Method for preparing titanium-zirconium/polyhydroxy esterified product composite conversion coating of aluminum alloy surface

An aluminum alloy surface, polyhydroxyl technology, applied in the direction of metal material coating process, can solve problems such as unfavorable observation, corrosion resistance to be improved, complex process, etc., to achieve industrial application, good film-forming performance, process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of polyhydroxy ester compound a:

[0061] 24g of gallic acid, 50g of ethylene glycol, 0.2g of p-toluenesulfonic acid, and 10g of xylene were added to a four-necked round-bottomed flask with a stirring rod, a condensation device and a water separator, and the temperature was raised to 130 while stirring. ℃, after keeping warm for half an hour, add 18g xylene and keep warm, when the amount of water in the water separator no longer changes, stop the reaction. The material was lowered to room temperature, and after the layers were separated, the supernatant liquid, namely the solvent, was removed to obtain a reddish-brown water-soluble organic additive for use.

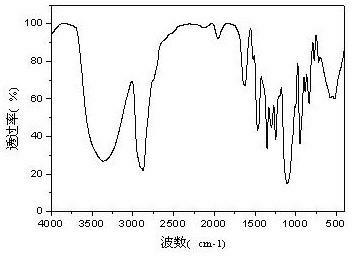

[0062] Embodiment 1 makes the infrared spectrum of organic additive a such as figure 1 , 3400 cm -1 ~3200cm -1 The strong and broad absorption peak at 2879 cm is mainly the stretching vibration peak of O-H -1 The strong absorption peak is CH 2 The stretching vibration peak of , ...

Embodiment 2

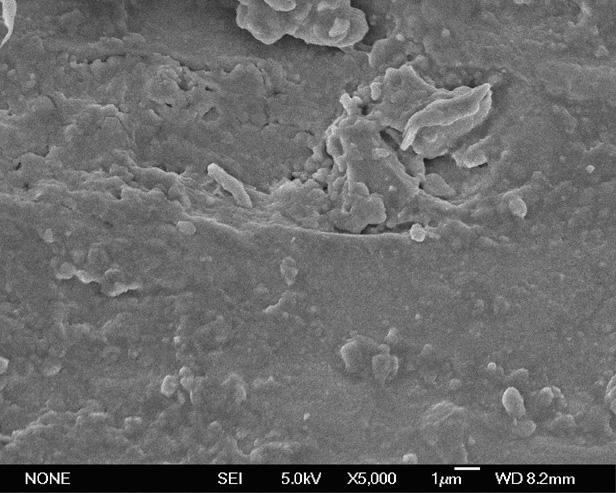

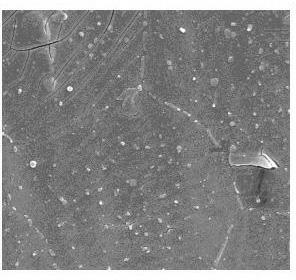

[0064] Example 2 : Preparation of titanium-zirconium / polyhydroxyl ester composite conversion coating on aluminum alloy surface

[0065] Weigh 5 g of fluotitanic acid (mass concentration 40% to 50%), 2.5 g of fluozirconic acid (mass concentration 40% to 50%), add 5 g of fluoboric acid, 4 g of boric acid and nitric acid (mass Concentration is 65%-68%) 6g, add a small amount of deionized water to dissolve and mix, then add ammonia water (mass concentration is 25%-28%) 2g, finally add polyhydroxy ester compound a3g prepared in Example 1, mix evenly, Dilute to 1 liter with deionized water to obtain a yellow transparent chrome-free treatment solution.

[0066] Weigh 50mL of the above treatment solution and dilute it to 1000mL, and adjust the pH value to 5.0, which is the treatment working solution for the titanium-zirconium / polyhydroxy ester compound conversion coating on the aluminum alloy surface.

[0067] Prepare the A6063 aluminum alloy test piece, immerse the aluminum allo...

Embodiment 3

[0085] Embodiment 3: the preparation of polyhydroxy ester compound b:

[0086] 26g of gallic acid, 48g of 1,4-butanediol, 0.2g of dibutyltin dilaurate, and 12g of butyl acetate were added to a four-neck round-bottomed flask with a stirring rod, a condensation device and a water separator, While stirring, the temperature was raised to 120°C. After keeping the temperature for half an hour, add 16g of butyl acetate and keep the temperature. When the amount of water in the water separator no longer changes, stop the reaction. The material was lowered to room temperature, and after the layers were separated, the supernatant liquid, namely the solvent, was removed to obtain a reddish-brown water-soluble organic additive for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polarization resistance | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com