Self-generating foam blocking removal agent for oil-water well and blocking removal process

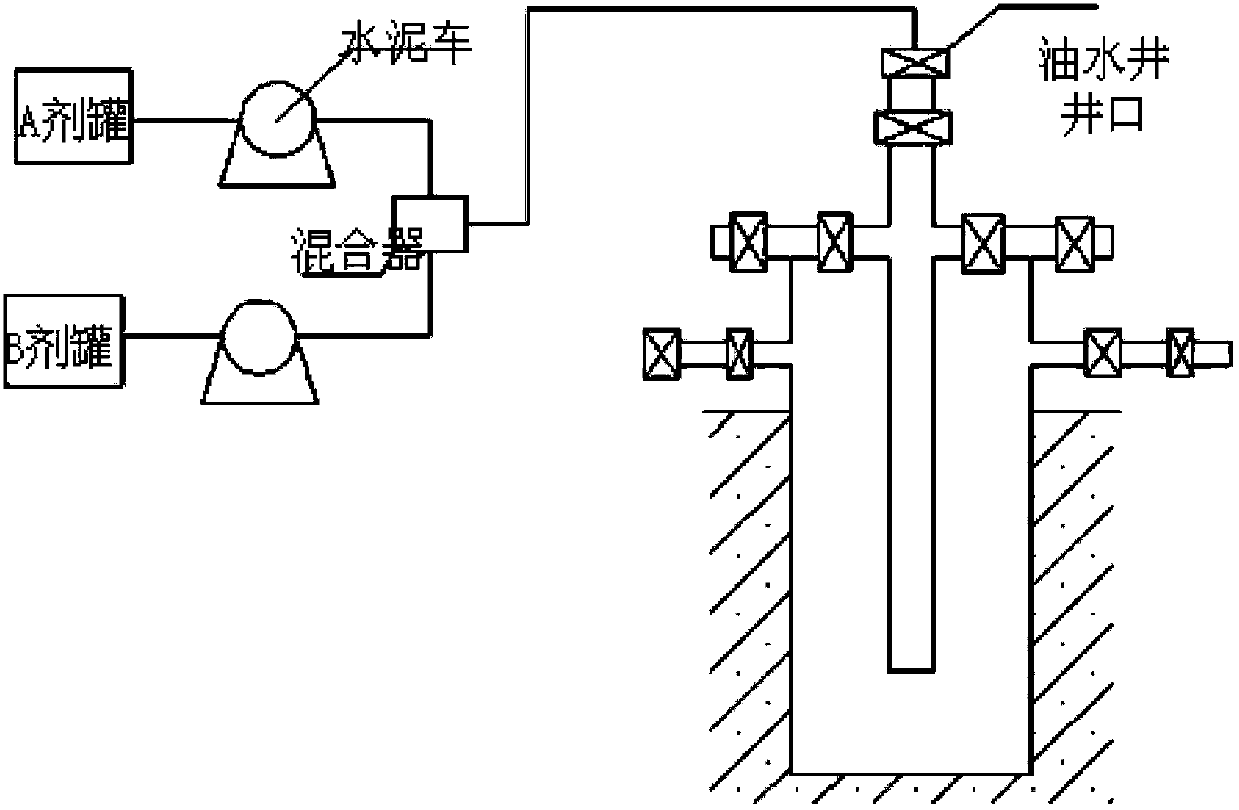

A technology of self-generated foam and blocking agent, which is applied in wellbore/well components, cleaning equipment, production fluid, etc., can solve the problems of limited sweeping surface, poor blocking removal effect, single blocking agent additive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] The plug-removing agent of the present embodiment is composed of A formulation and B formulation in a volume ratio of 1:1,

[0030] Among them, the mass percentage of the formulation of A agent is composed of: 10% HCL, 2% HF, 1% acetic acid, 1% citric acid, 0.3% quinoline benzyl ammonium chloride quaternary ammonium salt, 0.01% potassium iodide, 0.2% propynyl alcohol, 0.1% Naphthenic acid imidazoline acetate, 0.5% fatty alcohol polyoxyethylene ether sulfonic acid, 0.05% dodecyltrimethylammonium chloride, and the rest is water.

[0031] Among them, the mass percentage of the formulation of agent B is composed of: 5% ammonium bicarbonate, 1% potassium carbonate, 1.3% hydrogen peroxide, 0.02% sodium persulfate, 0.05% unsalted imidazoline oleate, 5 mg / L perfluorooctyl Sulfonic acid, 0.05% chloroacetic acid, 0.02% hydroxypropyl cellulose, and the rest is water.

[0032] A and B are mixed according to 1:1, and the corrosion rate is measured with reference to the standard SY / ...

Embodiment 2

[0036] The plug-removing agent of the present embodiment is composed of A formulation and B formulation in a volume ratio of 1:1.3,

[0037] Among them, the mass percentage of agent A formula consists of: 12% HCL, 2% HF, 3% sulfamic acid, 2% formic acid, 2% acetic acid, 2% succinic acid, 0.1% quinoline benzyl chloride quaternary ammonium salt, 0.5 % quinoline dichlorobutane quaternary ammonium salt, 0.4% tributylmethylammonium iodide, 0.7% butynediol, 0.1% oleic acid imidazoline acetate, 0.2% naphthenic acid imidazoline acetate, 0.6% Alkylphenol polyoxyethylene ether sulfonic acid, 0.5% fatty amine polyoxyethylene ether sulfonic acid, 0.05% octadecyl trimethyl ammonium chloride, 0.2% dodecyl dimethyl benzyl ammonium chloride, the rest For clear water.

[0038] Among them, the mass percentage of agent B formula is composed of: 2% sodium carbonate, 0.5% potassium carbonate, 4% ammonium bicarbonate, 1% hydrogen peroxide, 1.5% ammonium persulfate, 3mg / L N-ethyl, N-hydroxyethyl P...

Embodiment 3

[0043] The plug-removing agent of the present embodiment is made up of A formulation and B formulation in a volume ratio of 1.2:1,

[0044] Among them, the mass percentage of agent A formula is composed of: 10% HCL, 1% HF, 2% nitric acid, 2% formic acid, 4% succinic acid, 0.6% quinoline dichlorobenzyl quaternary ammonium salt, 0.5% tetramethyl iodide Ammonium, 0.3% propynyl alcohol, 0.4% naphthenic acid imidazoline acetate, 0.3% fatty alcohol polyoxyethylene ether sulfonic acid, 0.8% fatty amine polyoxyethylene ether sulfonic acid, 0.1% dodecyl dimethyl Benzyl ammonium chloride, 0.2% dodecyl trimethyl ammonium chloride, and the rest is water.

[0045] Among them, the mass percentage of B agent formula is composed of: 2% potassium bicarbonate, 6% ammonium bicarbonate, 3% hydrogen peroxide, 2% ammonium persulfate, 2mg / L N-ethyl, N-hydroxyethyl perfluorooctyl Sulfonyl ammonium phosphate, 2mg / L perfluorooctyl sulfonyl quaternary ammonium oxide, 0.1% unsalted oleic acid imidazolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com