Water dispersible granule formulated by azoxystrobin and cymoxanil and preparation method thereof

A technology of azoxystrobin and cymoxanil, which is applied in the field of preparation of water-dispersible granules, can solve the problems of endangering human health, environmental pollution, and high use cost, and achieve the effects of less environmental pollution, low control cost, and small use dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

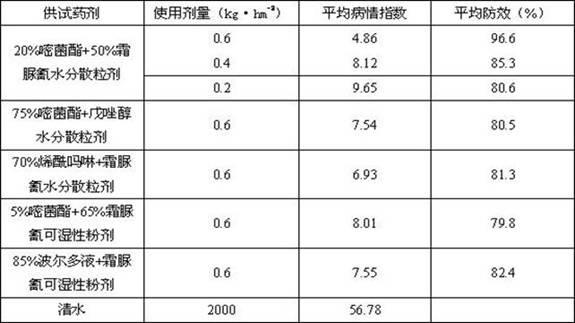

Examples

Embodiment 1

[0028] Weigh raw material components: azoxystrobin 60%, cymoxanil 15%, wetting agent T1004 3%, dispersant T2700 7%, disintegrant ammonium sulfate 4%, diluent kaolin 6%, disinfectant Foaming agent EP6703 2%, binder polyethylene glycol 72 2%, mix the above raw material components, stir evenly, and pulverize with a jet mill to obtain mother powder with a particle size of 400 mesh or more, and then add 30% of the raw material mass The deionized water is fully mixed with a mixing mixer, granulated with a granulator, then dried by a dryer, and passed through a sieve with 8 mesh and 40 mesh sieves to obtain a compound of 60% azoxystrobin and 15% cymoxanil water dispersible granules. After testing, the content of azoxystrobin is 60%, the suspension rate of azoxystrobin is 85%, the content of cymoxanil is 15.4%, the suspension rate of cymoxanil is 81%, the water content is 1.9%, the sieving (44μm sieve) is 98.3%, and the long-lasting foaming property (1 min) 14mL, the disintegration t...

Embodiment 2

[0030] Weigh raw material components: azoxystrobin 55%, cymoxanil 20%, wetting agent EFW 4%, dispersant D-425 6%, disintegrant sodium sulfate 5%, diluent diatomaceous earth 6%, defoaming agent EP6703 1%, binder carboxymethyl cellulose 2%, mix the above raw material components, stir evenly, and pulverize through a jet mill to obtain mother powder with a particle size of 400 mesh or more, and then add raw materials Deionized water with a quality of 30%, fully mixed with a mixing mixer, granulated with a granulator, then dried by a dryer, passed through a sieve of 8 mesh and 40 mesh by a sieving machine to obtain 55% azoxystrobin and 20% cream urea Cyanide compounded water dispersible granules. After inspection, the content of azoxystrobin is 55.6%, the suspension rate of azoxystrobin is 87%, the content of cymoxanil is 20.2%, the suspension rate of cymoxanil is 83%, the water content is 1.7%, the sieving (44μm sieve) is 99.1%, and the long-lasting foaming property (1min) 10mL, ...

Embodiment 3

[0032] Weigh raw material components: azoxystrobin 50%, cymoxanil 25%, wetting agent WP 3%, dispersant calcium lignosulfonate 7%, disintegrant sodium citrate 4%, defoaming agent Agent EP6703 1%, diluent light calcium 8% to make up. After the above raw material components are mixed evenly, they are pulverized by an airflow mill to obtain mother powder with a particle size of 400 mesh or more, then add deionized water with a mass of 30% of the raw material, fully mix with a mixing mixer, and granulate with a granulator, and then pass through Dried in a dryer, passed through a sieving machine with 8 mesh and 40 mesh sieves to obtain a water-dispersible granule compounded with 50% azoxystrobin and 25% cymoxanil. After testing, the content of azoxystrobin is 50.4%, the suspension rate of azoxystrobin is 86%, the content of cymoxanil is 25.5%, the suspension rate of cymoxanil is 82%, the water content is 1.5%, the sieving (44μm sieve) is 98.9%, and the long-lasting foaming property ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com