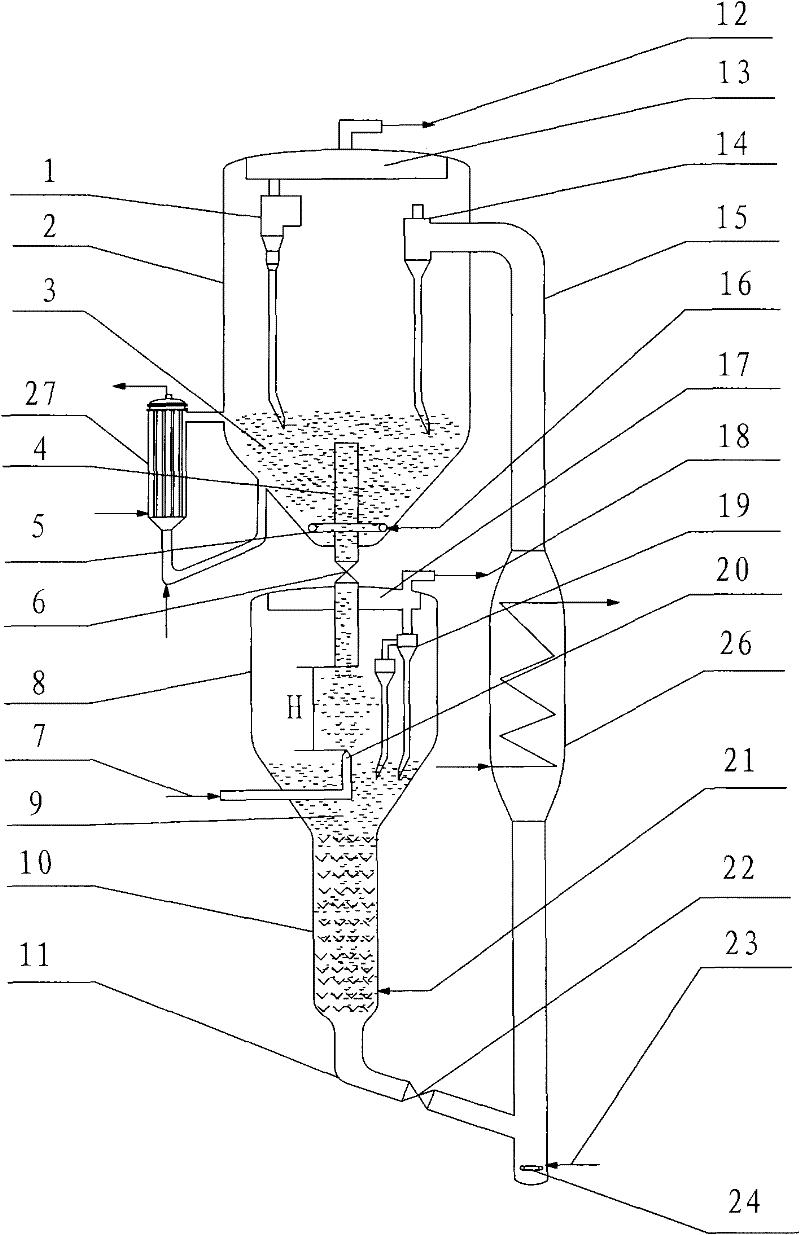

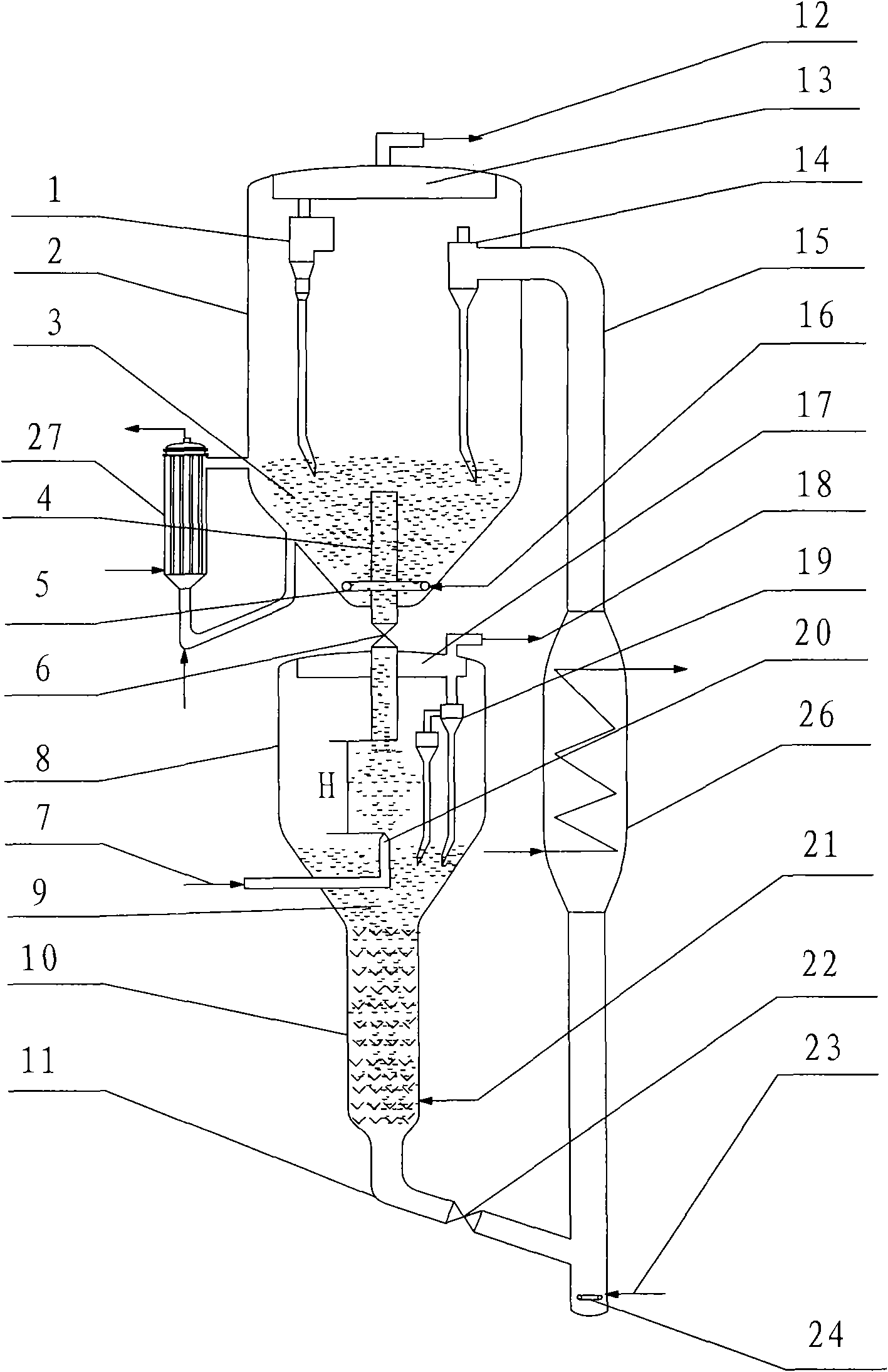

The invention discloses a fluidized bed gas-solid contacting device for the petrochemical processing catalytic conversion equipment, to resolve the problem of the existing device that the installation, maintain and maintenance is difficult and the stripping efficiency is low. The contacting device is mounted at least with two groups of filler layers along the axial of tunnel body (5), and the there is gap between the adjacent filler layers. Each group of filler layers is composed of a first filler layer (1) at the upper and a second filler layer (2) at the lower, which are contacted and supported on the support rack (3). The first filler layer is a filler layer with stereoscopic grid channels composed of rows of stripe boards, two adjacent of which has a different trend of the tilt with the horizontal plane and is intercrossed. The second filler layer is a filler layer with erective channels, and composed of stripe board groups, which is perpendicular to horizontal plane and intercrossed. The invention can be used as a steam stripping machine to steam strip the oil gas, hydrocarbon compound or gas impurities in the catalyst, and also used as a regenerator for the regeneration of catalyst.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Hydrocarbon conversion catalyst regeneration burning method and regenerator burning area structure

ActiveCN102218354AReduce the risk of burning out the inner screen due to overheatingThe overall thickness is thinCatalytic naphtha reformingCatalyst regeneration/reactivationPolymer scienceProduct gas

The invention discloses a hydrocarbon conversion catalyst regeneration burning method and a regenerator burning area structure, and solves the problems that a hydrocarbon conversion catalyst burning area has a temperature runaway risk and the like in the prior art. The method comprises the following steps of: introducing a catalyst to be regenerated into a radial catalyst moving bed burning area by means of gravity, contacting oxygen-containing regeneration gas, and burning carbon deposit on the catalyst; and introducing into a chlorine oxidation area under the action of gravity, wherein a catalyst moving bed in the burning area is provided with a quick firing section, a transition section and a superheat section from top to bottom in turn; and the thickness ratio of catalyst beds in the quick firing section and the superheat section is 0.25-1 and the height ratio is 1-8.

Owner:CHINA PETROCHEMICAL CORP +1

Coke-burning method for hydrocarbon conversion catalyst regeneration and structure of coke-burning area of regenerator

ActiveCN102218353AReduce the risk of burning out the inner screen due to overheatingThe overall thickness is thinCatalyst regeneration/reactivationChemistryTemperature jump

The invention discloses a coke-burning method for hydrocarbon conversion catalyst regeneration and a structure of a coke-burning area of a regenerator. The invention solves the disadvantage of the temperature jump risk in a coke-burning area of a hydrocarbon conversion catalyst in the prior art. The method comprises the following steps: allowing a catalyst to be regenerated to enter a coke-burning area of a radial catalyst moving bed under gravity, allowing the catalyst to contact an oxygen-containing regenerating gas and burning out coke deposits on the catalyst, and allowing the catalyst to enter a chlorine oxidation area, wherein the coke-burning area of the catalyst moving bed comprises an inner screen and an outer screen; the lower diameter is larger than the upper diameter of the outer screen; the upper and the lower parts of the outer screen are connected by a conical structure; the outer screen with different diameters and the inner screen forms, from up to down, an upper quick-burning section, an intermediate transition section, and a lower overheating section of the coke-burning area; and the thickness ratio of the catalyst bed layers of the quick-burning section and the overheating section is 0.25-1, and the height ratio is 1-8.

Owner:CHINA PETROCHEMICAL CORP +1

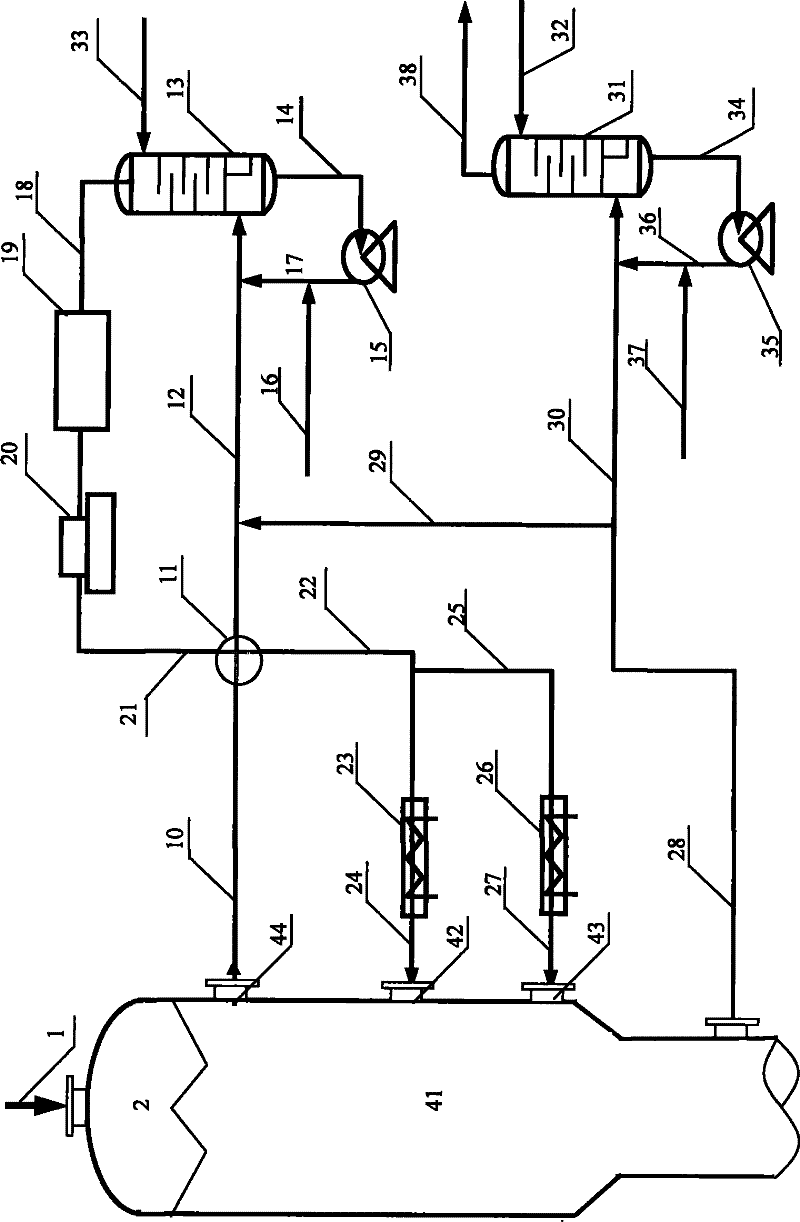

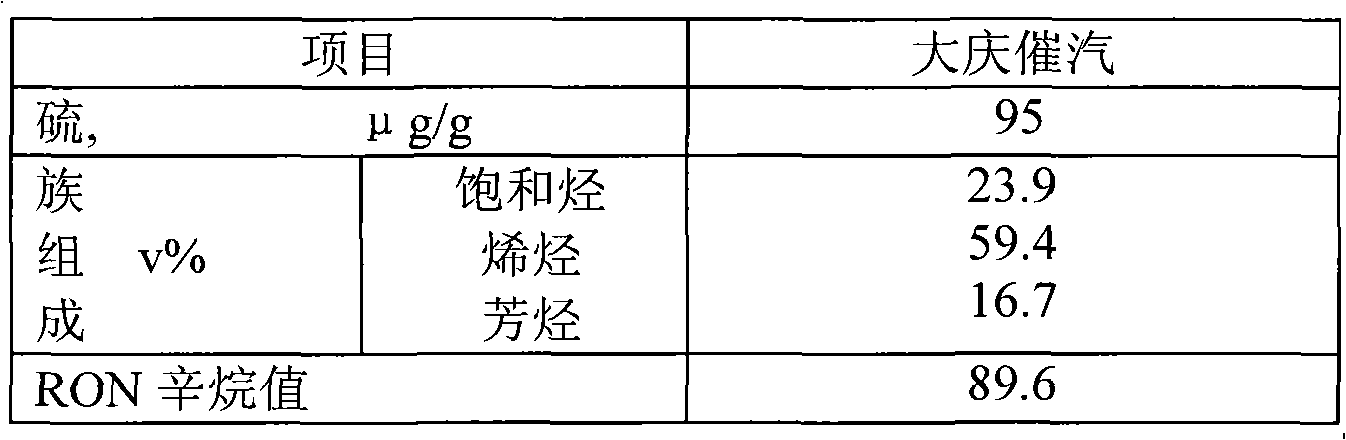

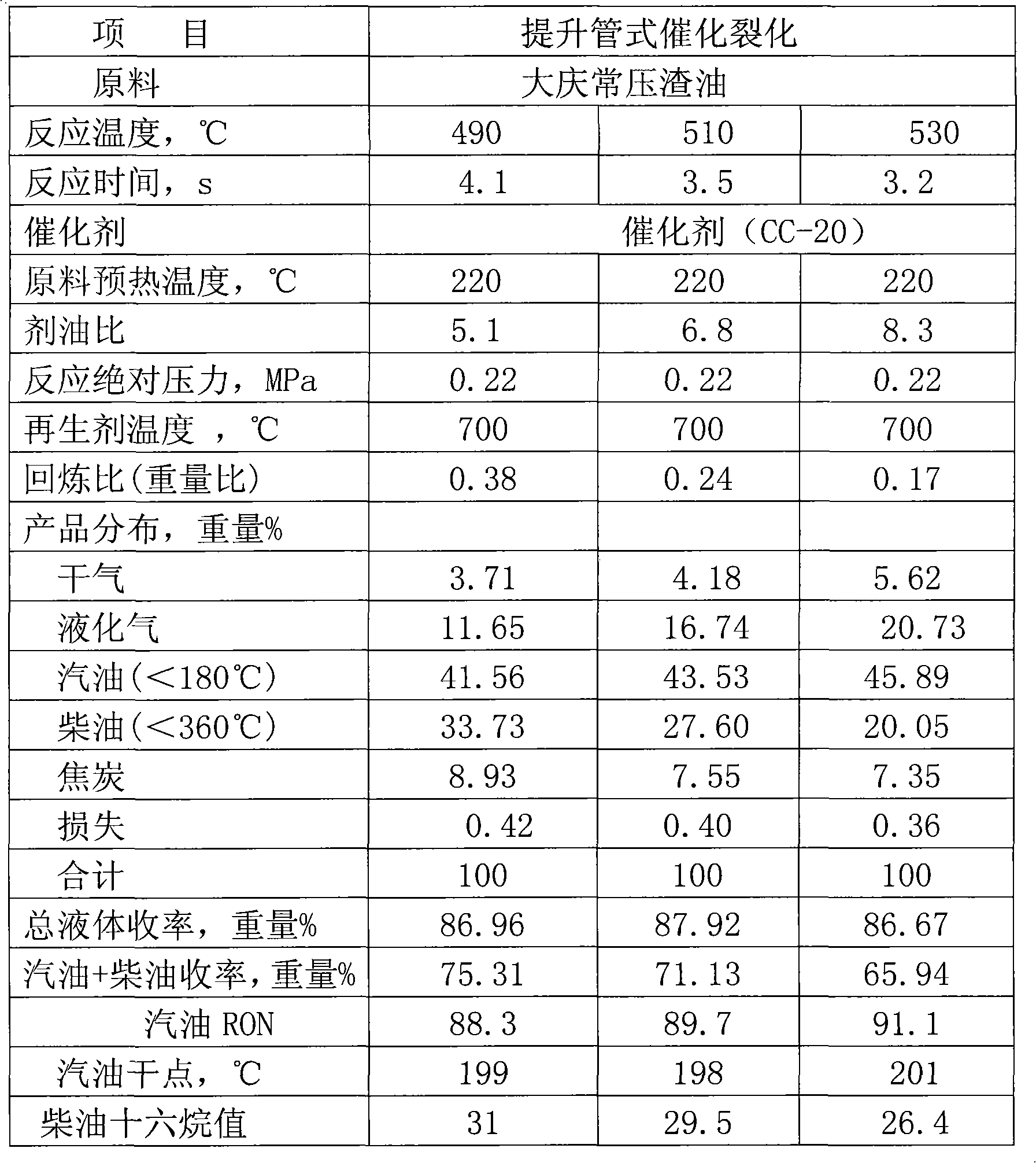

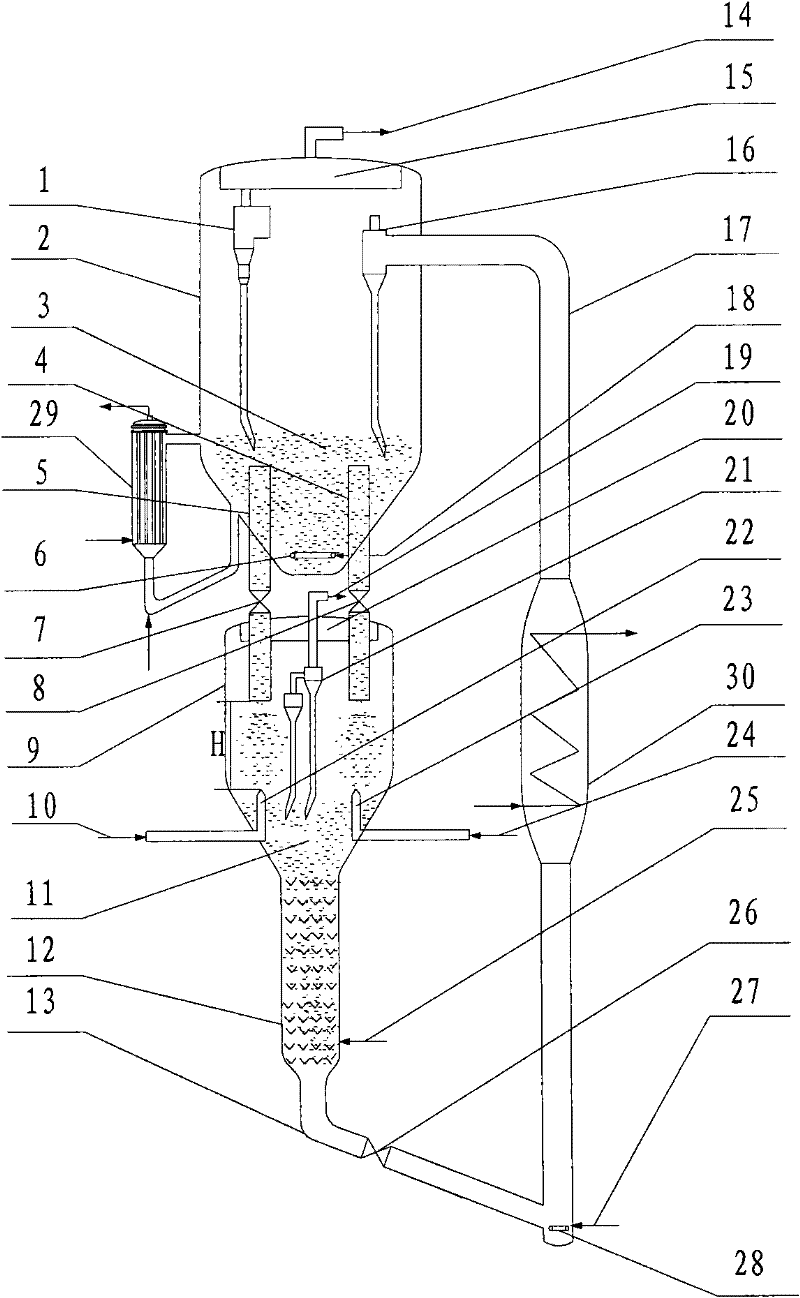

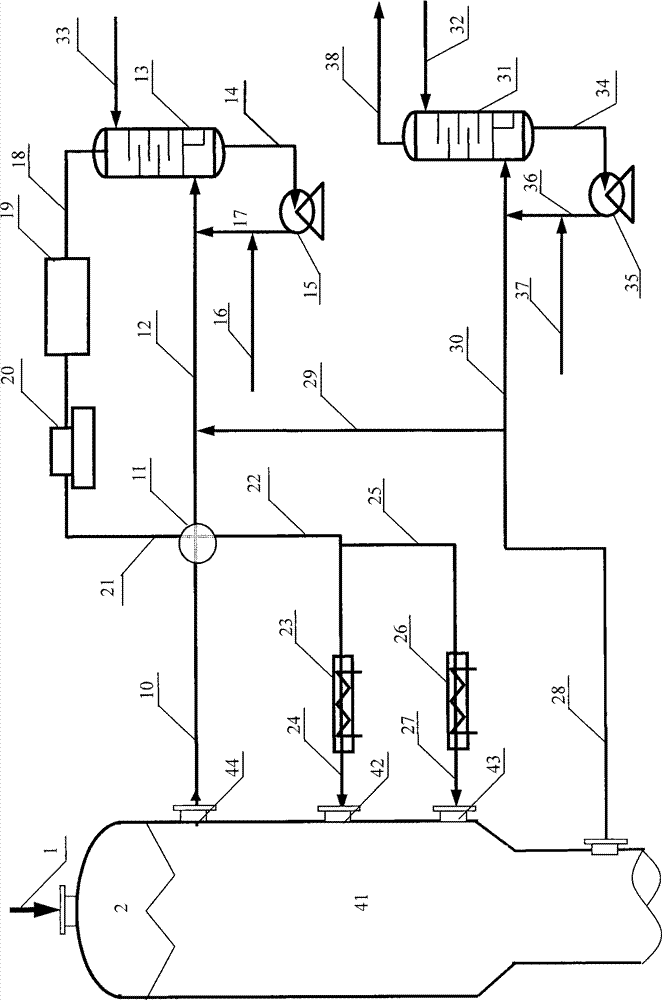

Gasoline olefin reducing catalytic cracking method and device

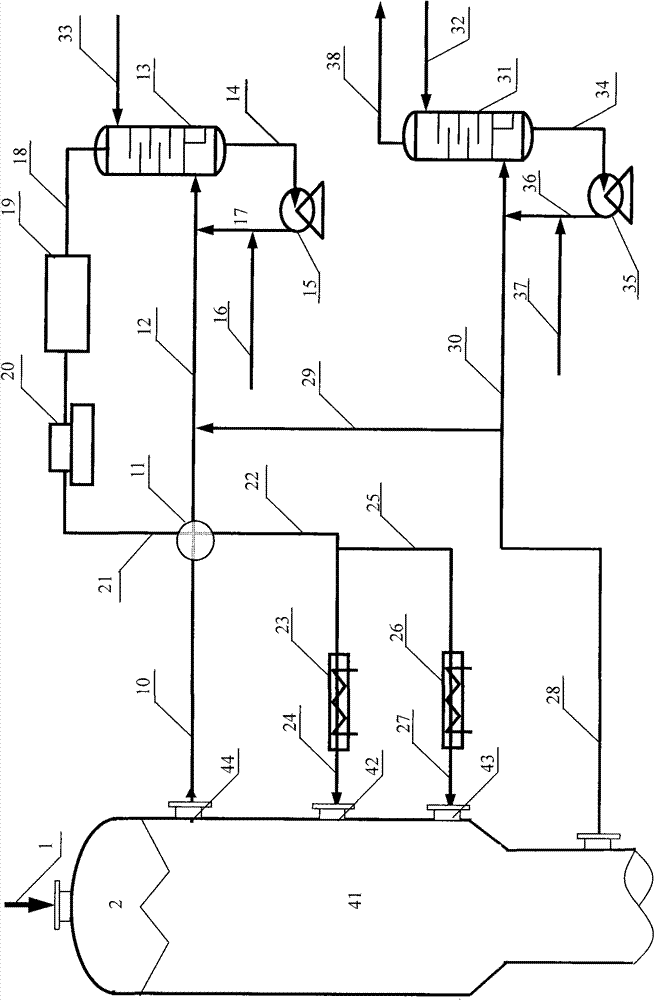

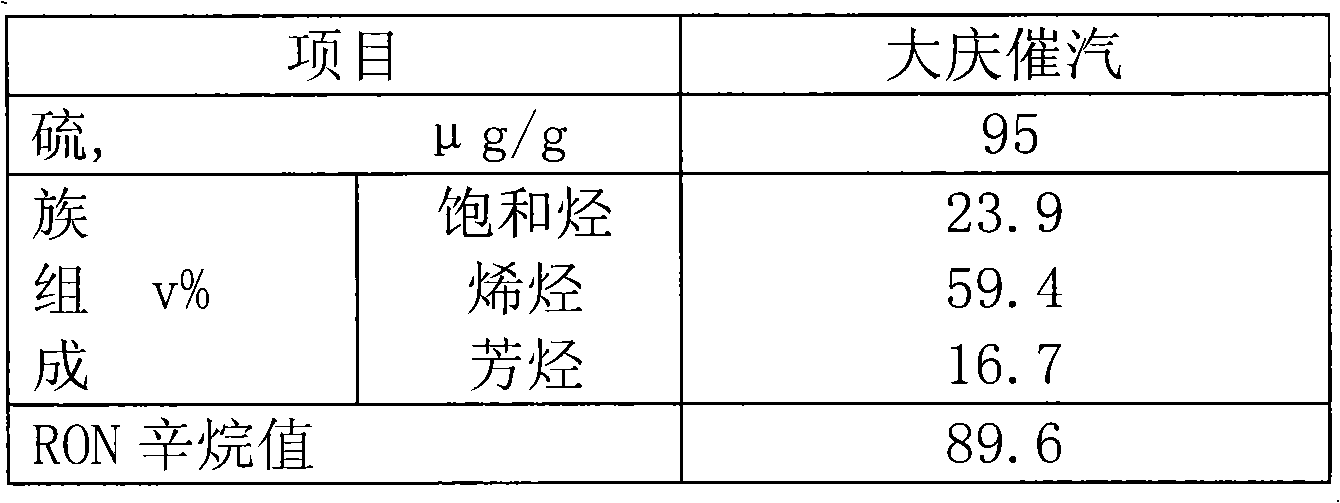

ActiveCN102311767AHigh yieldReduce olefin contentTreatment with plural parallel cracking stages onlyGasolineFuel oil

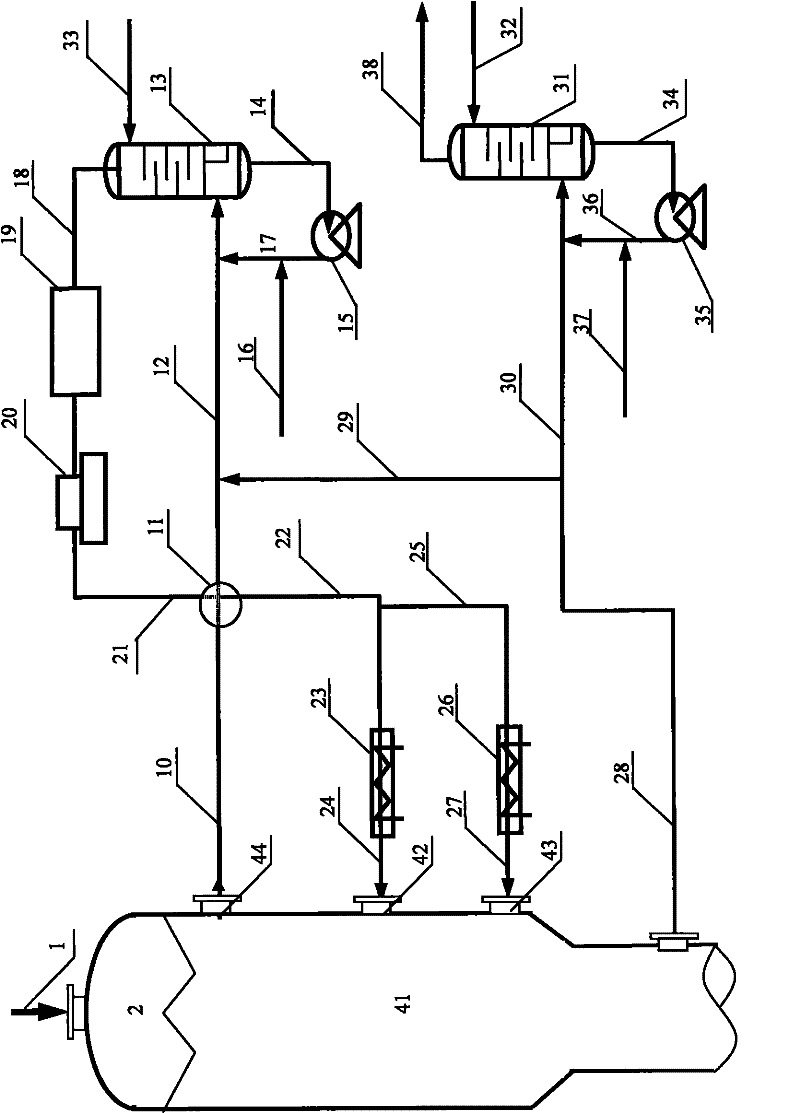

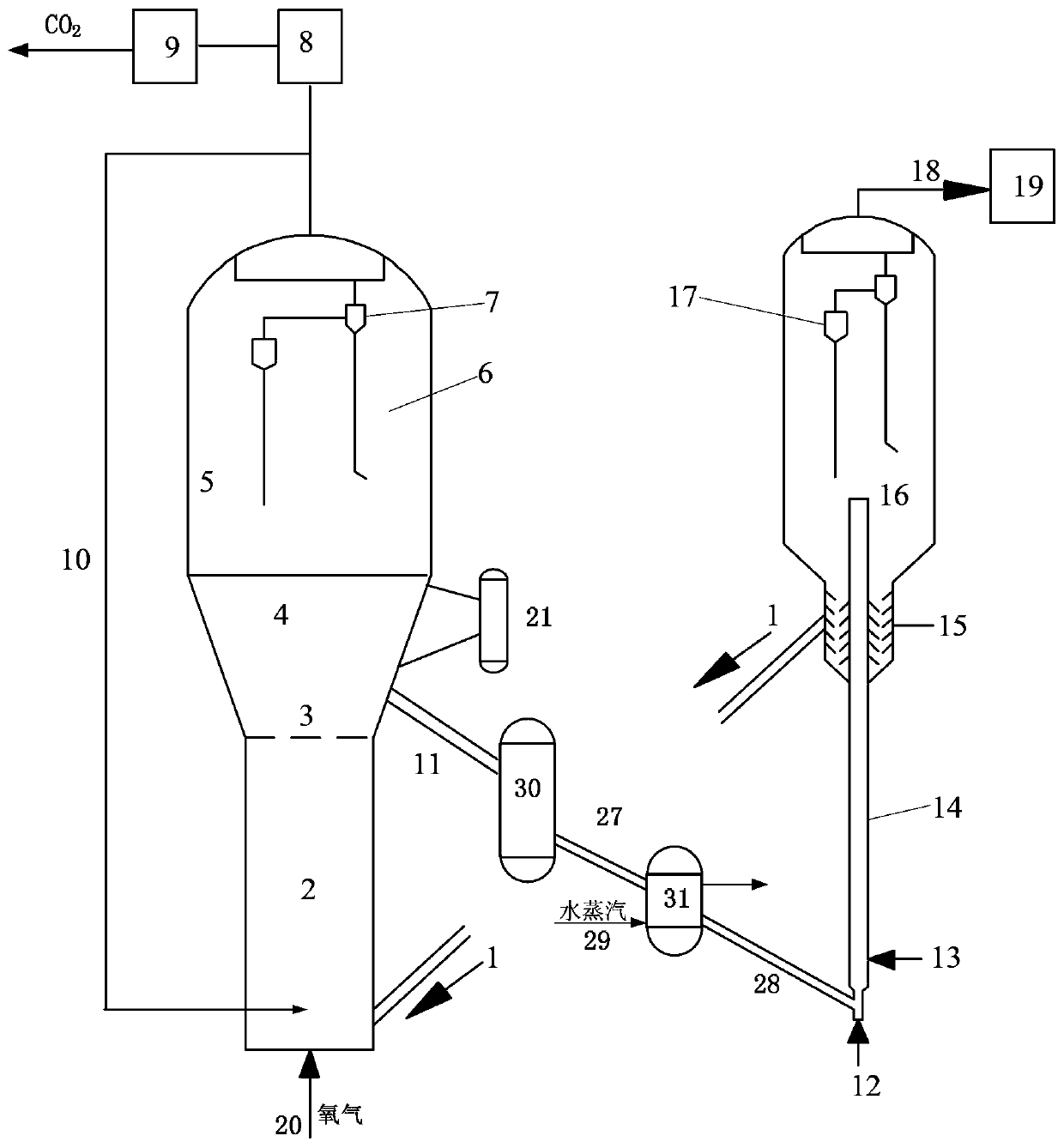

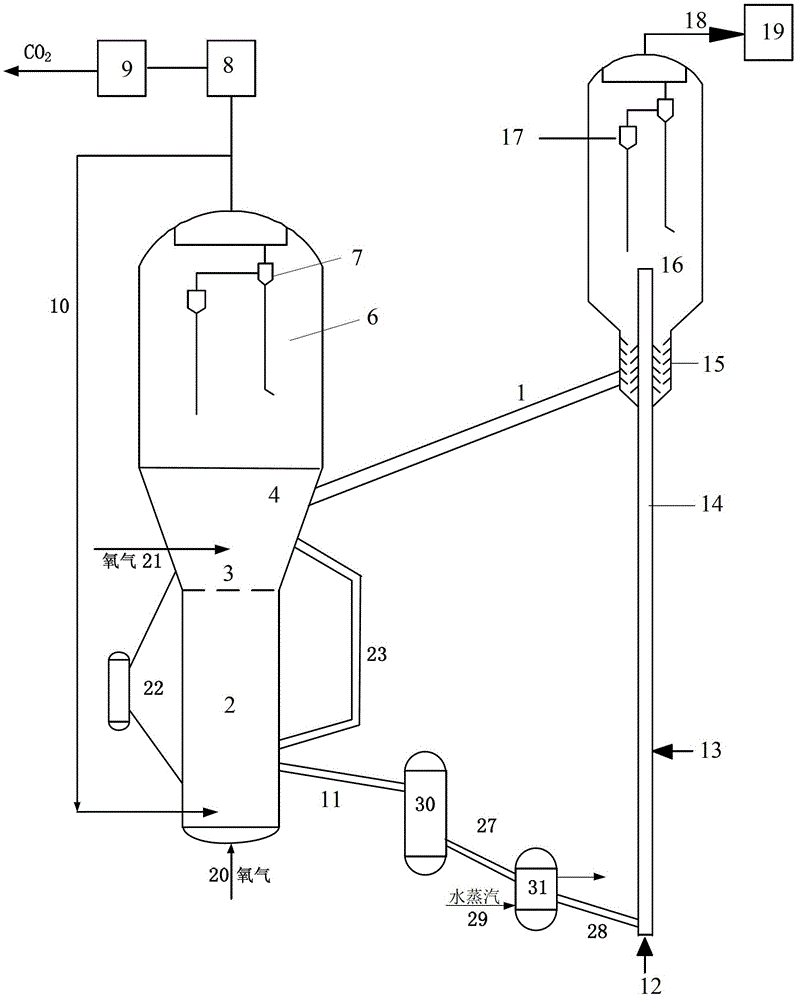

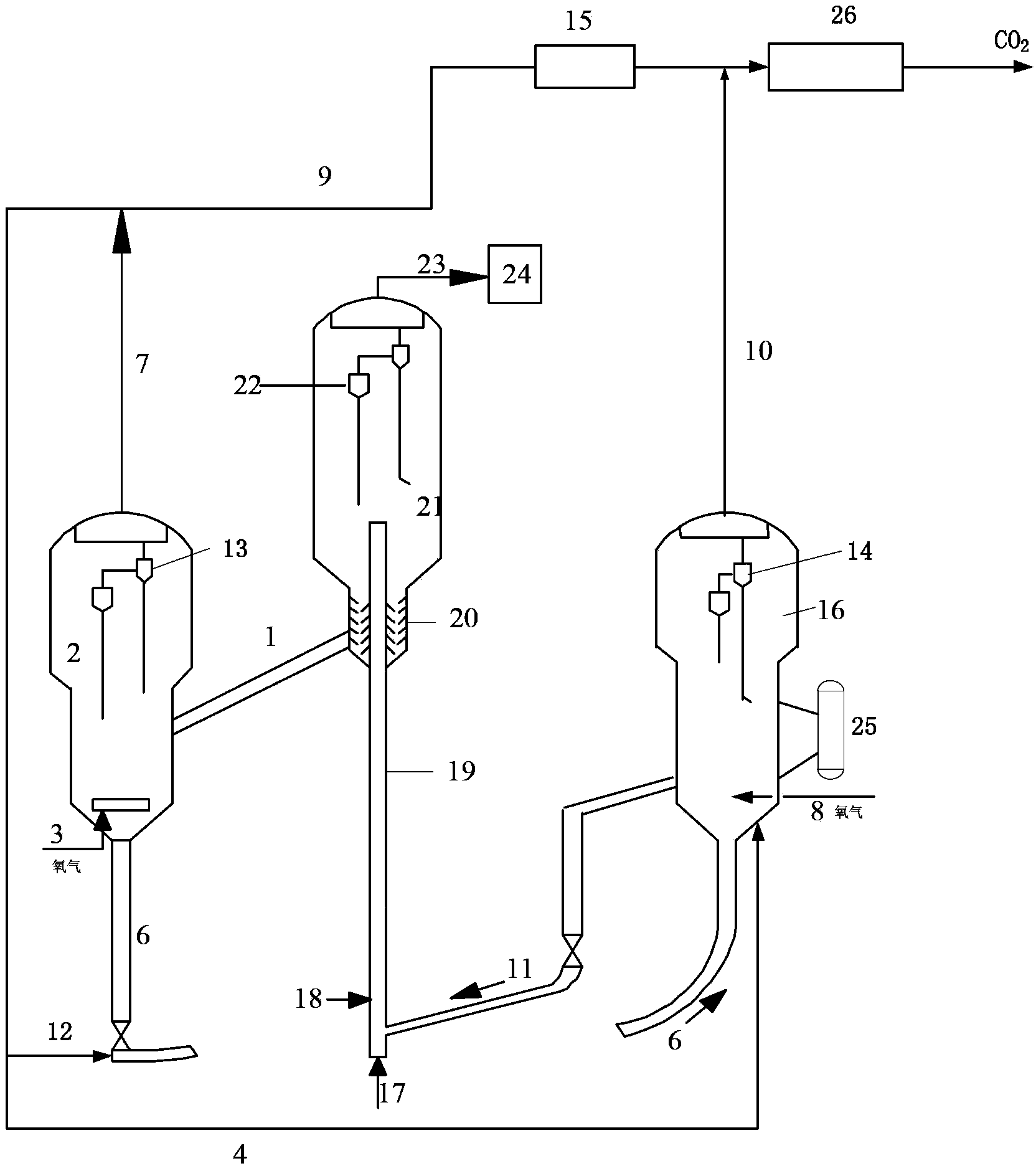

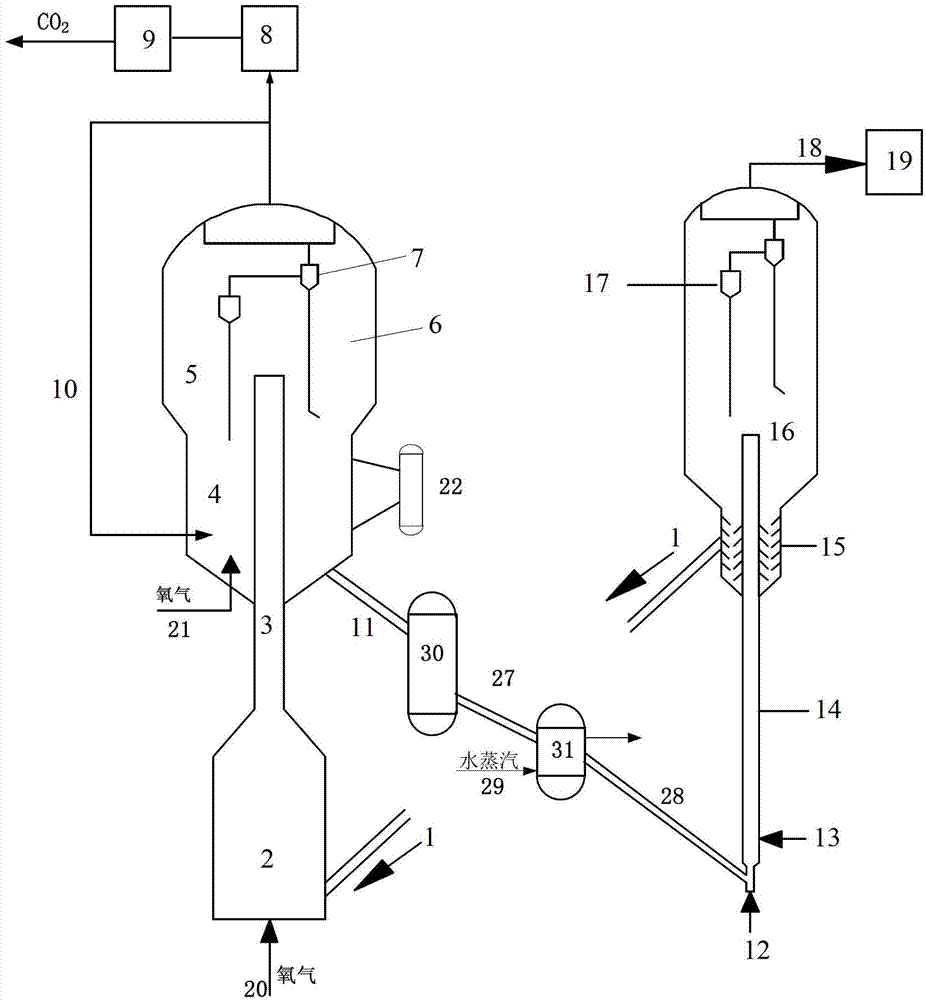

The invention discloses a gasoline olefin reducing catalytic cracking method and a gasoline olefin reducing catalytic cracking device. In the method and the device, a renewable catalyst is contacted with heavy oil and low-quality gasoline through conveying pipes for reactions respectively, the reaction oil gases enter a fractioning system respectively, the catalyst to be renewed is renewed in a tubular coke burning device and a catalyst dense-phase bed, and the renewed catalyst is used circularly. When the method and the device are used, the drawbacks of nonflexible control of catalyst temperature, high renewable catalyst and raw material contact temperature, long reaction time, low agent to oil ratio, low coke burning capacity of the device and the like are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

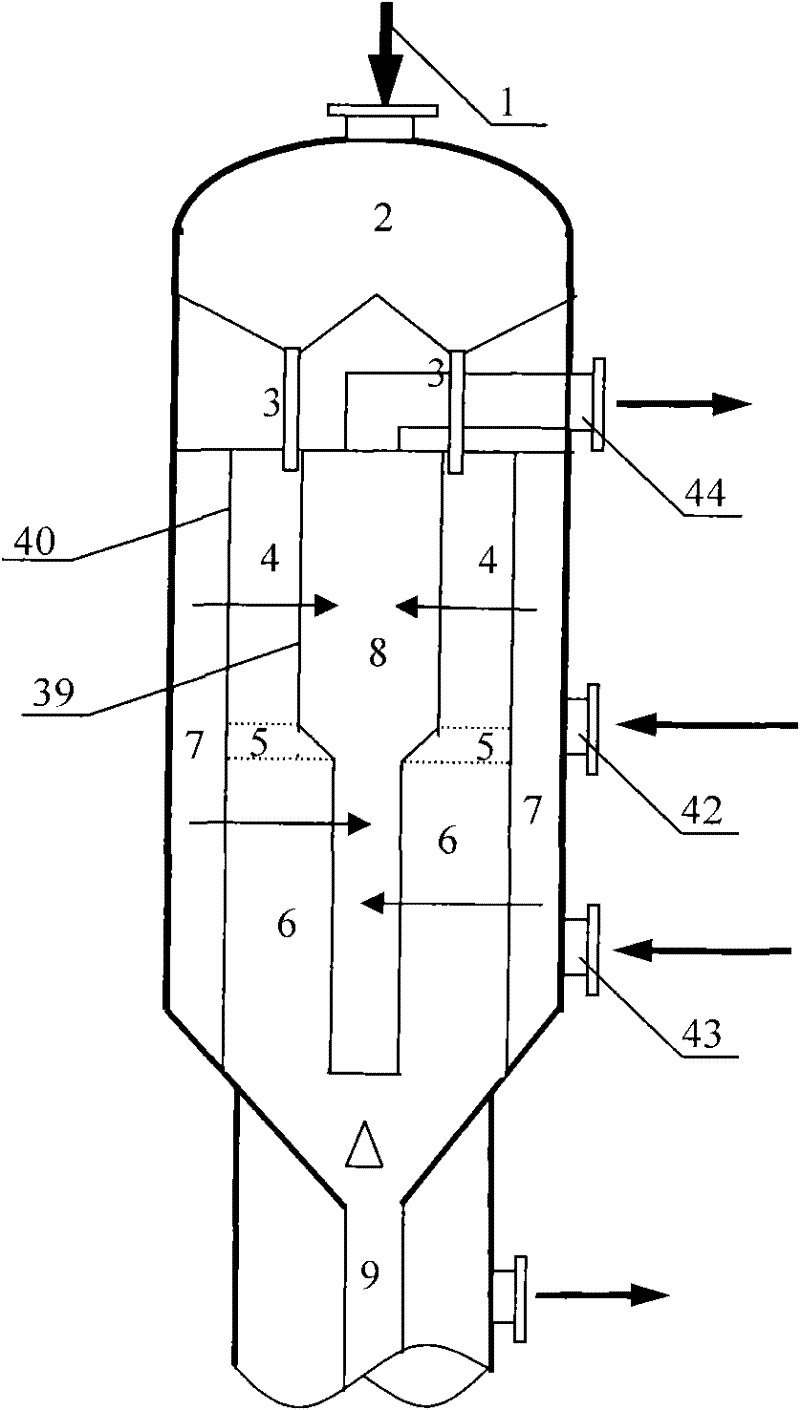

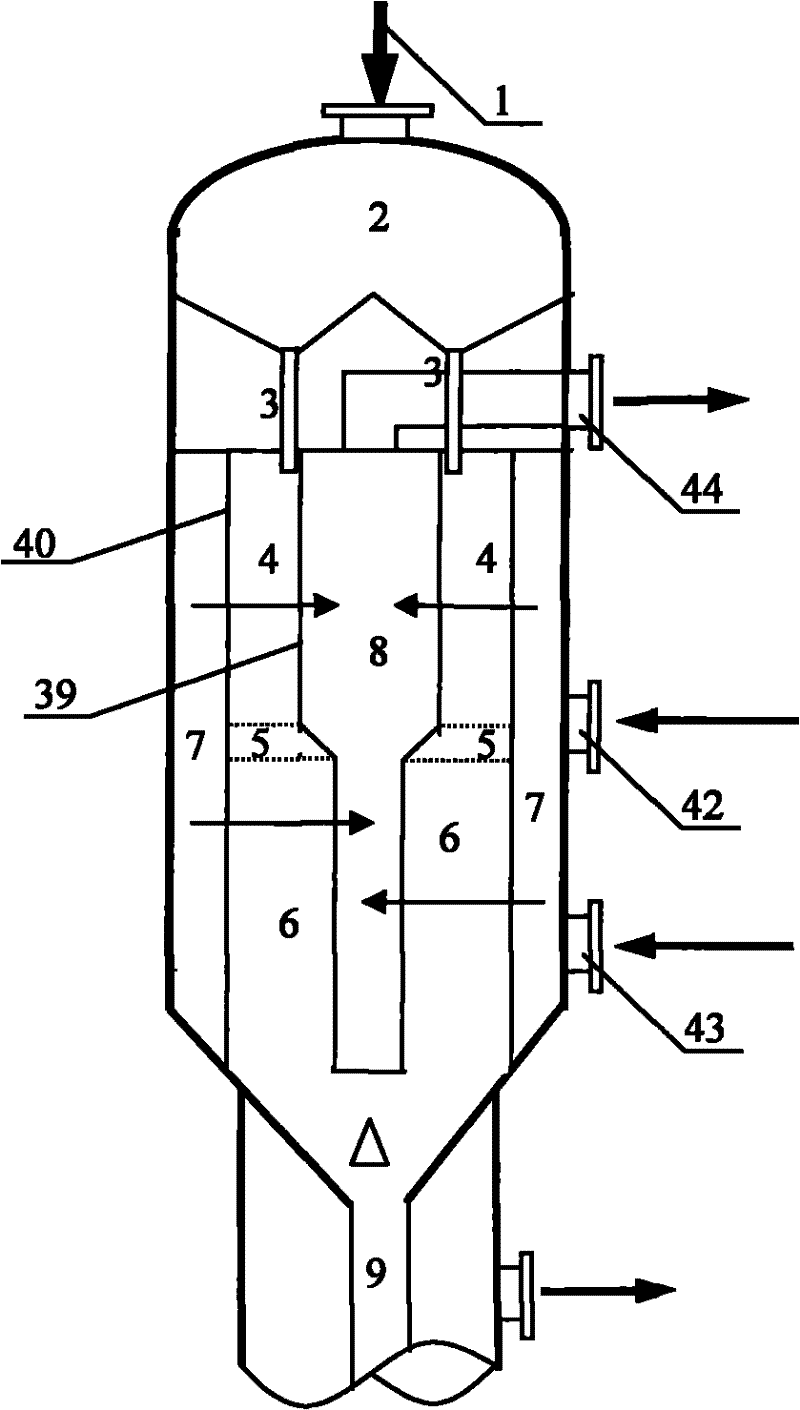

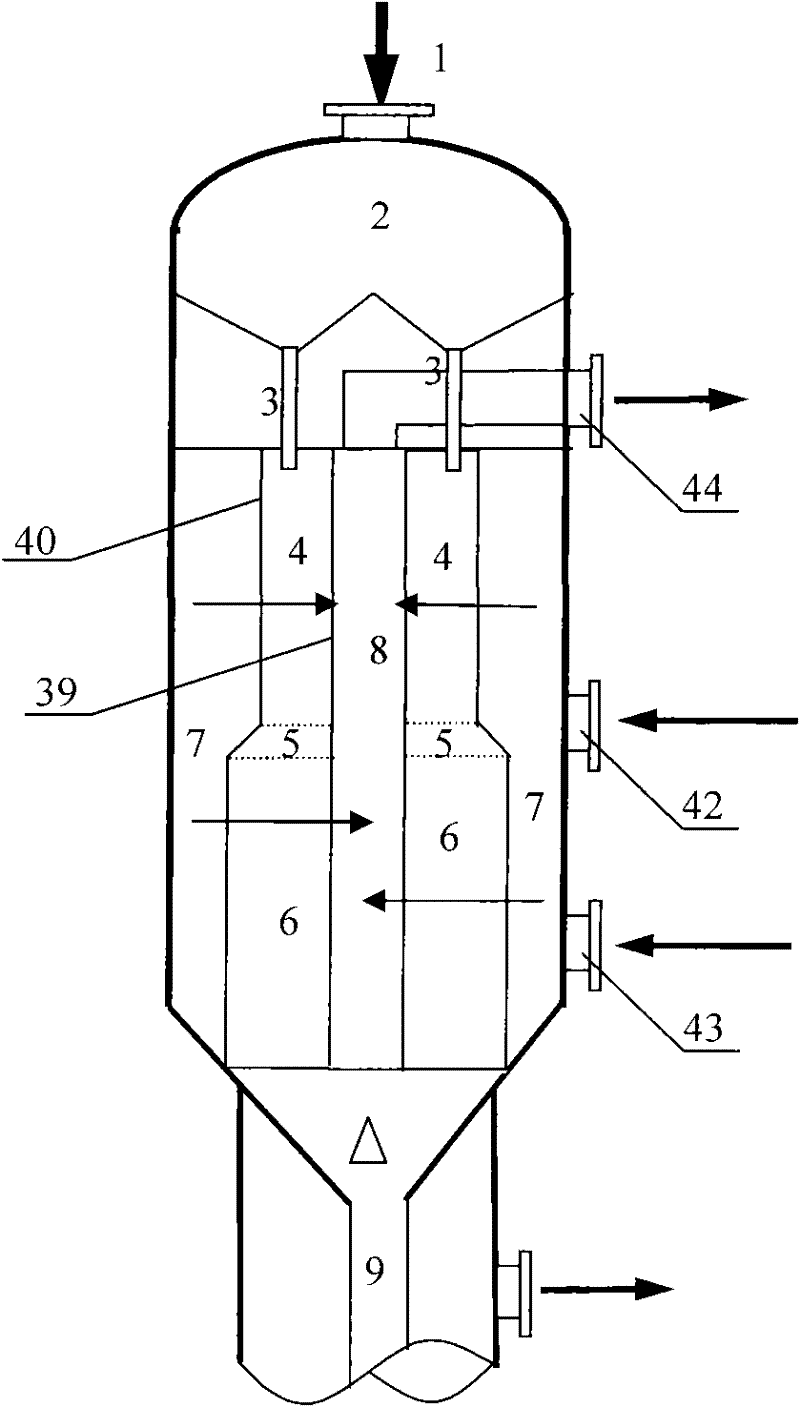

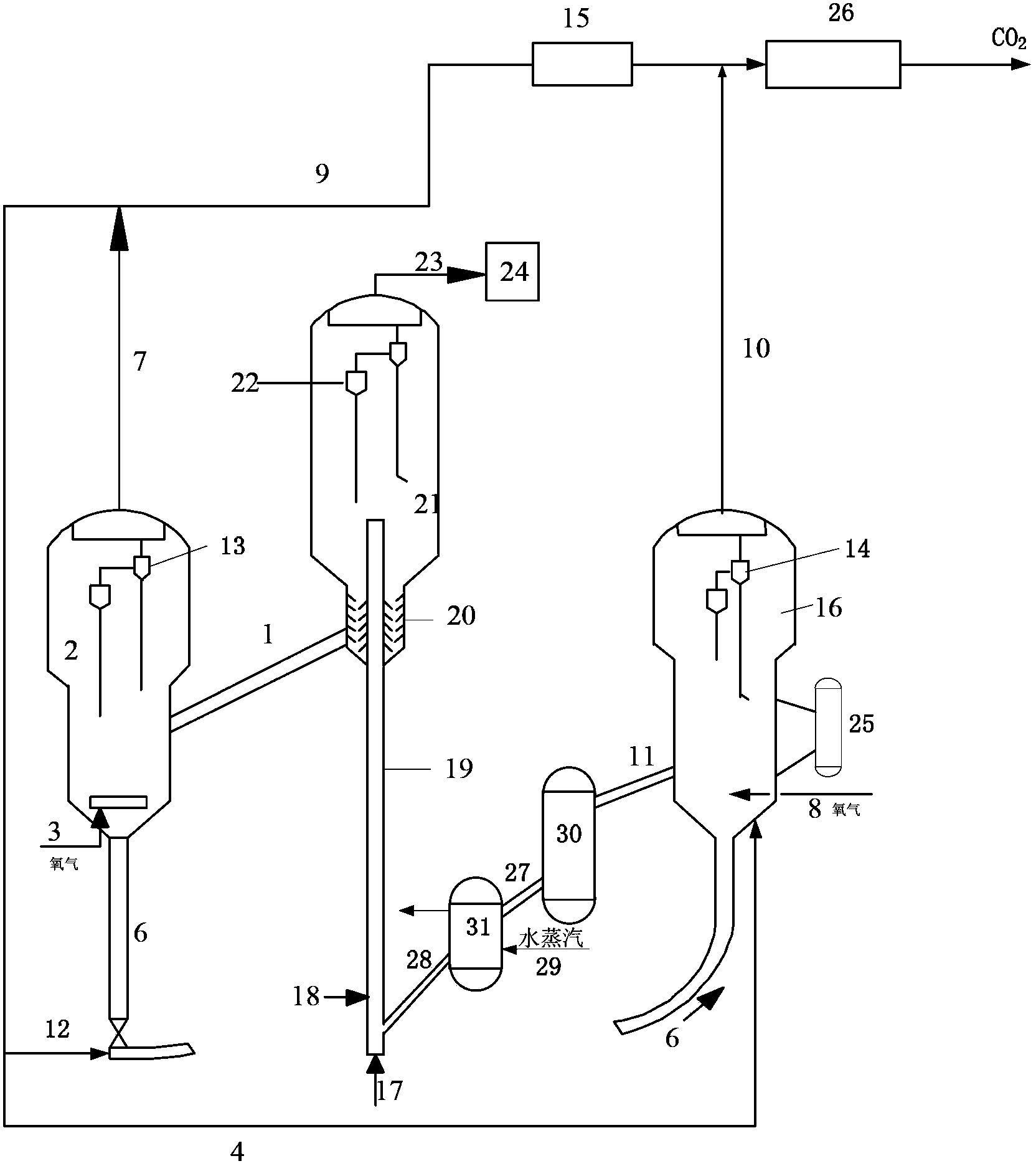

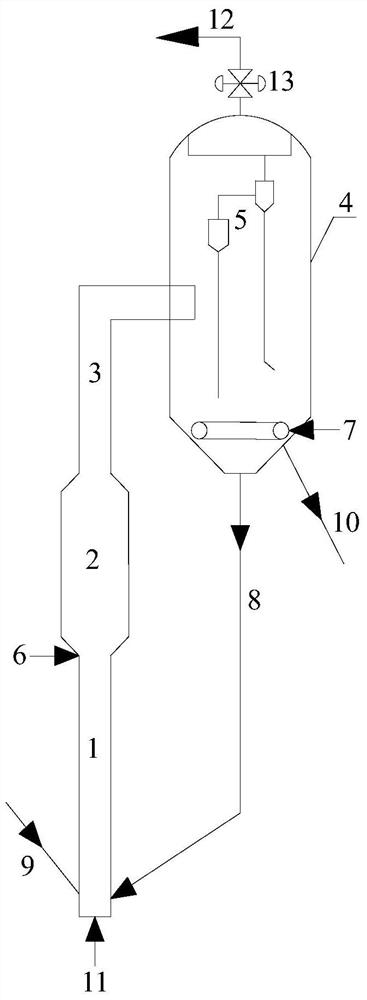

A catalytic cracking process and device for reducing gasoline olefins

ActiveCN102268291AIncreased charring capacityIncreased char strengthCatalytic crackingTreatment with plural serial stages onlyFlue gasFractionation

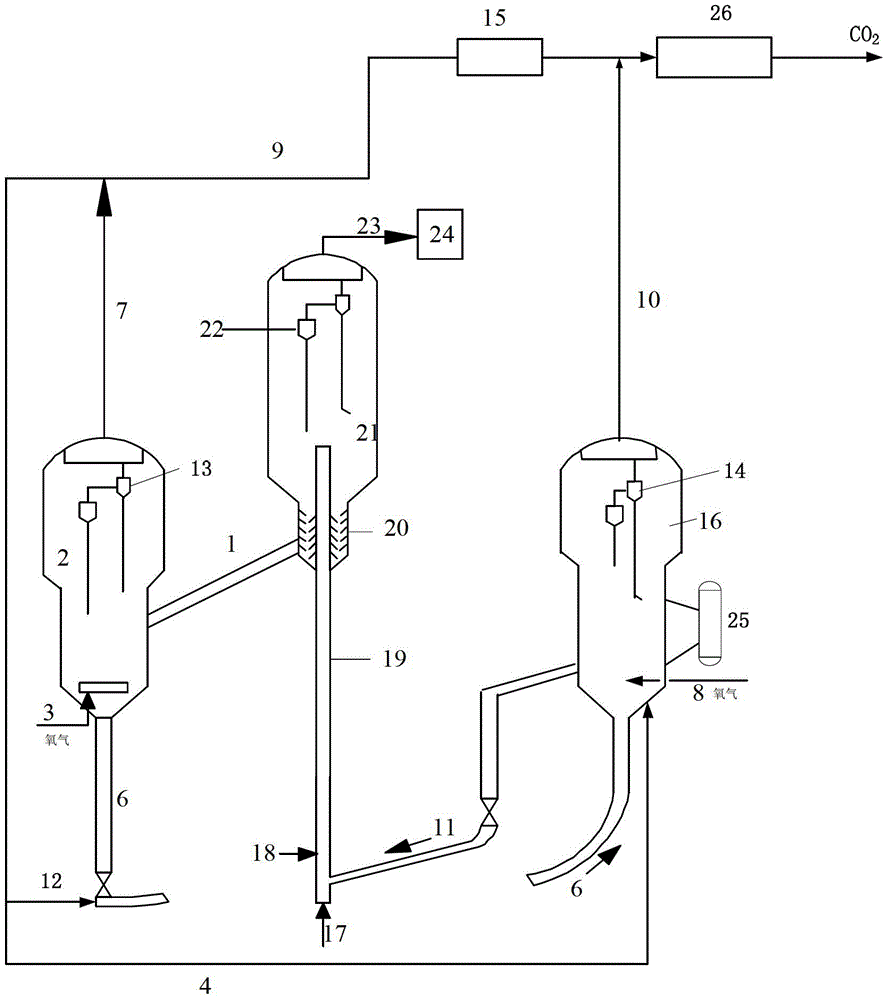

The invention discloses a catalytic cracking technology and a device for reducing olefins in gasoline. The catalytic cracking technology comprises the following steps that a regenerated catalyst is divided into two groups and the two groups are fed into a reaction sedimentation device and undergo contact reactions respectively with heavy feedstock and inferior gasoline feedstock; reaction productflows obtained from the previous step are separated; the separated reaction product oil gas is fed into a fractionation system to be fractionated and the separated catalyst needing to be regenerated is fed into a tube-type burning device to be subjected to burning regeneration; the regenerated catalyst obtained by the previous step is fed into a cyclone separator in a regenerator to be subjected to separation of the regenerated catalyst from flue gas; then the separated flue gas is discharged from the regenerator and the separated semi-regenerated catalyst is fed into a regenerator catalyst dense bed to be subjected to burning regeneration; and the regenerated catalyst obtained by the previous step is recycled.

Owner:CHINA PETROCHEMICAL CORP +1

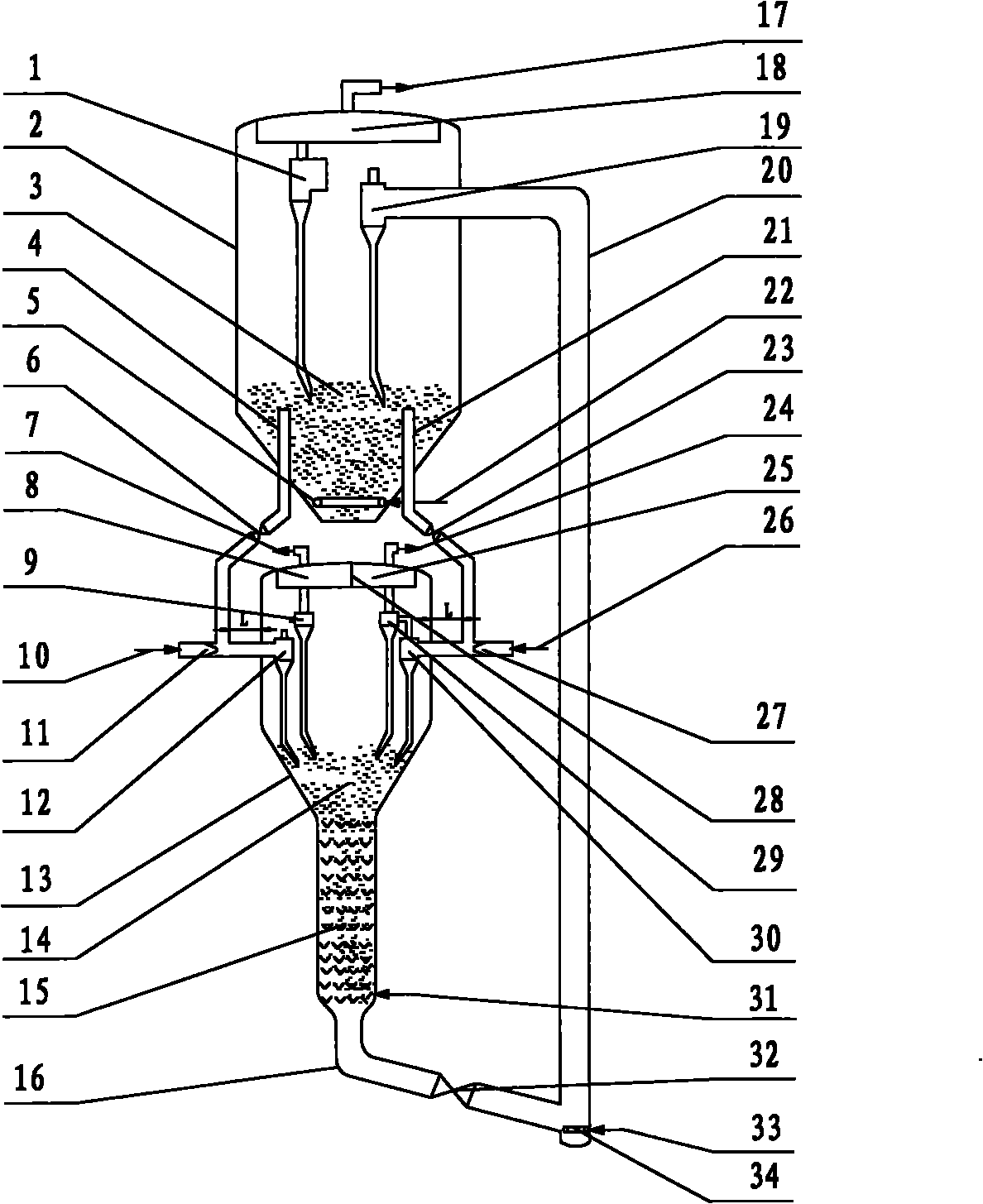

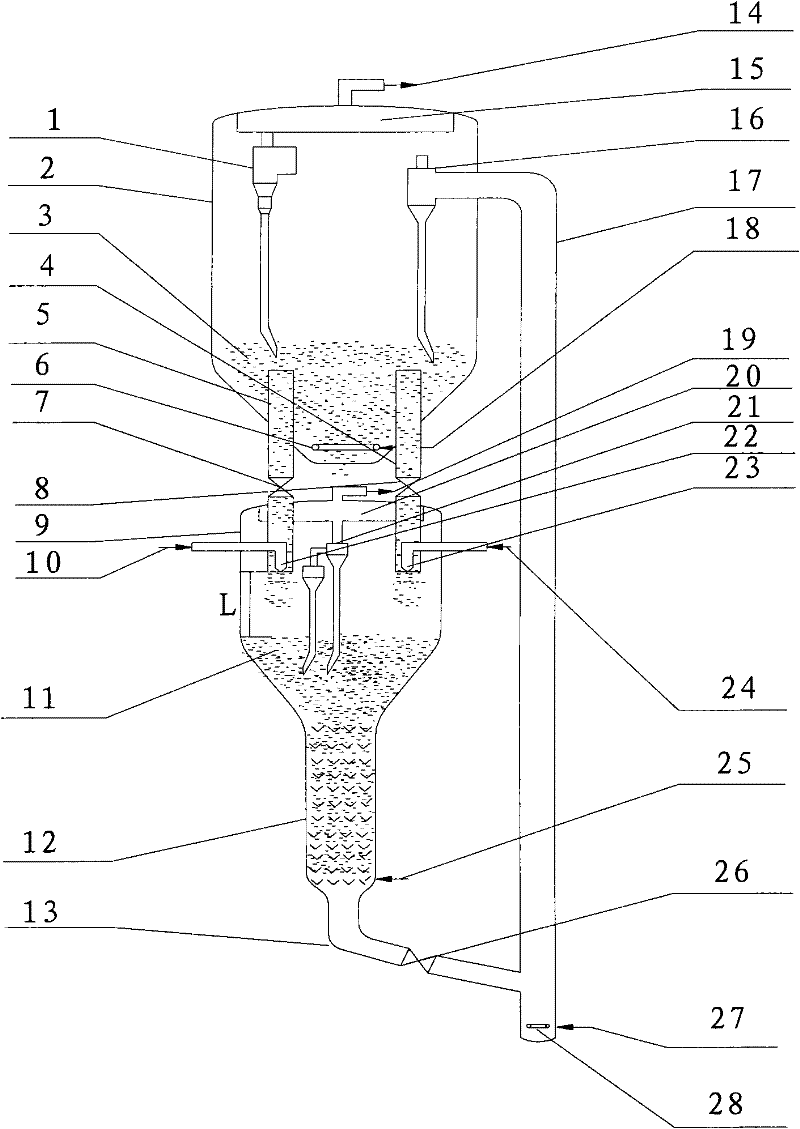

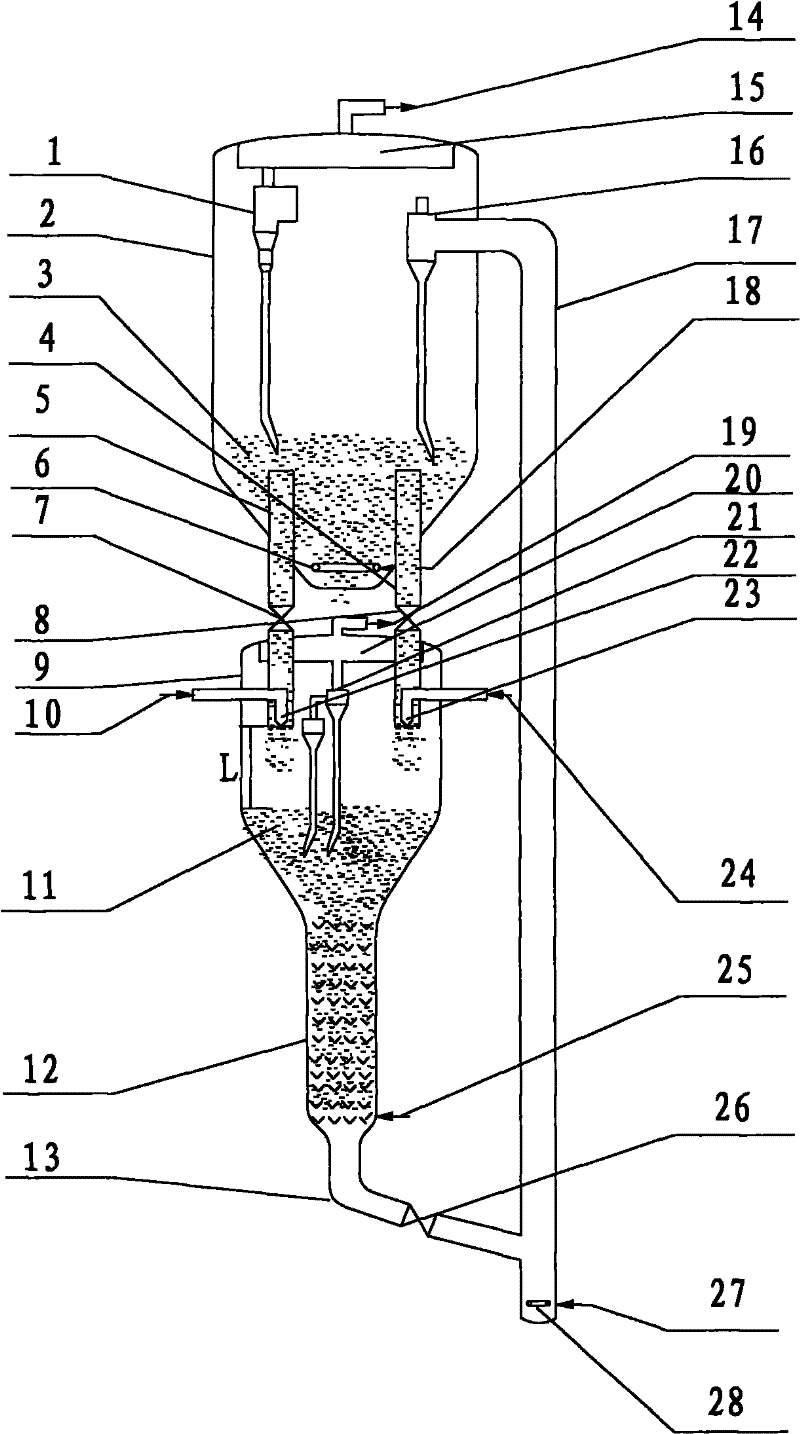

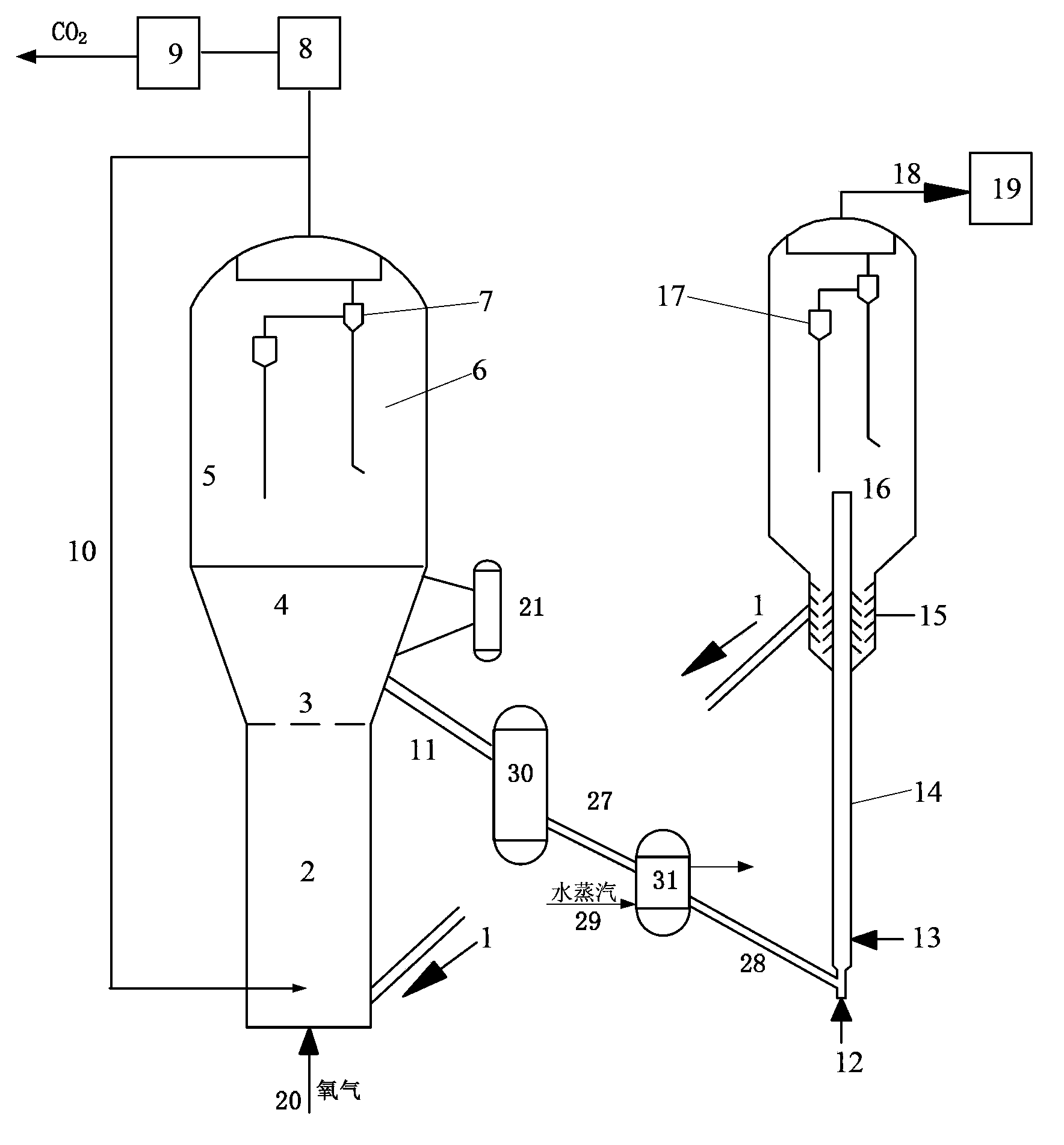

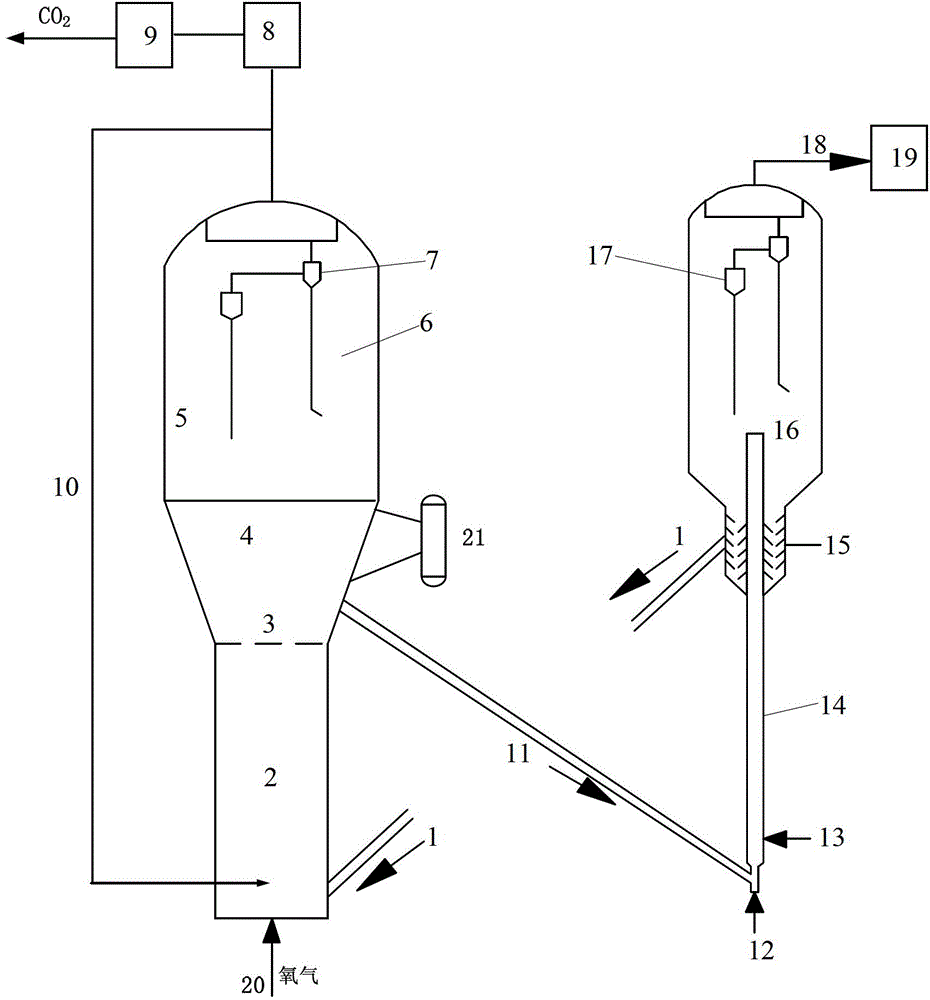

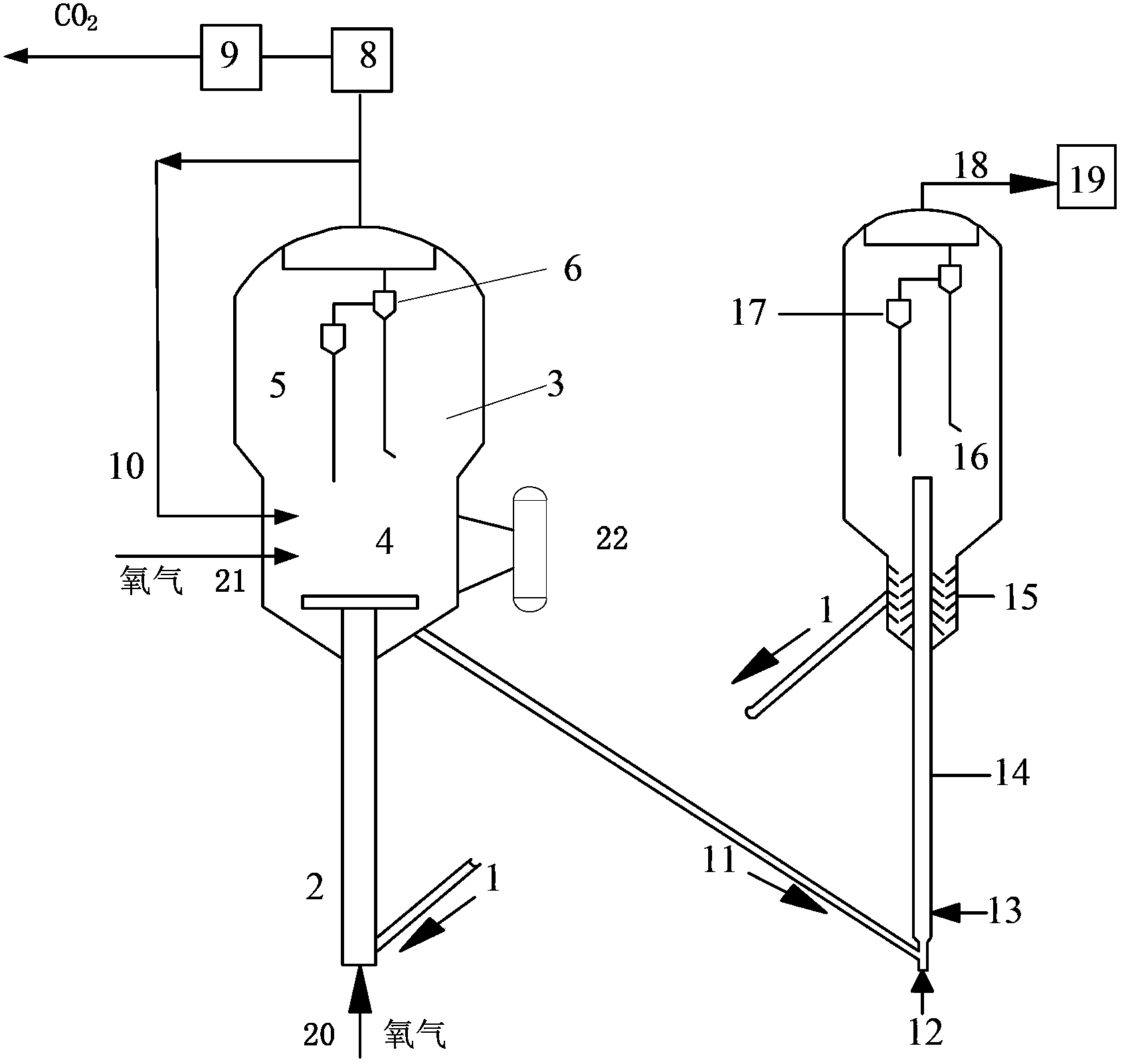

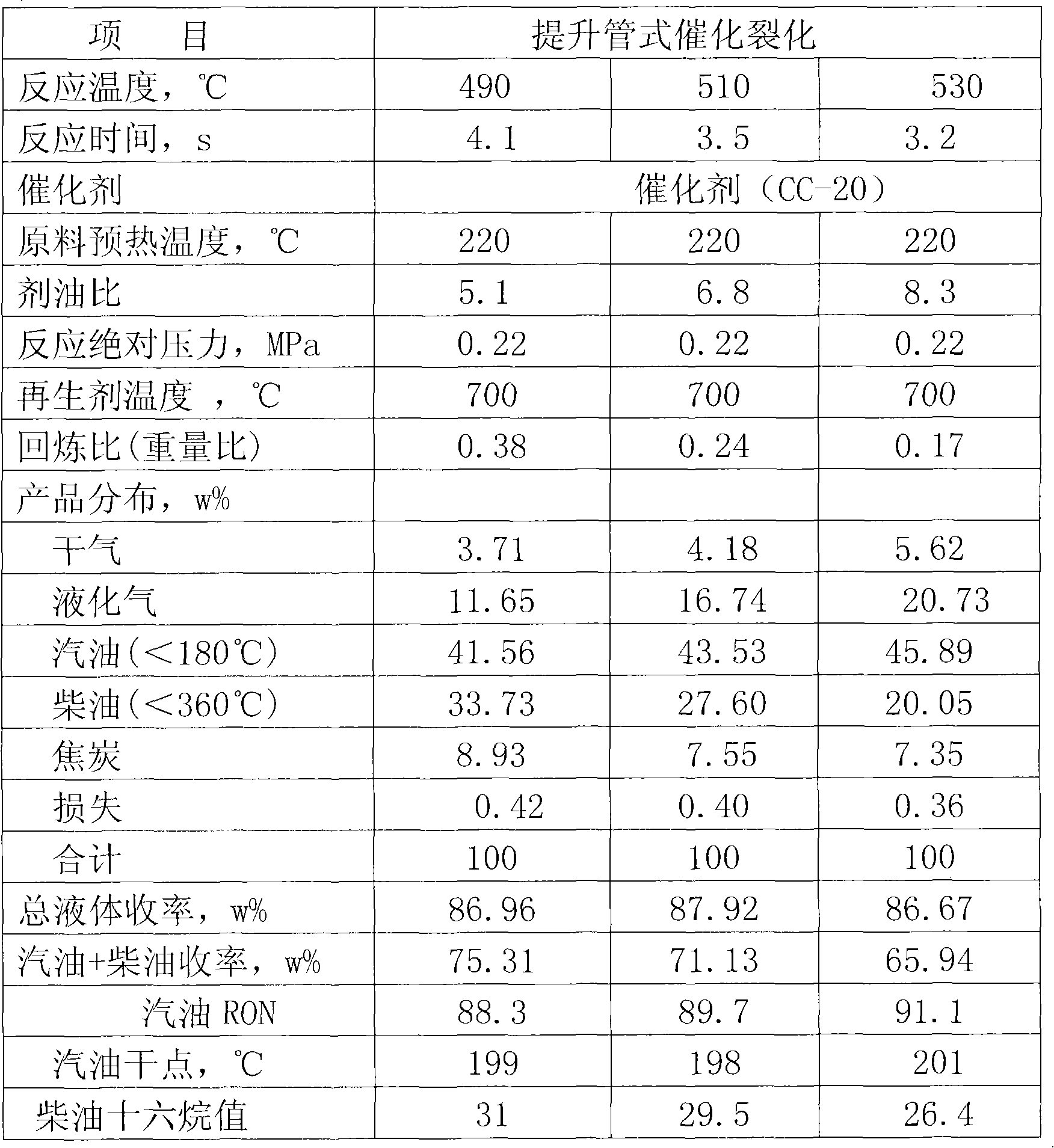

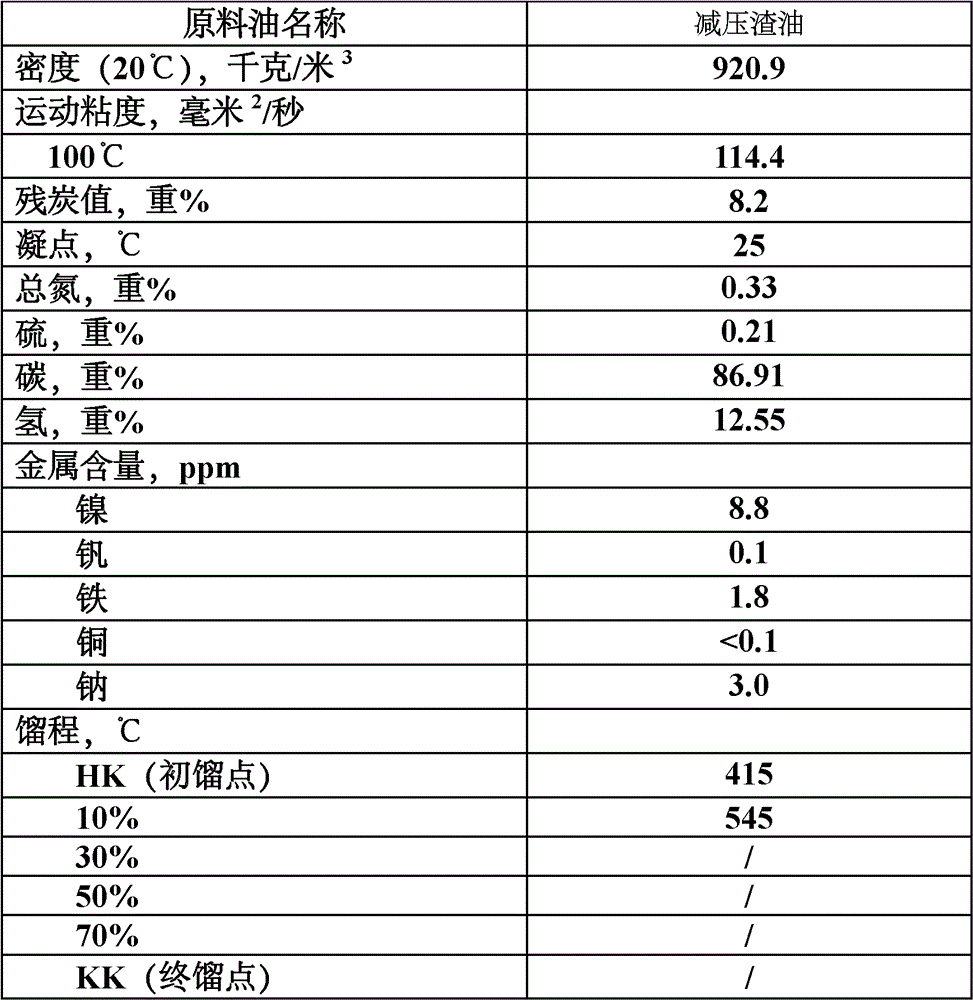

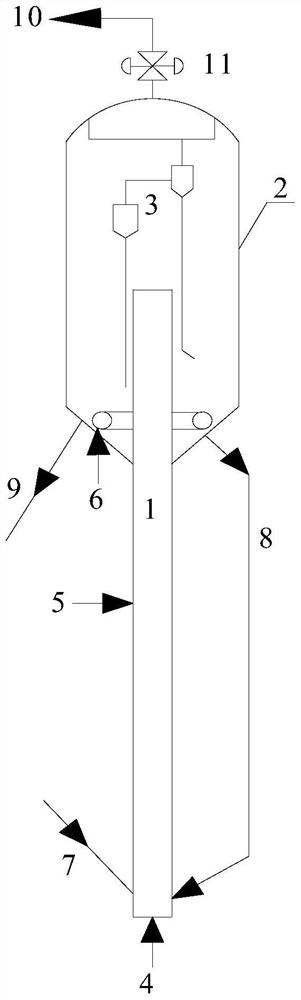

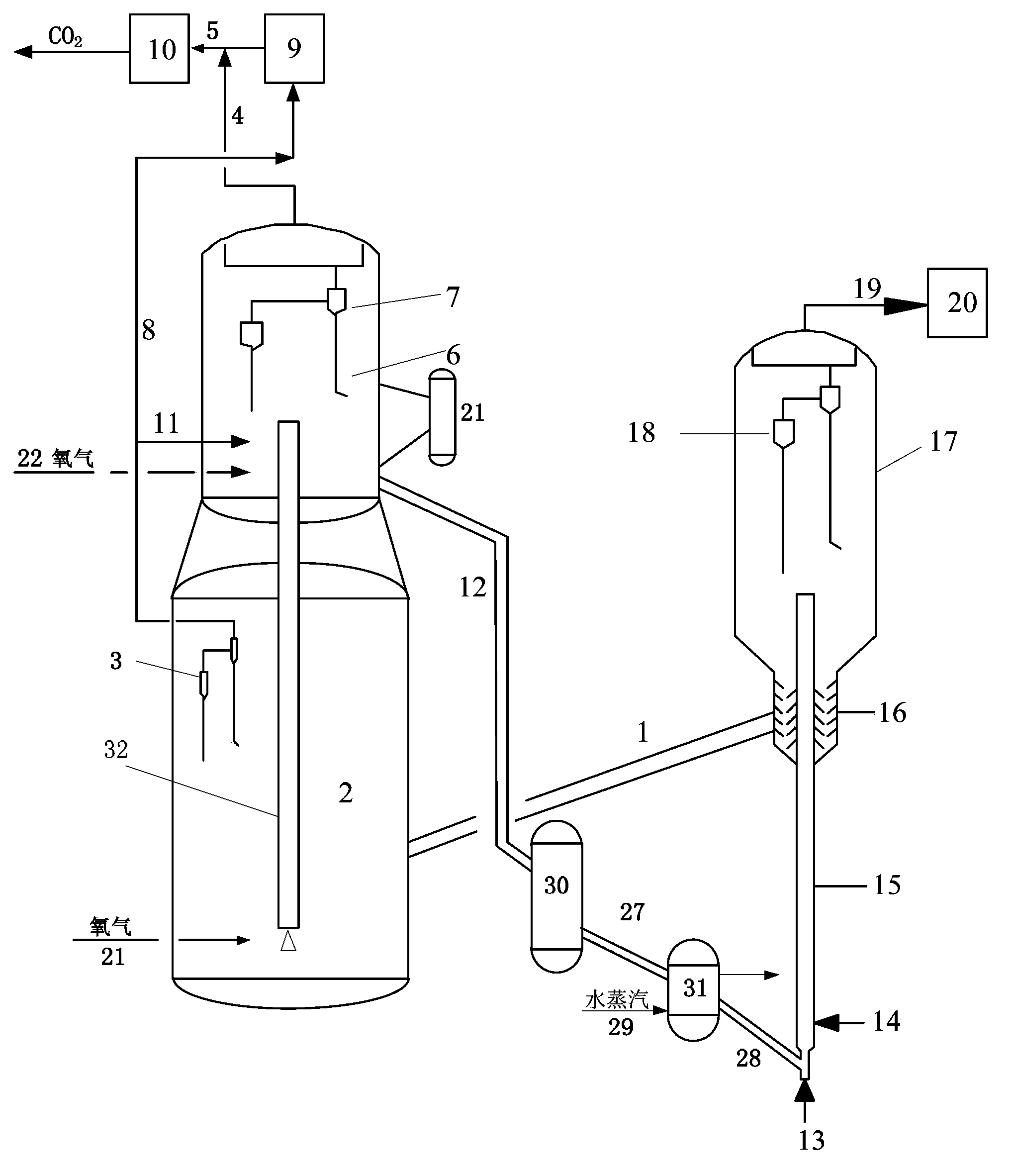

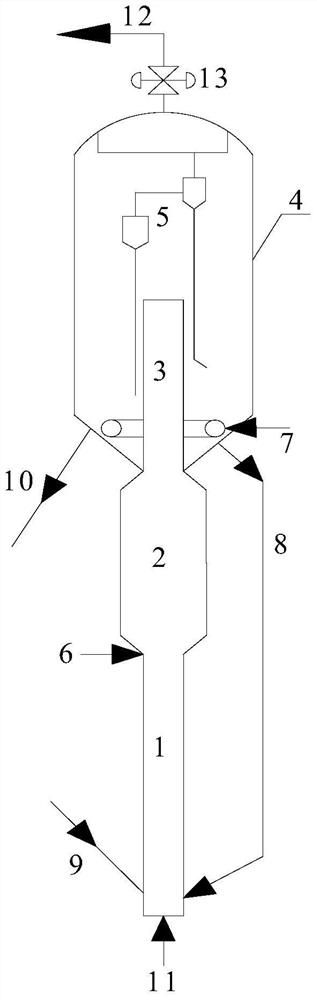

Catalytic cracking process and device

ActiveCN102212382AIncreased charring capacityIncreased char strengthCatalytic crackingFractionationGasoline

The invention discloses a catalytic cracking process and a catalytic cracking device. A main technical scheme is that: a regenerator is placed on the upper part of a reaction precipitator; a regenerated catalyst from the regenerator downwards enters the reaction precipitator to generate forward or backward contact reaction with raw oil entering the reaction precipitator through a feeding nozzle; after the reaction, the spent catalyst and the generated oil gas are subjected to separation and steam stripping; the generated oil gas subjected to separation and steam stripping enters a fractionating system to perform fractionation; the spent catalyst subjected to separation and steam stripping enters a tube type burning device to burn and regenerate; and the semi-regenerated catalyst regenerated by the tube type burning device enters a regenerator again to regenerate and then is recycled. By the catalytic cracking process and the catalytic cracking device, burning capacity can be enhanced and the treating quantity of raw materials is increased. The catalytic cracking process and the catalytic cracking device have the advantages of low contact temperature of the catalyst and the raw oil, short reaction time, big ratio of the catalyst to the oil, low yield of cracked gas and coke, high yield of gasoline and diesel, high product distributivity, simple device structure, operating flexibility, low energy consumption and the like.

Owner:CHINA PETROCHEMICAL CORP +1

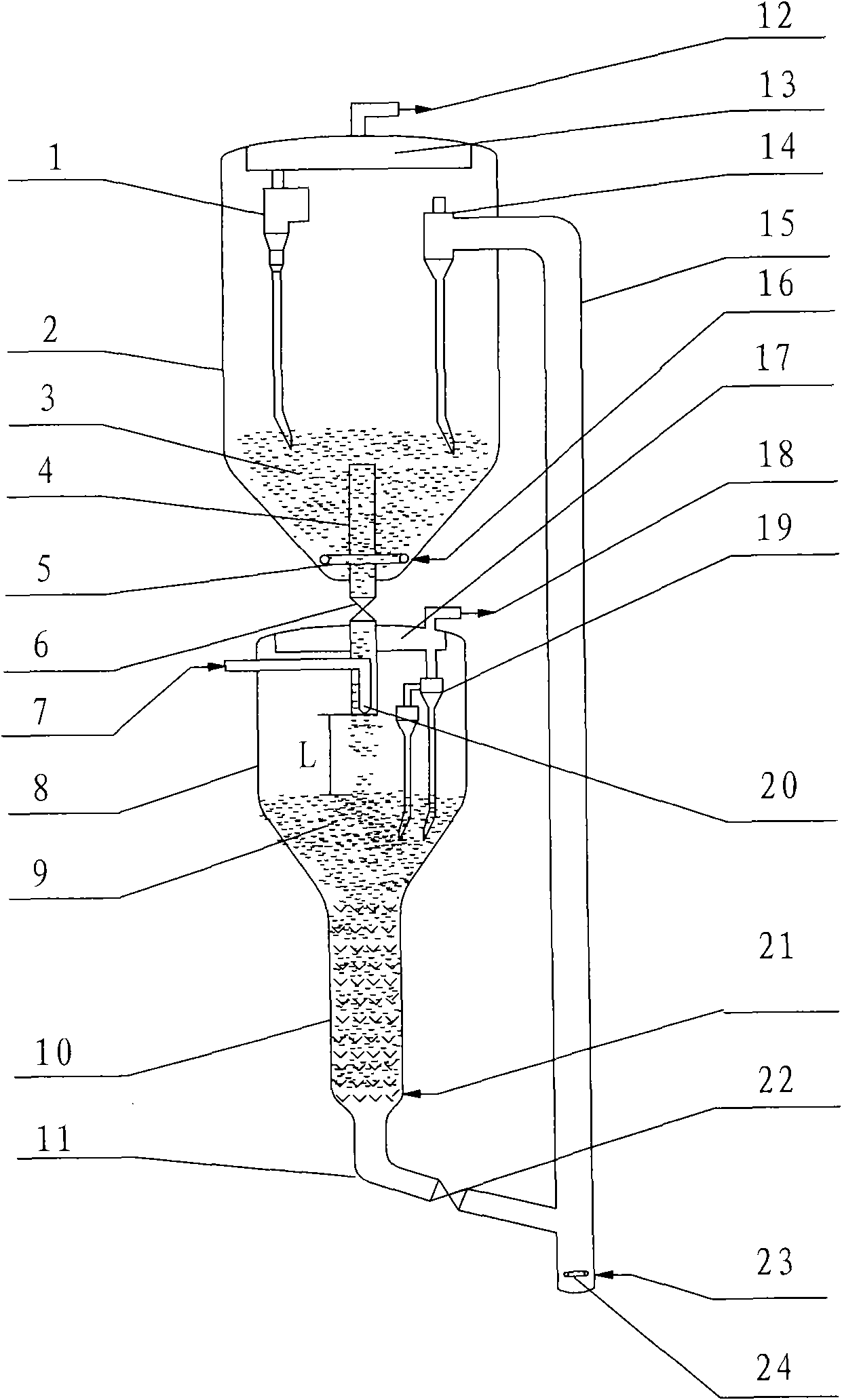

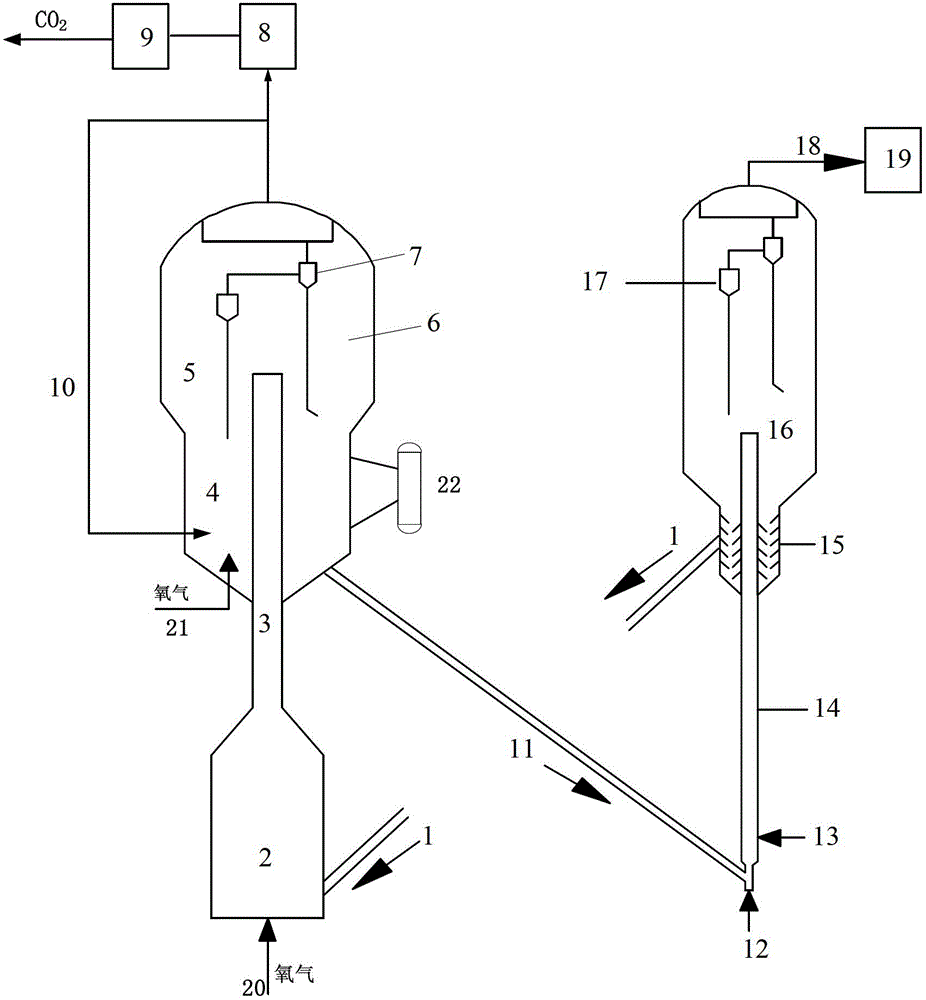

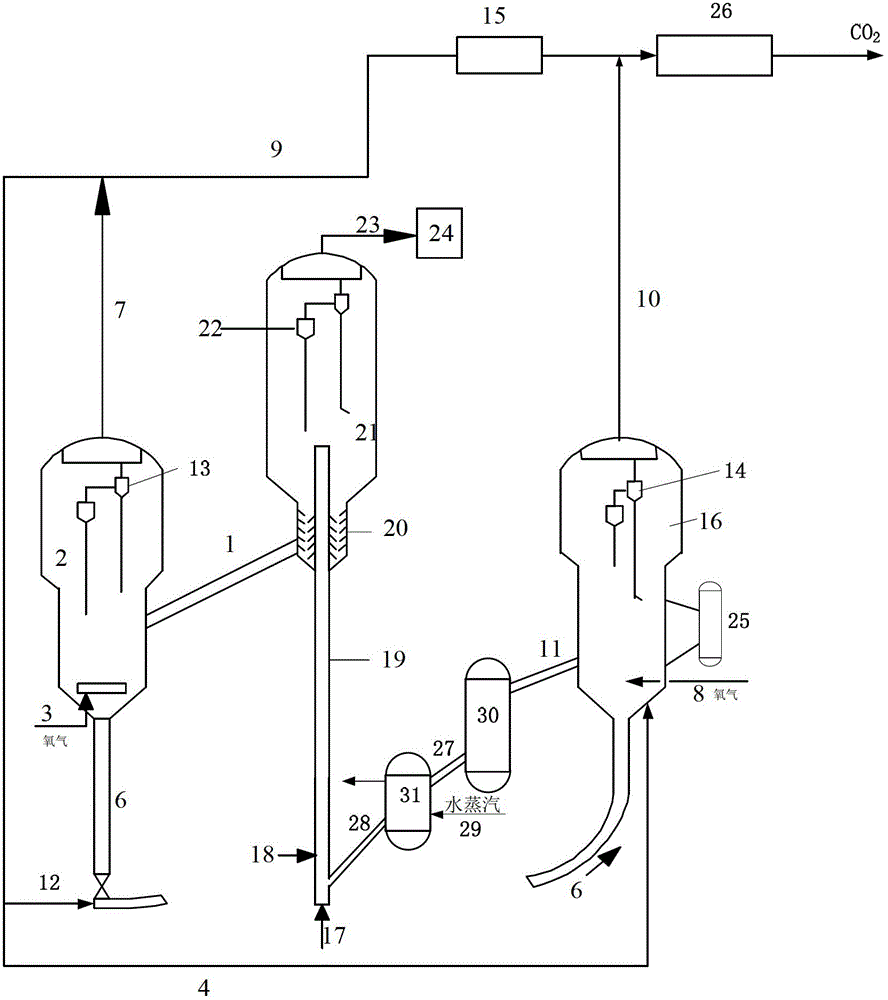

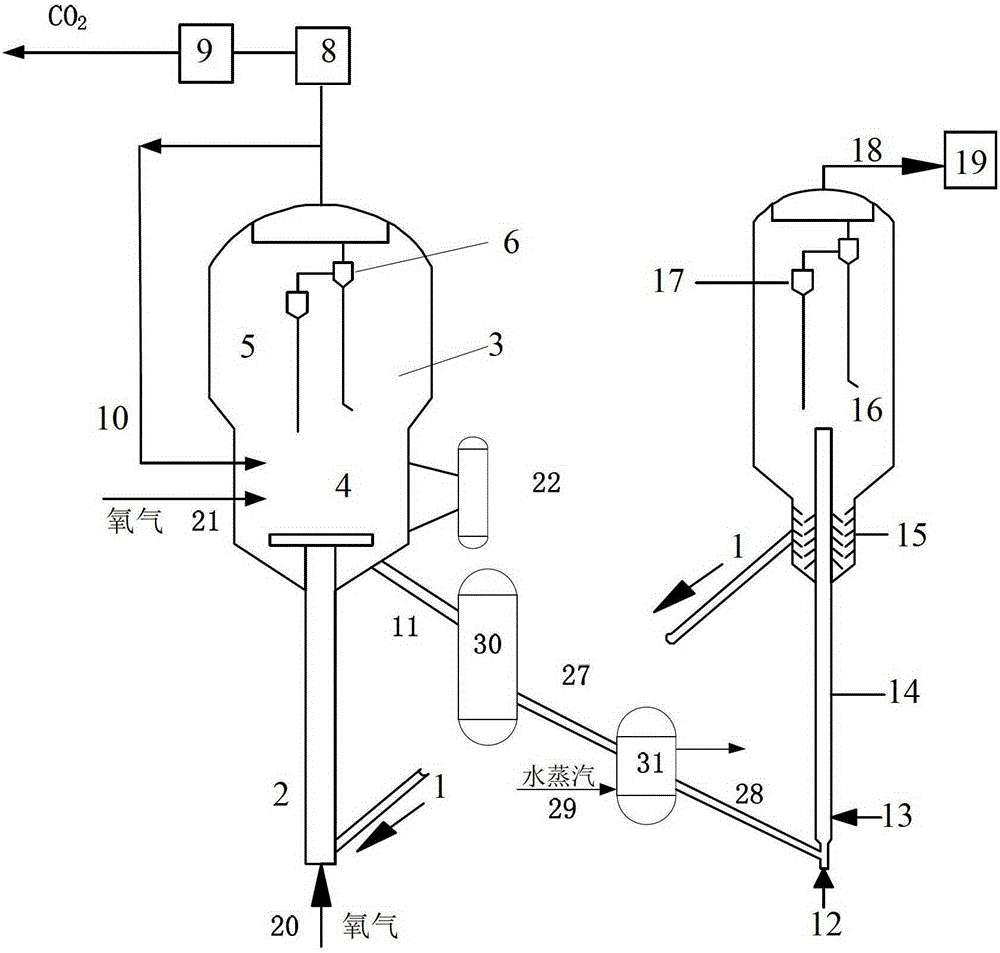

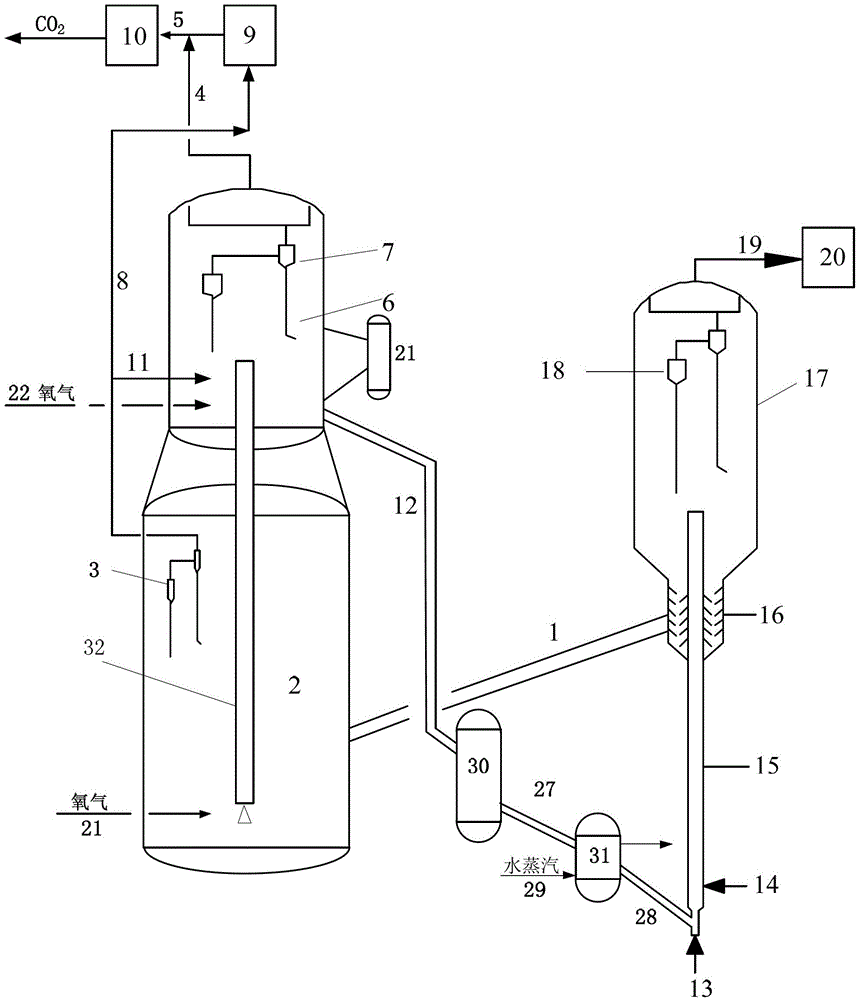

Catalyst regeneration method used for reducing carbon dioxide release and improving selectivity

ActiveCN103725311AEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionEnergy recoveryZero carbon

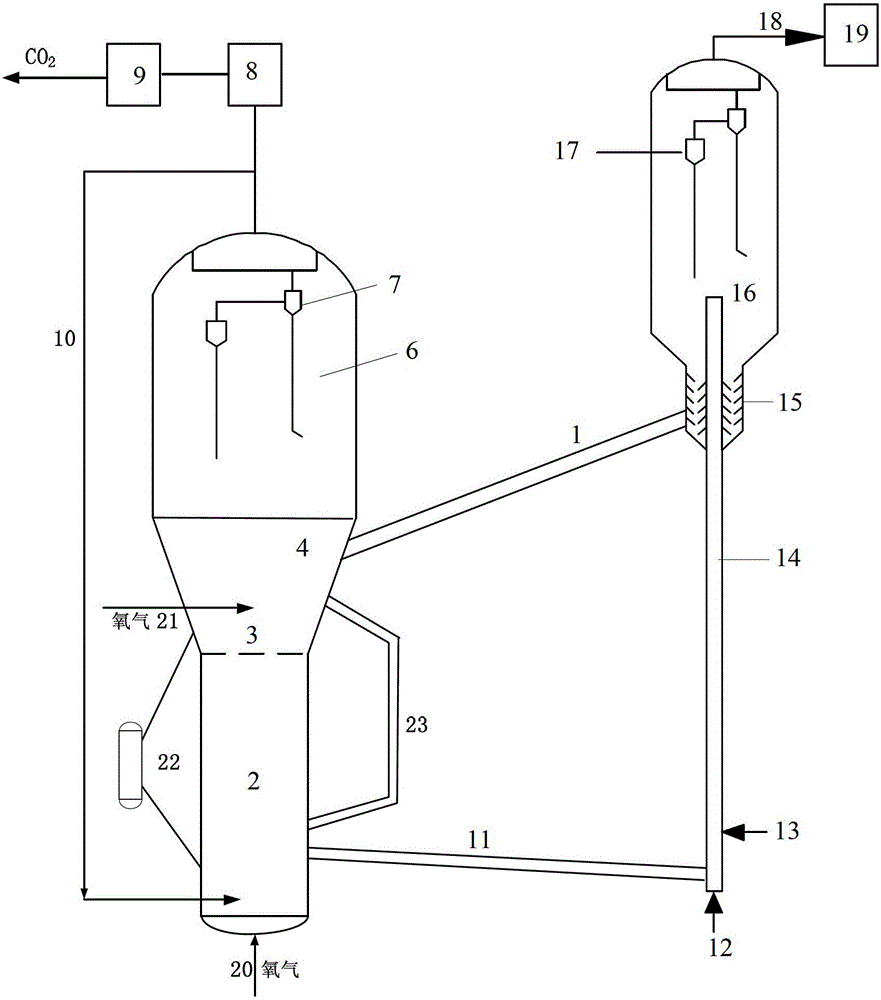

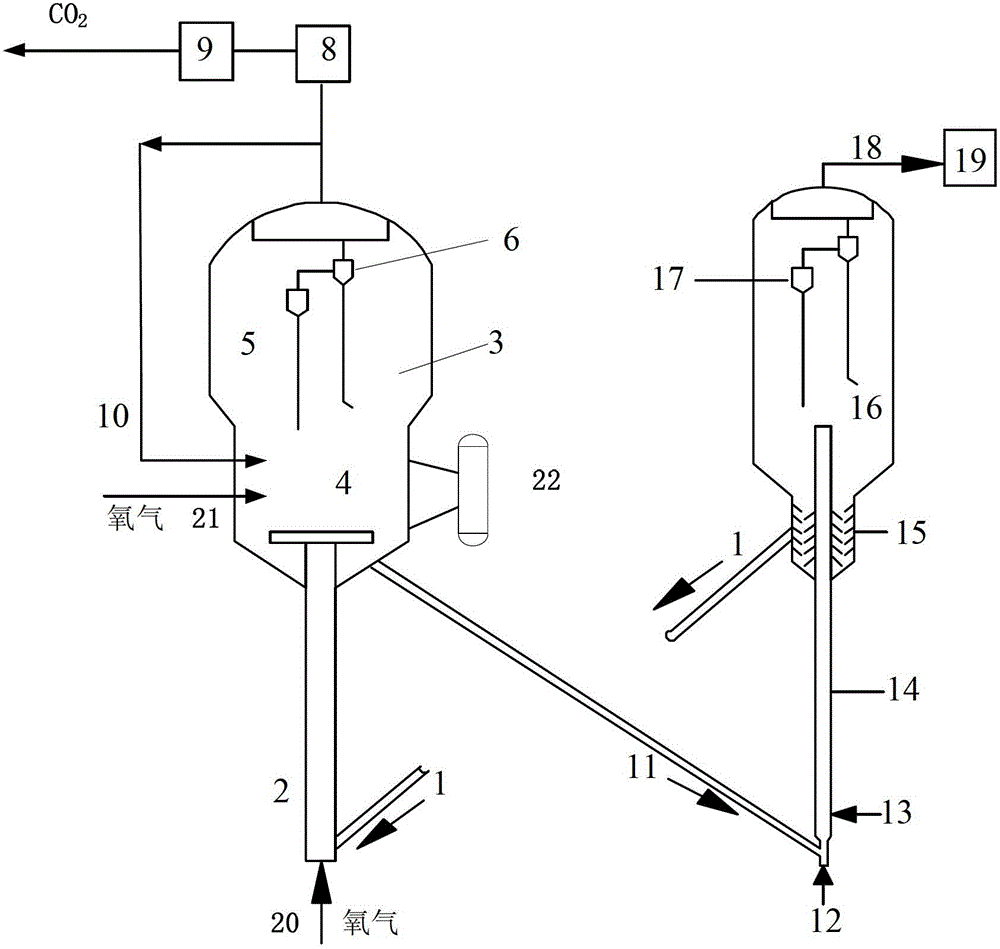

The invention discloses a catalyst regeneration method used for reducing carbon dioxide release and improving selectivity. The catalyst regeneration method comprises following steps: a carbon-containing catalyst is subjected to partial regeneration in a first regenerator using pure oxygen, and then is delivered into a second regenerator via a U-shaped delivery pipe so as to remove residual coke via combustion using pure oxygen, and smoke obtained from the first regenerator is divided into three parts, wherein a first part of the smoke is cycled into the bottom of the second regenerator, a second part is used for delivering the partially regenerated catalyst from the first regenerator into the second regenerator, and the third part is delivered into a smoke energy recovery system; smoke obtained from the second regenerator and the smoke which is obtained from the first regenerator and is processed via the smoke energy recovery system are combined, are delivered into a carbon dioxide separating system for carbon dioxide separation, and then are collected, and an obtained regenerated catalyst is cooled and activated using a catalyst, and is delivered into a reactor for recycling. The catalyst regeneration method is capable of realizing complete regeneration of the catalyst, reducing carbon release greatly, and even realizing zero carbon release. Catalyst activity distribution is more uniform, so that catalytic cracking product coke yield and dry gas yield are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity

ActiveCN103721761AEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a coke combustion tank, and the partially regenerated catalyst goes through a macroporous distribution plate, then is fed into a dense bed of a regenerator and then is subjected to residual coke burning; the dense bed is provided with a cooler for controlling a temperature of the dense bed; after cyclone separation, most of flue gas orderly enters into a flue gas energy recovery system and a carbon dioxide separation system, after carbon dioxide separation, a capturing process is carried out, and a small part of the flue gas is returned to the bottom of the coke combustion tank; and the regenerated catalyst is cooled and activated and then is fed into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method that reduces carbon dioxide emissions and improves selectivity

ActiveCN103721761BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationCyclonic separationEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a coke combustion tank, and the partially regenerated catalyst goes through a macroporous distribution plate, then is fed into a dense bed of a regenerator and then is subjected to residual coke burning; the dense bed is provided with a cooler for controlling a temperature of the dense bed; after cyclone separation, most of flue gas orderly enters into a flue gas energy recovery system and a carbon dioxide separation system, after carbon dioxide separation, a capturing process is carried out, and a small part of the flue gas is returned to the bottom of the coke combustion tank; and the regenerated catalyst is cooled and activated and then is fed into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method for reducing carbon dioxide emissions

ActiveCN103721743BEmission reductionReduce the greenhouse effectCatalytic crackingMolecular sieve catalystsCyclonic separationEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a coke combustion tank, and the partially regenerated catalyst goes through a macroporous distribution plate, then enters into a dense bed of a regenerator and then is subjected to residual coke burning; the dense bed is provided with a cooler for controlling a temperature of the dense bed; after cyclone separation, flue gas orderly enters into a flue gas energy recovery system and a carbon dioxide separation system and after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is directly returned into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method for reducing carbon dioxide emissions

ActiveCN103721765BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-used partial regeneration in a first regenerator; the partially regenerated catalyst goes through an external circulating pipe, then enters into a second regenerator below the first regenerator and then is subjected to pure oxygen-used residual coke burning; the catalyst discharged from the first regenerator is fed into an external cooler, then is cooled and then is returned to the second regenerator; after cyclone separation, flue gas orderly enters into a flue gas energy recovery system and a carbon dioxide separation system and after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is directly returned into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method to reduce carbon dioxide emissions and improve selectivity

ActiveCN103721766BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationEnergy recoveryNegative carbon dioxide emission

The invention discloses a catalyst regeneration method used for reducing carbon dioxide release and improving selectivity. The catalyst regeneration method comprises following steps: a carbon-containing catalyst is subjected to partial regeneration in a first regenerator using pure oxygen, and then is delivered into a second regenerator, which is arranged under the first regenerator, via an outer circulation pipe so as to remove residual coke via combustion using pure oxygen; the catalyst processed via the first regenerator is delivered into an outer heat supplying device, is cooled and is delivered back to the second regenerator; most smoke is subjected to cyclone separation, and then is delivered into a smoke energy recovery system, and a carbon dioxide separating system successively, and is collected after carbon dioxide separation, and a small amount of smoke is recycled to the bottom of the second regenerator; and an obtained regenerated catalyst is cooled and activated using a catalyst, and is delivered into a reactor for recycling. The catalyst regeneration method is capable of realizing complete regeneration of the catalyst, reducing carbon release greatly, and even realizing zero carbon release. Catalyst activity distribution is more uniform, so that catalytic cracking product coke yield and dry gas yield are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst regeneration method capable of reducing carbon dioxide discharge

ActiveCN103725308AEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge. The catalyst regeneration method is characterized in that a catalyst with coke goes up in a coke combustion pipe by being carried by pure oxygen and undergoes a coke combustion reaction, and the coke combustion ratio in a coke combustion pipe is in a range of 30-50%; the catalyst discharged from the coke combustion pipe is subjected to pure oxygen-based residual coke burning; after cyclone separation, flue gas is orderly fed into a flue gas energy recovery system and a carbon dioxide separation system; after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is directly returned into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking process and device

ActiveCN102212382BIncreased charring capacityIncreased char strengthCatalytic crackingGasolineFractionation

The invention discloses a catalytic cracking process and a catalytic cracking device. A main technical scheme is that: a regenerator is placed on the upper part of a reaction precipitator; a regenerated catalyst from the regenerator downwards enters the reaction precipitator to generate forward or backward contact reaction with raw oil entering the reaction precipitator through a feeding nozzle; after the reaction, the spent catalyst and the generated oil gas are subjected to separation and steam stripping; the generated oil gas subjected to separation and steam stripping enters a fractionating system to perform fractionation; the spent catalyst subjected to separation and steam stripping enters a tube type burning device to burn and regenerate; and the semi-regenerated catalyst regenerated by the tube type burning device enters a regenerator again to regenerate and then is recycled. By the catalytic cracking process and the catalytic cracking device, burning capacity can be enhanced and the treating quantity of raw materials is increased. The catalytic cracking process and the catalytic cracking device have the advantages of low contact temperature of the catalyst and the raw oil, short reaction time, big ratio of the catalyst to the oil, low yield of cracked gas and coke, high yield of gasoline and diesel, high product distributivity, simple device structure, operating flexibility, low energy consumption and the like.

Owner:CHINA PETROCHEMICAL CORP +1

A catalyst regeneration method for reducing carbon dioxide emissions

ActiveCN103725309BEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionEnergy recoveryNegative carbon dioxide emission

The invention discloses a catalyst regeneration method used for reducing carbon dioxide release. The catalyst regeneration method comprises following steps: a carbon-containing catalyst is subjected to partial regeneration in a charring tank using pure oxygen, and then is delivered into a dense phase bed layer of a regenerator via a dilute phase tube so as to remove residual coke via combustion, wherein the dense phase bed layer is provided with a heat supplying device so as to control temperature of the dense phase bed layer; smoke is subjected to cyclone separation, is successively delivered into a smoke energy recovery system, and a carbon dioxide separating system for carbon dioxide separation, and is collected; and an obtained regenerated catalyst is directly delivered back into a reactor for recycling. The catalyst regeneration method is capable of realizing complete regeneration of the catalyst, reducing carbon release greatly, and even realizing zero carbon release. Catalyst activity distribution is more uniform, so that catalytic cracking product coke yield and dry gas yield are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method for reducing carbon dioxide emissions

ActiveCN103725310BEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionEnergy recoveryNegative carbon dioxide emission

Owner:CHINA PETROLEUM & CHEM CORP +1

Coke-burning method for hydrocarbon conversion catalyst regeneration and structure of coke-burning area of regenerator

ActiveCN102218353BReduce the risk of burning out the inner screen due to overheatingThe overall thickness is thinCatalyst regeneration/reactivationOxygenMoving bed

The invention discloses a coke-burning method for hydrocarbon conversion catalyst regeneration and a structure of a coke-burning area of a regenerator. The invention solves the disadvantage of the temperature jump risk in a coke-burning area of a hydrocarbon conversion catalyst in the prior art. The method comprises the following steps: allowing a catalyst to be regenerated to enter a coke-burning area of a radial catalyst moving bed under gravity, allowing the catalyst to contact an oxygen-containing regenerating gas and burning out coke deposits on the catalyst, and allowing the catalyst to enter a chlorine oxidation area, wherein the coke-burning area of the catalyst moving bed comprises an inner screen and an outer screen; the lower diameter is larger than the upper diameter of the outer screen; the upper and the lower parts of the outer screen are connected by a conical structure; the outer screen with different diameters and the inner screen forms, from up to down, an upper quick-burning section, an intermediate transition section, and a lower overheating section of the coke-burning area; and the thickness ratio of the catalyst bed layers of the quick-burning section and the overheating section is 0.25-1, and the height ratio is 1-8.

Owner:CHINA PETROCHEMICAL CORP +1

A catalyst regeneration method that reduces carbon dioxide emissions and improves selectivity

ActiveCN103725311BEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionEnergy recoveryNegative carbon dioxide emission

The invention discloses a catalyst regeneration method used for reducing carbon dioxide release and improving selectivity. The catalyst regeneration method comprises following steps: a carbon-containing catalyst is subjected to partial regeneration in a first regenerator using pure oxygen, and then is delivered into a second regenerator via a U-shaped delivery pipe so as to remove residual coke via combustion using pure oxygen, and smoke obtained from the first regenerator is divided into three parts, wherein a first part of the smoke is cycled into the bottom of the second regenerator, a second part is used for delivering the partially regenerated catalyst from the first regenerator into the second regenerator, and the third part is delivered into a smoke energy recovery system; smoke obtained from the second regenerator and the smoke which is obtained from the first regenerator and is processed via the smoke energy recovery system are combined, are delivered into a carbon dioxide separating system for carbon dioxide separation, and then are collected, and an obtained regenerated catalyst is cooled and activated using a catalyst, and is delivered into a reactor for recycling. The catalyst regeneration method is capable of realizing complete regeneration of the catalyst, reducing carbon release greatly, and even realizing zero carbon release. Catalyst activity distribution is more uniform, so that catalytic cracking product coke yield and dry gas yield are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method for reducing carbon dioxide emissions

ActiveCN103725308BEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionFlue gasEnergy recovery

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst regeneration method used for reducing carbon dioxide release

ActiveCN103725310AEmission reductionReduce the greenhouse effectCatalytic crackingEthylene productionEnergy recoveryZero carbon

The invention discloses a catalyst regeneration method used for reducing carbon dioxide release. The catalyst regeneration method comprises following steps: a carbon-containing catalyst is subjected to partial regeneration in a first regenerator using pure oxygen, and then is delivered into a second regenerator via a U-shaped delivery pipe so as to remove residual coke via combustion using pure oxygen, and smoke obtained from the first regenerator is divided into three parts, wherein a first part of the smoke is cycled into the bottom of the second regenerator, a second part is used for delivering the partially regenerated catalyst from the first regenerator into the second regenerator, and the third part is delivered into a smoke energy recovery system; smoke obtained from the second regenerator and the smoke which is obtained from the first regenerator and is processed via the smoke energy recovery system are combined, are delivered into a carbon dioxide separating system for carbon dioxide separation, and then are collected, and an obtained regenerated catalyst is directly delivered back into a reactor for recycling. The catalyst regeneration method is capable of realizing complete regeneration of the catalyst, reducing carbon release greatly, and even realizing zero carbon release. Catalyst activity distribution is more uniform, so that catalytic cracking product coke yield and dry gas yield are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidised bed gas and solid contacting device

ActiveCN100460050CReduce carbon contentReduce dosageChemical/physical processesGas solidFluidized bed

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

A kind of regeneration method of coking catalyst

ActiveCN107262162BSolve the problem of burning and burningFast regenerationCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFlue gas

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity

ActiveCN103721764AEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a first regenerator, and the partially regenerated catalyst goes through a lifting pipe, then is fed into a second regenerator above the first regenerator and then is subjected to pure oxygen-based residual coke burning; flue gas discharged from the first regenerator is divided into two parts, one of the two parts is circularly supplied to the bottom of the second regenerator and the other part of the two parts is fed into a flue gas energy recovery system; flue gas discharged from the second regenerator and the first regenerator flue gas discharged from the flue gas energy recovery system are mixed and the mixed flue gas is fed into a carbon dioxide separation system; after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is cooled and activated and then is fed into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method that reduces carbon dioxide emissions and improves selectivity

ActiveCN103721763BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention relates to a catalyst regeneration method able to reduce carbon dioxide emission and improve selectivity. The method includes: letting a char-containing catalyst move upward in a charring pipe under carrying by a pure oxygen gas to undergo coke combustion reaction, keeping the charring ratio in the charring pipe at 30-50%, making the catalyst coming from the charring pipe burn up the residual coke through pure oxygen, subjecting the flue gas to cyclone separation, then letting the separated flue gas enter a flue gas energy recovery system and a carbon dioxide separation system, separating carbon dioxide and then performing capturing, subjecting the regenerated catalyst to cooling and activation, then leading the regenerated catalyst into a reactor to undergo recycling. The method not only can make the catalyst regenerate completely and make the catalyst activity distribution more uniform so as to reduce the catalytic cracking by-product coke and dry gas yields, but also can greatly reduce carbon emission, or even reach zero carbon emission.

Owner:CHINA PETROLEUM & CHEM CORP +1

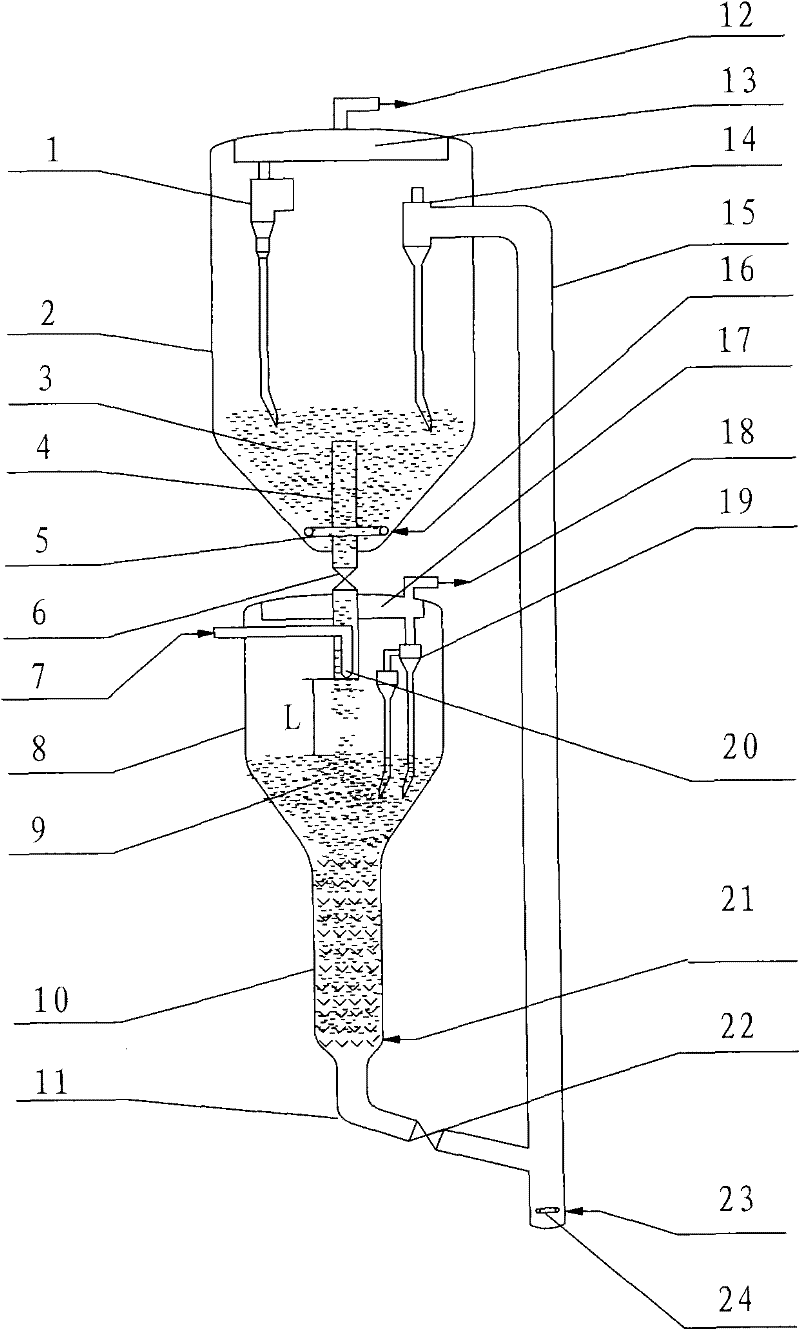

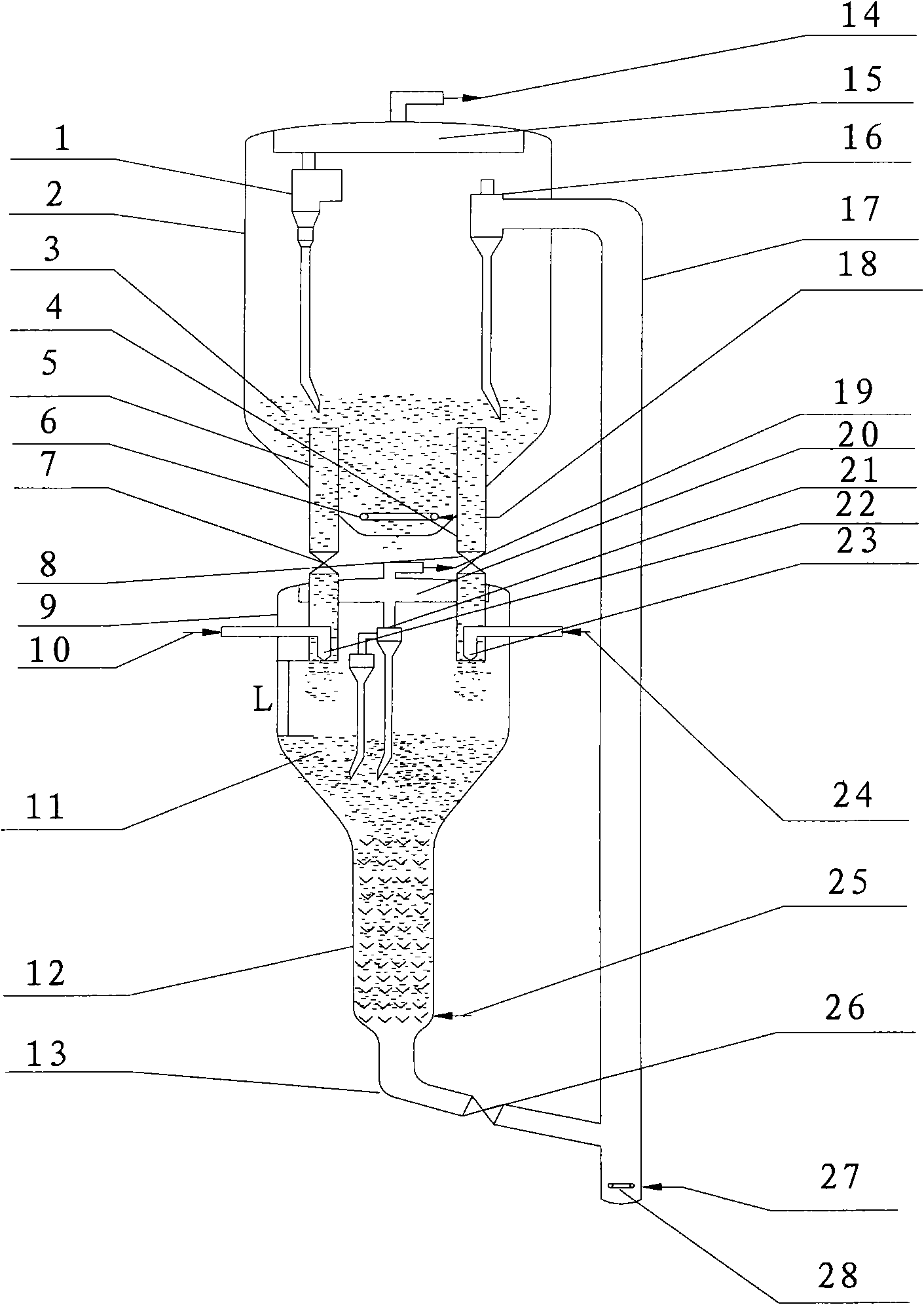

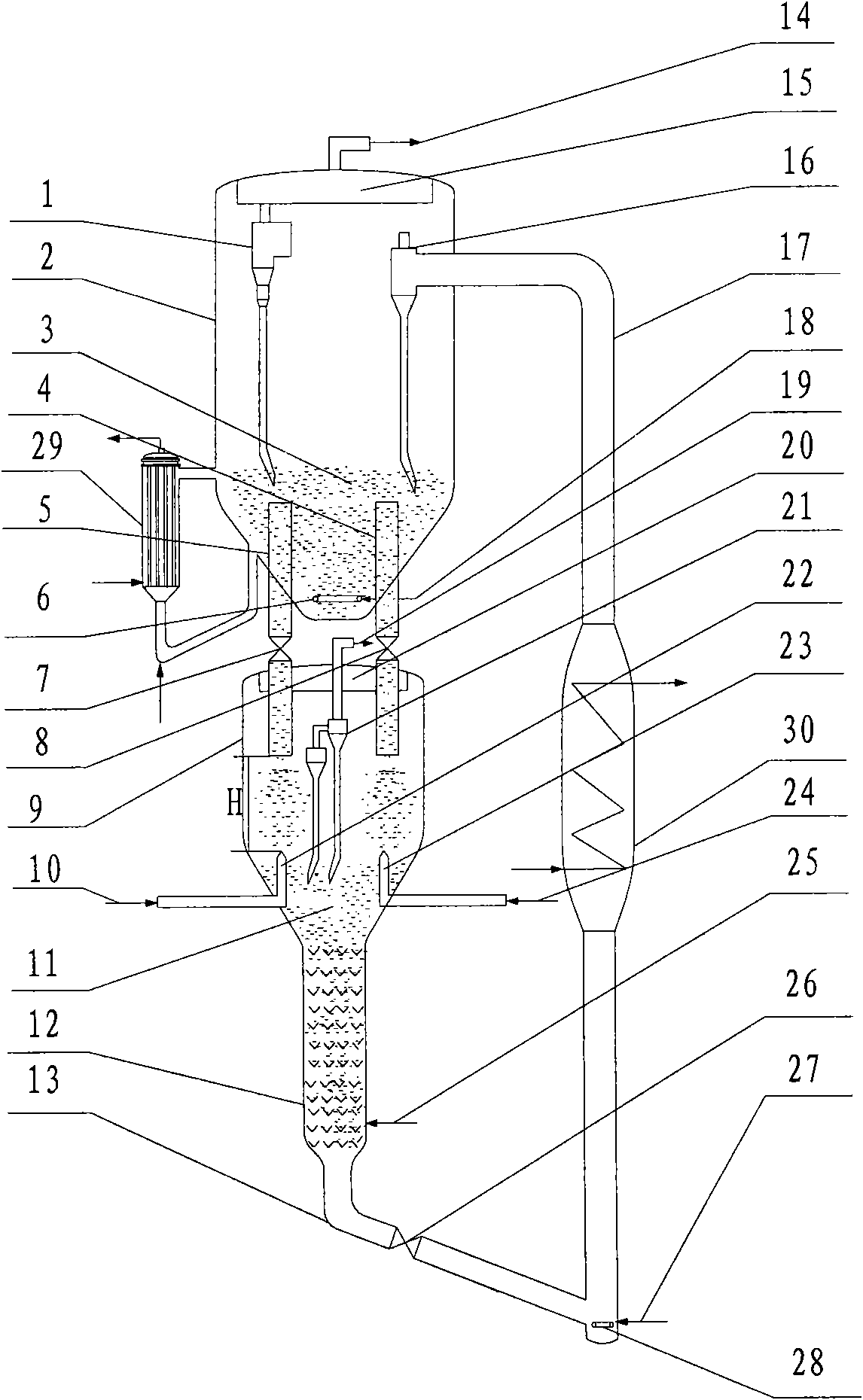

A method and system for regenerating a coked catalyst

ActiveCN107262161BSolve the problem of burning and burningFast regenerationCatalytic crackingCatalyst regeneration/reactivationThermodynamicsPtru catalyst

The invention discloses a regeneration method and system for a coking catalyst. The method comprises the steps as follows: the coking catalyst is sent into a riser regenerator from the bottom of the riser regenerator to be alternately contacted with at least one stream of oxygen-rich gas and at least one stream of oxygen-containing gas from bottom to top and regenerated, and a regenerated catalyst is obtained; the riser regenerator is provided with at least one regeneration section comprising a thin pipe section and a thick pipe section, the thick pipe section in the regeneration section is located above the thin pipe section, the oxygen-rich gas is sent into the riser regenerator from the lower part of the thin pipe section, and the oxygen-containing gas is sent into the riser regenerator from the lower part of the thick pipe section; the oxygen volume content of the oxygen-rich gas is larger than 21vol%, and the oxygen-containing gas is selected from at least one of oxygen, air and flue gas. With the adoption of the method adopting the system, the coking efficiency can be substantially improved, the catalytic cracking selection of the regenerated catalyst can be improved, and the size of the regenerator can be reduced in the same catalyst treatment quantity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking technology and device for reducing olefins in gasoline

ActiveCN102268291BIncreased charring capacityIncreased char strengthCatalytic crackingTreatment with plural serial stages onlyFlue gasFractionation

The invention discloses a catalytic cracking technology and a device for reducing olefins in gasoline. The catalytic cracking technology comprises the following steps that a regenerated catalyst is divided into two groups and the two groups are fed into a reaction sedimentation device and undergo contact reactions respectively with heavy feedstock and inferior gasoline feedstock; reaction productflows obtained from the previous step are separated; the separated reaction product oil gas is fed into a fractionation system to be fractionated and the separated catalyst needing to be regenerated is fed into a tube-type burning device to be subjected to burning regeneration; the regenerated catalyst obtained by the previous step is fed into a cyclone separator in a regenerator to be subjected to separation of the regenerated catalyst from flue gas; then the separated flue gas is discharged from the regenerator and the separated semi-regenerated catalyst is fed into a regenerator catalyst dense bed to be subjected to burning regeneration; and the regenerated catalyst obtained by the previous step is recycled.

Owner:CHINA PETROCHEMICAL CORP +1

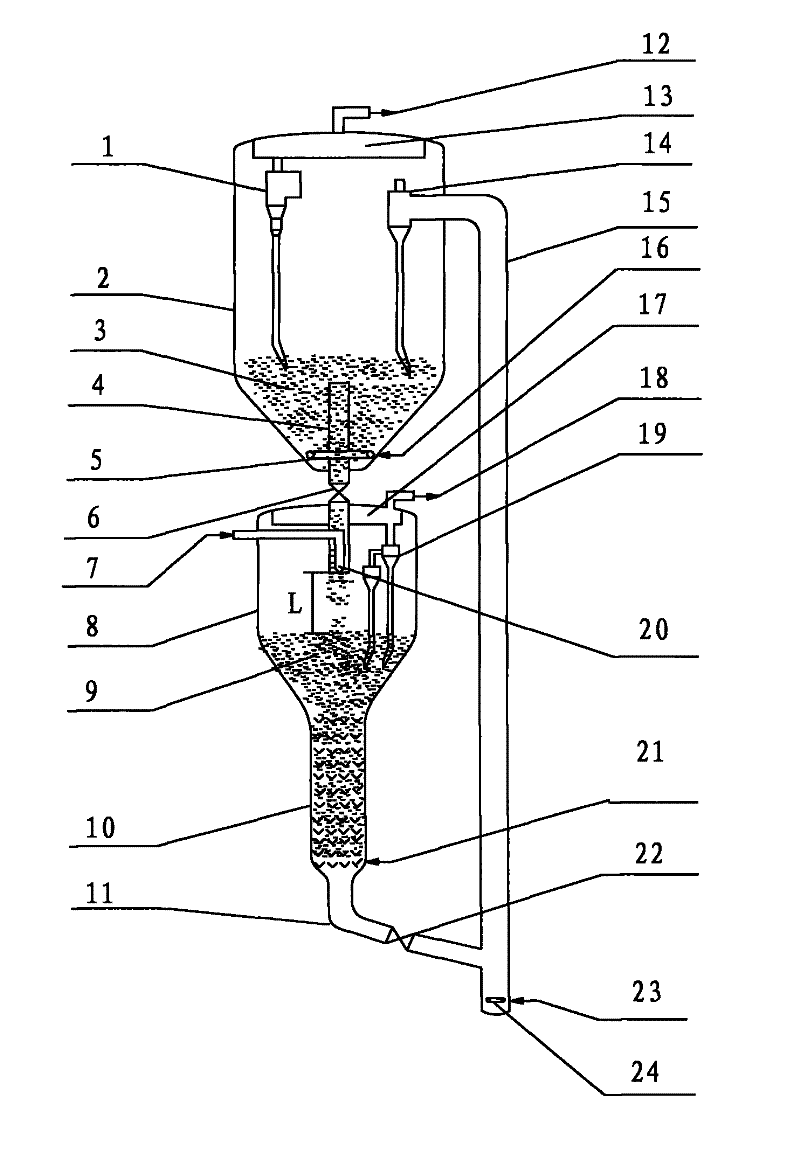

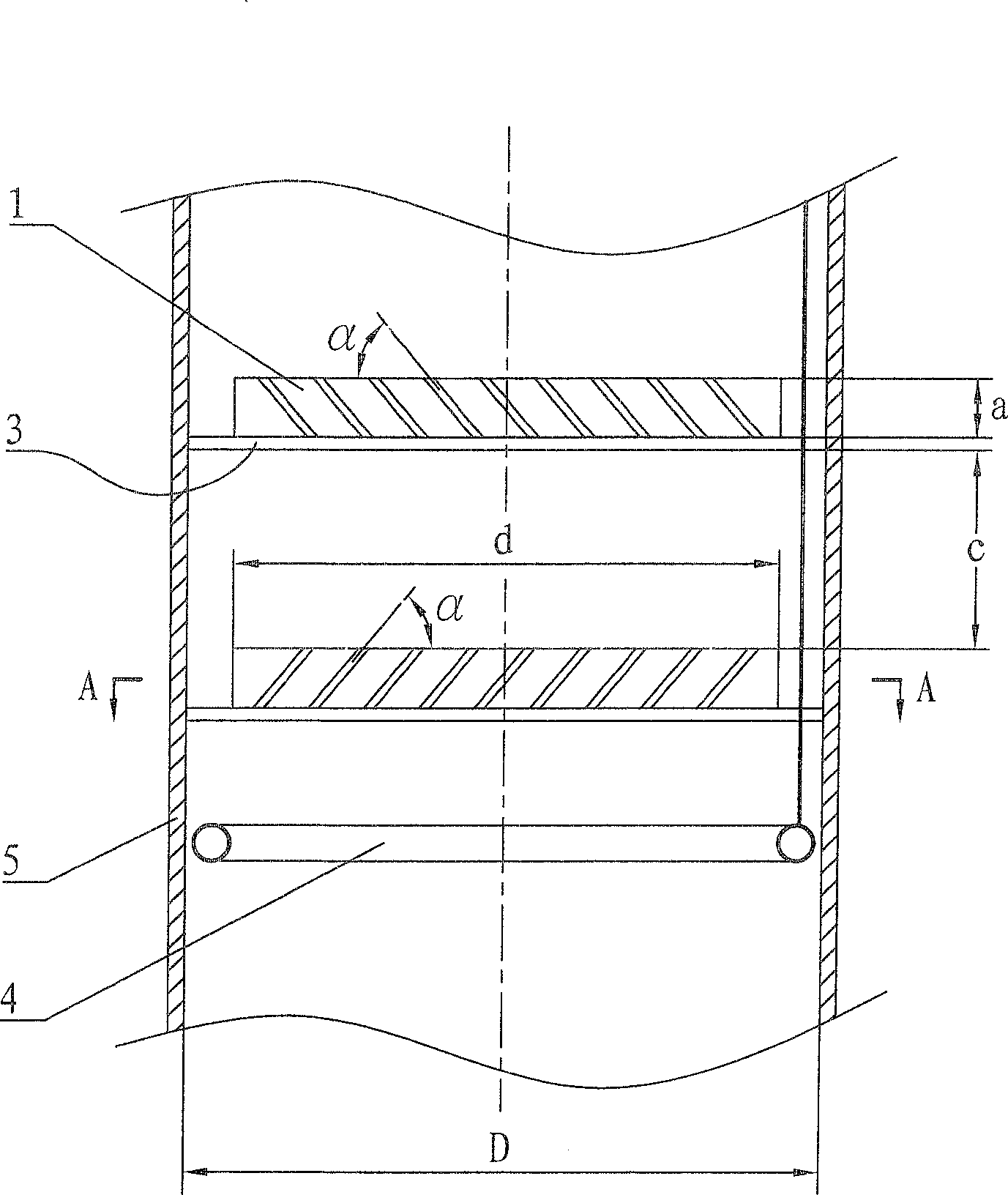

Fluidised bed gas-solid contacting device

ActiveCN100490963CImprove stripping efficiencyImprove efficiencyChemical/physical processesGas solidFluidized bed

The invention discloses a fluidized bed gas-solid contacting device for the petrochemical processing catalytic conversion equipment, to resolve the problem of the existing device that the installation, maintain and maintenance is difficult and the stripping efficiency is low. The contacting device is mounted at least with two groups of filler layers along the axial of tunnel body (5), and the there is gap between the adjacent filler layers. Each group of filler layers is mounted with a filler layer (1) with ramp way, and supported on the support rack (3). The filler layer (1) with ramp way is composed of two rows of stripe boards which acclivitous to the horizontal plane and is intercrossed, the two rows of intercrossed stripe boards forms the ramp way which is acclivitous to the horizontal plane. The preferred plan of the invention is that the filler layer with erective channels is mounted under the filler layer with ramp way in each group of the filler layers. The invention can be used as a steam stripping machine to steam strip the oil gas, hydrocarbon compound or gas impurities in the catalyst, and also used as a regenerator for the regeneration of catalyst.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Hydrocarbon conversion catalyst regeneration burning method and regenerator burning area structure

ActiveCN102218354BReduce the risk of burning out the inner screen due to overheatingThe overall thickness is thinCatalytic naphtha reformingCatalyst regeneration/reactivationPolymer scienceProduct gas

The invention discloses a hydrocarbon conversion catalyst regeneration burning method and a regenerator burning area structure, and solves the problems that a hydrocarbon conversion catalyst burning area has a temperature runaway risk and the like in the prior art. The method comprises the following steps of: introducing a catalyst to be regenerated into a radial catalyst moving bed burning area by means of gravity, contacting oxygen-containing regeneration gas, and burning carbon deposit on the catalyst; and introducing into a chlorine oxidation area under the action of gravity, wherein a catalyst moving bed in the burning area is provided with a quick firing section, a transition section and a superheat section from top to bottom in turn; and the thickness ratio of catalyst beds in the quick firing section and the superheat section is 0.25-1 and the height ratio is 1-8.

Owner:CHINA PETROCHEMICAL CORP +1

A catalyst regeneration method that reduces carbon dioxide emissions and improves selectivity

ActiveCN103721764BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a first regenerator, and the partially regenerated catalyst goes through a lifting pipe, then is fed into a second regenerator above the first regenerator and then is subjected to pure oxygen-based residual coke burning; flue gas discharged from the first regenerator is divided into two parts, one of the two parts is circularly supplied to the bottom of the second regenerator and the other part of the two parts is fed into a flue gas energy recovery system; flue gas discharged from the second regenerator and the first regenerator flue gas discharged from the flue gas energy recovery system are mixed and the mixed flue gas is fed into a carbon dioxide separation system; after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is cooled and activated and then is fed into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst regeneration method to reduce carbon dioxide emissions and improve selectivity

ActiveCN103721762BEmission reductionReduce the greenhouse effectMolecular sieve catalystsCatalyst regeneration/reactivationFlue gasEnergy recovery

The invention discloses a catalyst regeneration method capable of reducing carbon dioxide discharge and improving selectivity. The catalyst regeneration method is characterized in that a catalyst with coke is subjected to pure oxygen-based partial regeneration in a coke combustion tank, and the partially regenerated catalyst goes through a dilute phase tube, then enters into a dense bed of a regenerator and then is subjected to residual coke burning; the dense bed is provided with a cooler for controlling a temperature of the dense bed; after cyclone separation, flue gas orderly enters into a flue gas energy recovery system and a carbon dioxide separation system; after carbon dioxide separation, a capturing process is carried out; and the regenerated catalyst is cooled and activated and then is fed into a reactor for recycle. The catalyst regeneration method realizes complete regeneration of a catalyst and uniform distribution of catalyst activity so that coke as a catalytic cracking by-product and a dry gas yield are reduced. The catalyst regeneration method greatly reduces carbon emission and even realizes zero emission of carbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com