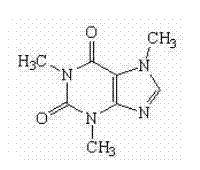

Methods for preparing high-hydrophilcity macroporous absorption resin and removing caffeine in crude tea extracts

A technology of pore adsorption and caffeine, which is applied in the field of high-purity tea polyphenol extracts, can solve the problems of low resin adsorption capacity, complicated process operation, and large difference in reactivity ratio, etc., and is suitable for large-scale industrial production, The removal process is simple to operate and the effect of improving the adsorption selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of Highly Hydrophilic Alcohol Hydroxyl Macroporous Adsorption Resin

[0023] Add 425mL of 0.5% gelatin aqueous solution into a 1000mL three-necked bottle at room temperature, and heat to 40°C. Mix 28g TAIC, 56g VAc, 84g n-heptane, and 0.84g AIBN evenly, pour it into a three-necked flask, start stirring and slowly raise the temperature to 60°C at a heating rate of 0.5°C / min, react for 5 hours, and then raise the temperature to 80°C , reacted for 6 hours, stopped stirring and heating, let it stand to room temperature, filtered out the resin, washed it with a large amount of deionized water, and dried it in vacuum.

[0024] Add 60g of the above-mentioned dry resin into a 500mL three-necked flask, add 250g of sodium hydroxide aqueous solution with a mass percentage concentration of 5%, start stirring, raise the temperature to 50°C, and react for 5 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large ...

Embodiment 2

[0025] Example 2 : Preparation of Highly Hydrophilic Alcoholic Hydroxyl Macroporous Adsorbent Resin

[0026] Add 900mL of 1% gelatin aqueous solution into a 2000mL three-necked bottle at room temperature, and heat to 45°C. Mix 40g TAIC, 160g VAc, 100g n-octane, and 1.5g AIBN evenly, pour it into a three-necked flask, start stirring and slowly raise the temperature to 70°C at a heating rate of 0.2°C / min, react for 8 hours, and then raise the temperature to 90°C , reacted for 4 hours, stopped stirring and heating, let stand to room temperature, filtered out the resin, washed with a large amount of deionized water, and dried in vacuum.

[0027] Add 150g of the above-mentioned dried resin into a 1000mL three-necked flask, add 750g of sodium hydroxide aqueous solution with a mass percentage concentration of 10%, start stirring, raise the temperature to 60°C, and react for 2 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large am...

Embodiment 3

[0028] Example 3: Preparation of Highly Hydrophilic Alcohol Hydroxyl Macroporous Adsorption Resin

[0029] Add 1200mL of 0.5% gelatin aqueous solution into a 3000mL three-necked bottle at room temperature, and heat to 50°C. Mix 80g TAIC, 80g VAc, 240g dodecane, and 1.0g AIBN evenly, pour it into a three-necked bottle, start stirring and slowly raise the temperature to 62°C at a heating rate of 0.4°C / min, react for 6 hours, and then raise the temperature to 87°C , reacted for 4 hours, stopped stirring and heating, let stand to room temperature, filtered out the resin, washed with a large amount of deionized water, and dried in vacuum.

[0030] Add 120g of the above-mentioned dried resin into a 1000mL three-necked flask, add 540g of sodium hydroxide aqueous solution with a concentration of 7% by mass, start stirring, raise the temperature to 55°C, and react for 4 hours, stop stirring and heating, and let it stand at room temperature. Filter out, wash with a large amount of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com