Production method for high-purity hard-agglomeration-free superfine nickel oxide or cobalt and nickel or cobalt powder

A production method and technology of nickel oxide, which is applied in the chemical industry, can solve the problems of low yield, easy sintering of powder, and low production efficiency, and achieve the effects of reducing costs, reducing environmental pollution, and improving quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

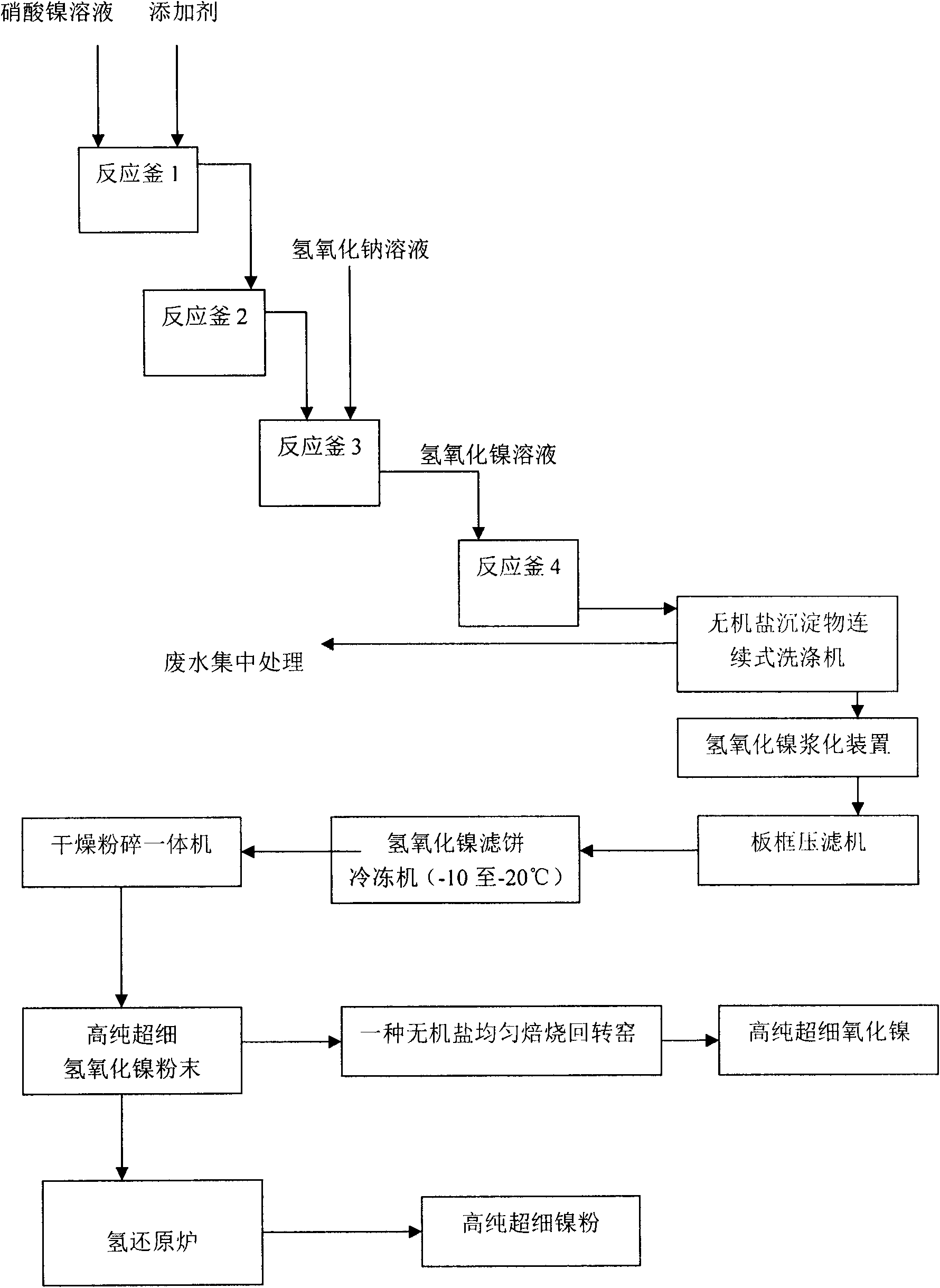

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 high-purity nickel nitrate or cobalt solution preparation

[0042] With metal nickel or cobalt and nitric acid solution, it is produced by the reaction equipment of the Chinese patent "Exhaust gas absorption device for producing nitrate", CN201410354, and realizes pollution-free and environmentally friendly production of nickel nitrate or cobalt solution; concentration is 50-190g / L nitric acid For nickel solution, use P204 to extract copper, lead, zinc, manganese and other metal impurities, P507 to remove impurities, or use P204 to extract cobalt nitrate solution to obtain high-purity nickel nitrate or cobalt solution.

Embodiment 2

[0043] Embodiment 2 The production method of high-purity non-hard agglomeration superfine nickel or cobalt powder and nickel oxide or cobalt

[0044]1) Heat 60g-100g / L high-purity nickel nitrate or cobalt solution to 80-100°C and add it to the reaction kettle, 3 L nickel nitrate or cobalt solution, add 14-16 kilograms of additive A, stir evenly, described additive A is by the volume 1: 1: 1 ratio of acetone, hexylene glycol, alcohol, temperature 50-100 ℃ of preparations;

[0045] 2) Add 7-10g / L additive B again, the addition amount is 2 times of the volume of nickel nitrate or cobalt solution, described additive B is to be prepared by 1:1:1 ratio by weight of urea, ammonium carbonate, ammonia water, ammonia water The concentration is 20-25%, stirring while adding, the addition is completed in 40-60 minutes, and the temperature of the reactor is kept at 80-100°C;

[0046] 3) Then add 40-60g / L sodium hydroxide solution of the same volume as the addition of B, stir while adding,...

Embodiment 3

[0051] Embodiment 3 The production method of high-purity non-hard agglomeration superfine nickel or cobalt powder or nickel oxide or cobalt

[0052] 1) Heat 70g-80g / L high-purity nickel nitrate or cobalt solution to 80-100°C and add it to the reaction kettle, 3 L nickel nitrate or cobalt solution, add 14-15 kilograms of additive A, stir evenly, described additive A is by the volume 1: 1: 1 ratio of acetone, hexanediol, alcohol, temperature 50-100 ℃ of preparations;

[0053] 2) Add 7-8g / L additive B again, the addition amount is 2 times of the volume of nickel nitrate or cobalt solution, described additive B is to be prepared by the ratio of 1: 1: 1 by weight of urea, ammonium carbonate, ammonia water, ammonia water The concentration is 20-25%, stirring while adding, the addition is completed in 40-60 minutes, and the temperature of the reactor is kept at 80-100°C;

[0054] 3) Then add 40-60g / L sodium hydroxide solution of the same volume as the addition of B, stir while addin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com