Preparation method and application of micro-enzyme reactor based on magnetic functionalized graphene oxide

A technology of enzyme reactor and graphene, which is applied in the direction of enzyme production/bioreactor, biochemical equipment and method, microbial measurement/inspection, etc., can solve the problem of high-efficiency loading of unfavorable enzymes, and achieve high reuse rate, heavy weight Good performance, simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

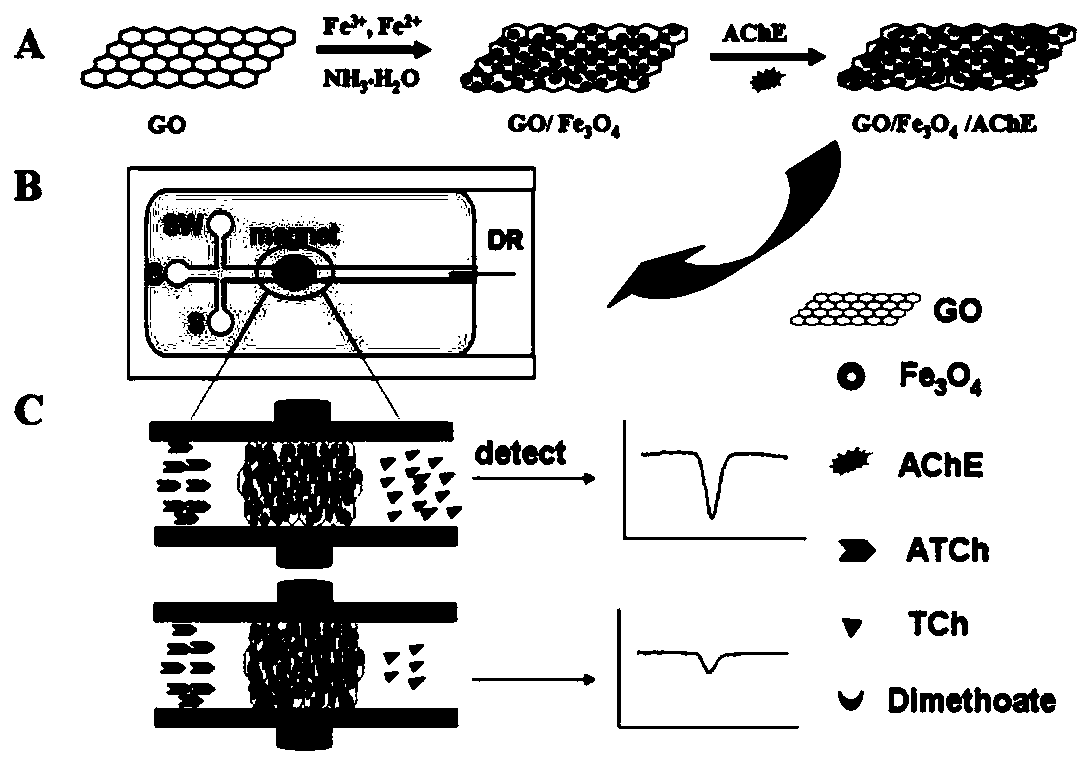

Method used

Image

Examples

Embodiment 1

[0025] Fabrication of PDMS chip: Using the SU-8 positive mold (Boao Biological Co., Ltd.) as a template, make a typical cross-shaped PDMS microfluidic chip channel, such as figure 1 shown. The specific production process is as follows: Take a certain amount of PDMS monomer and curing agent according to 10:1 (mass ratio), mix evenly, degas, pour on the SU-8 template, and cure at 70 oC for 2 hours. After cooling, peel off the PDMS chip containing the cross-shaped channel from the template, cut it into the desired shape with a blade, and punch holes in the buffer pool, sample pool and sample waste pool with a puncher to form a diameter of 3 mm holes. At the same time, using the smooth glass plate as a template, follow the same steps to prepare a PDMS chip without microchannels as a cover slip. The PDMS chip containing the cross channel and the PDMS cover sheet without the channel were ultrasonically cleaned with secondary water, methanol, and secondary water for 10 min, respect...

Embodiment 2

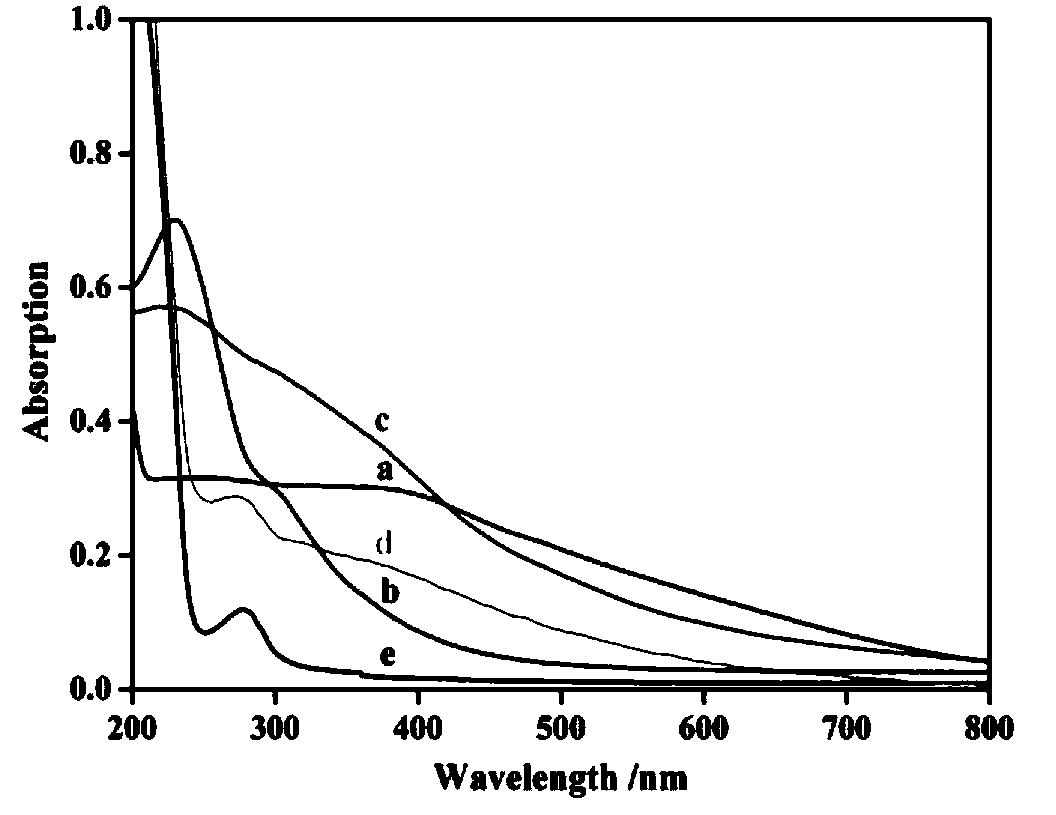

[0027] (1) Graphene oxide was prepared by the Hummers method: 0.5 g graphite powder and 0.5 g NaNO 3 Added to 23 mL to a concentration of 18 mol·L -1 H 2 SO 4 , slowly add 3 g KMnO 4 , after fully stirring and mixing, react in a water bath at 35 °C for 1 h to form a beige paste. Add 40 mL of water, stir at room temperature for 30 min, then dilute with water to 140 mL. Add 3 mL of 30% H by weight dropwise 2 o 2 , the solution turned from dark brown to bright yellow. Filter the product while it is hot, and wash the product by centrifugation with ultrapure water until the supernatant is neutral. -1 Centrifuge at 8000 rpm for 2 min, disperse the centrifuged product in ultrapure water, and -1 Centrifuge at a rotational speed for 2 min, disperse the centrifuged product in ultrapure water, and sonicate for 2 h to obtain a GO solution.

[0028] (2) Fe 3 o 4 Preparation of NPs-functionalized GO nanomaterials: Dissolve 40 mg of GO in 20 mL of ultrapure water and sonicate fo...

Embodiment 3

[0036] Based on GO / Fe 3 o 4 Application of microenzyme reactor prepared by / AChE in pesticide detection:

[0037] (1) Effects of detection potential, separation voltage, and substrate ATCh concentration on the performance of the microenzyme reactor

[0038] Image 6 A is the effect of the detection potential on the performance of the microenzyme reactor. When the detection potential is lower than -0.3 V, the peak current of TCh is small; as the detection potential increases, the peak current increases. When the detection potential is higher than +0.1 V, the peak current increases slowly; if the detection potential continues to increase, the background current also increases. In addition, the carbon fiber working electrode is easy to soften when subjected to high voltage. In order to prolong the service life of the working electrode and comprehensively consider the stability, reproducibility and signal-to-noise ratio of the detection signal, +0.1 V was selected as the detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com