Bacterial strain producing L-erythrothioneine and method of preparing the L-erythrothioneine

A technology of ergothioneine and mycelium, which is applied in fermentation engineering, biosynthesis of natural products, and biological resources, can solve the problems of low product yield and achieve the effect of high content and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Determination of the Fatty Acid Components of Pleurotus pachyrhiza CGMCC No.6232 Bacteria

[0037] (1) Measurement method

[0038] The fatty acid composition of the experimental strains was analyzed by using the Sherolock automatic bacterial identification system of the American MIDI (Microbial Identification) company.

[0039] (2) Preparation of reagents

[0040] Solution I: Dissolve 45g of sodium hydroxide in 150mL of methanol and 150mL of distilled water.

[0041] Solution II: Dissolve 190mL of concentrated hydrochloric acid and 275mL of methanol in 135mL of distilled water.

[0042] Solution III: Mix 200mL n-hexane and 200mL methyl tert-butyl ether evenly.

[0043] Solution IV: Dissolve 10.8 g of sodium hydroxide in 900 mL of distilled water.

[0044] Solution V: saturated sodium chloride solution.

[0045] (3) Extraction method

[0046] Use an inoculation loop to scrape an appropriate amount of culture from the surface of the PDA medium, put it int...

Embodiment 2

[0055] Embodiment 2: Determination of the G+C mol% content of Pleurotus pachyrhiza CGMCC No.6232 genomic DNA

[0056] Detection method: the G+C mol% content determination of strain genomic DNA uses the melting temperature (Tm) method, with Escherichia coli (E.coli K12, CGMCC1.365) as a reference control, and the instrument used is Lambda35 of PerkinElmer Company UV / VIS Spectrometer; use PerkinElmer's PTP-1Peltier System digital temperature controller to control the temperature. Proceed as follows:

[0057] (1) Dilute the DNA sample to be tested to OD with 0.1×SSC 260nm The value is between 0.3 and 0.4;

[0058] (2) First record the OD value at 25°C at a wavelength of 260nm, and then set the temperature rise program, starting from 65°C to 95°C, during which the temperature rises by 1°C per minute;

[0059] (3) The rise of OD value indicates the beginning of denaturation, record the cuvette temperature and OD value until the OD value remains unchanged, indicating that the den...

Embodiment 3

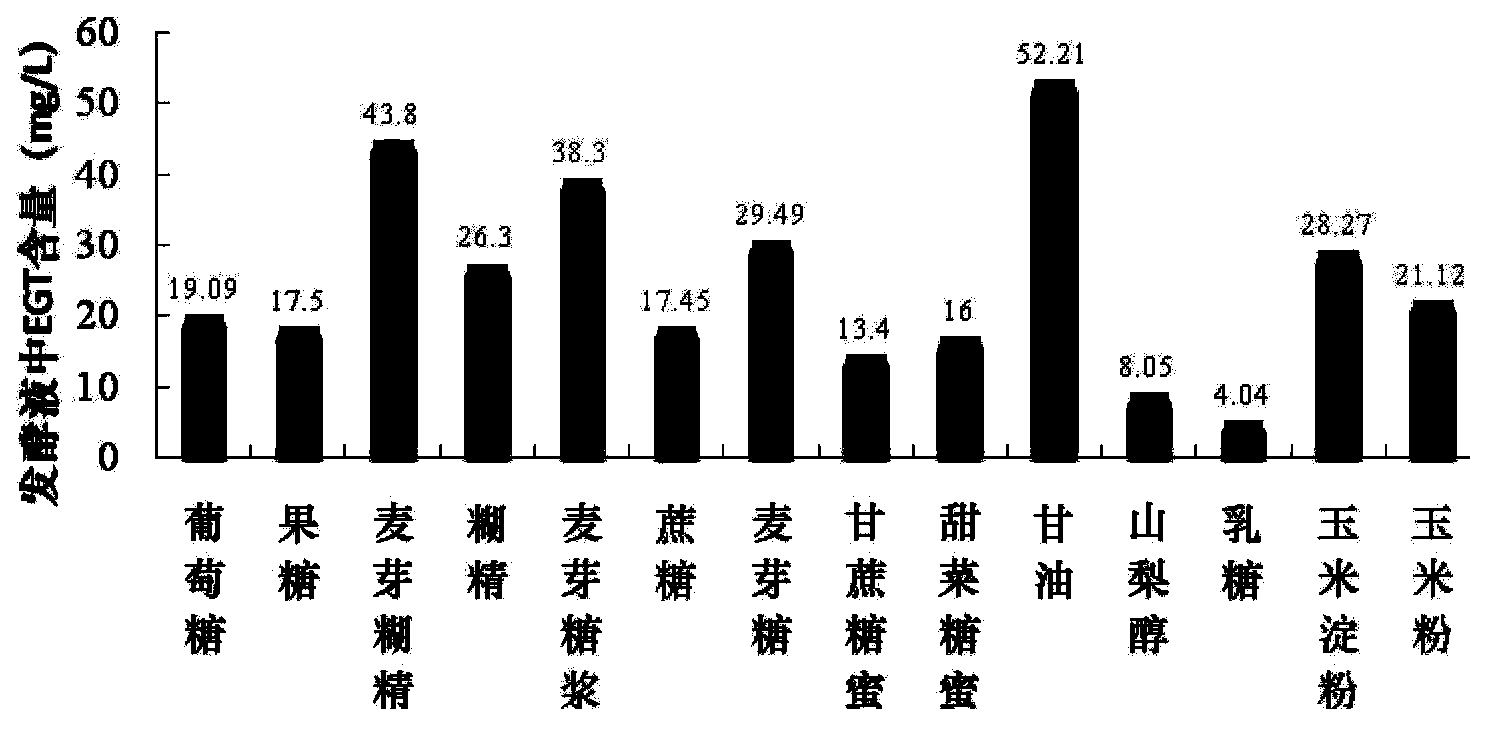

[0065] Embodiment 3: the ergothioneine fermentation of Pleurotus pleurotus CGMCCNo.6232

[0066] Liquid seed medium: corn flour (Meihekou Xingda Rice Industry Co., Ltd.) 30g / L, soybean meal powder (Beijing Zhongmian Ziguang Biotechnology Co., Ltd.) 15g / L, α-amylase (Beijing Soleibao Technology Co., Ltd.) Company) 54U / L, KH 2 PO 4 3g / L, MgSO 4 1.5g / L, the rest is water, sterilized at 121°C for 20 minutes, and the liquid volume in a 500mL Erlenmeyer flask is 150mL.

[0067] Fermentation medium: dextrin (Tianjin North Tianyi Chemical Reagent Factory) 20g / L, yeast extract powder (Angel Yeast Co., Ltd.) 15g / L, KH 2 PO 4 3g / L, MgSO 4 1.5g / L, the rest is water, sterilized at 121°C for 20 minutes, and the liquid volume in a 500mL Erlenmeyer flask is 150mL.

[0068] Inoculate each bottle of liquid seed medium with about 1 cm of 2 CGMCC No.6232 bacterial lawn of Pleurotus rugosa CGMCC No. 6232 was cultured at 25° C. on a shaker at 150 rpm for 4 days to obtain seed liquid. The seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com