A kind of thickening synergistic emulsifier and preparation method thereof

A technology of emulsifier and preparation process, which is applied in the preparation of thickening and synergistic emulsifiers, and in the field of thickening and synergistic emulsifiers, which can solve the problem of dust flying in wettable powder processing, serious environmental pollution, and poor drug efficacy, etc. problems, to achieve the effect of prolonged shelf life, long residence time, and small droplet particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

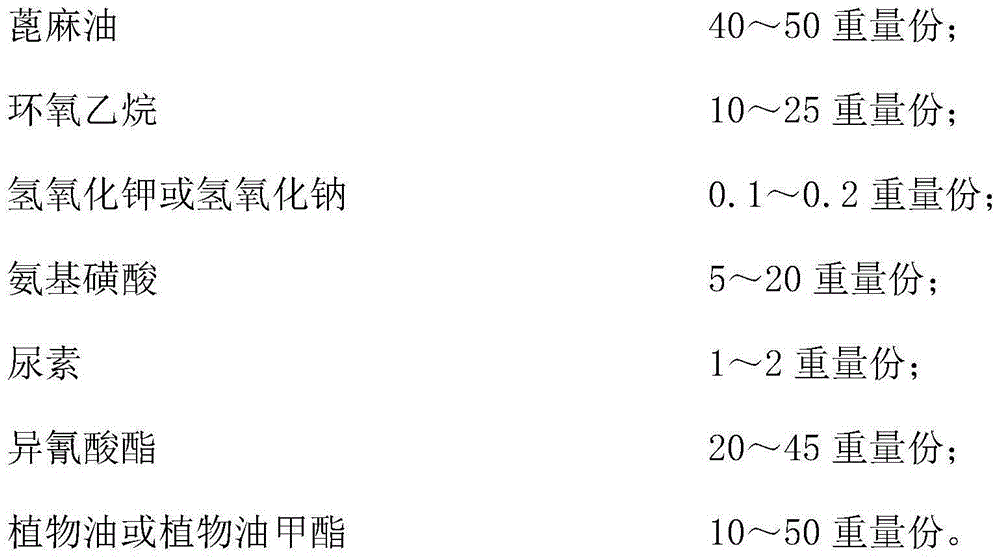

[0030] A thickening synergistic emulsifier embodiment 1 of the present invention comprises the following components, and each component is respectively by weight:

[0031]

[0032] Wherein, the isocyanate is a mixture of isophorone diisocyanate (IPDI) and diphenylmethane diisocyanate (MDI), and the vegetable oil is a mixture of peanut oil, rapeseed oil and corn oil.

[0033] The preparation method of this kind of thickening and synergistic emulsifier is as follows: add castor oil into the reaction kettle, then add potassium hydroxide, stir evenly, heat up to 130°C, then add ethylene oxide, and keep warm for 1 hour while stirring , then lower the temperature to 73°C, add sulfamic acid and urea to carry out the sulfonation reaction, the degree of sulfonation is controlled at 65-75%, the reaction time is 2h, then slowly add isocyanate dropwise, and continue to stir, after the dropwise addition is completed, the reaction temperature is 75°C Under the condition of heat preservat...

Embodiment 2

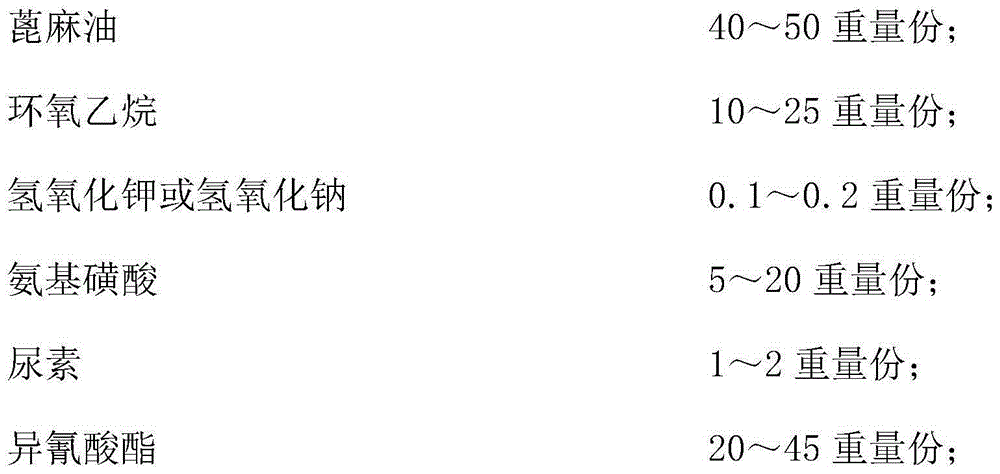

[0034] A thickening synergistic emulsifier embodiment 2 of the present invention comprises the following components, and each component is respectively by weight:

[0035]

[0036] Among them, the isocyanate is hexamethylene diisocyanate (HDI). Vegetable oil methyl ester is a mixture of methyl laurate, methyl palmitate, methyl oleate and methyl linoleate.

[0037]The preparation method of this kind of thickening and synergistic emulsifier is as follows: add castor oil in the reaction kettle, then add sodium hydroxide, after stirring evenly, heat up to 115°C, then add ethylene oxide, and keep warm while stirring for 1.5 h, then lower the temperature to 60°C, add sulfamic acid and urea to carry out sulfonation reaction, the sulfonation degree is controlled at 50-60%, the reaction time is 4.5h, then slowly add isocyanate dropwise, and continue to stir, after the dropwise addition is completed Heat preservation reaction at 55°C for 1.5h, and finally raise the temperature to 12...

Embodiment 3

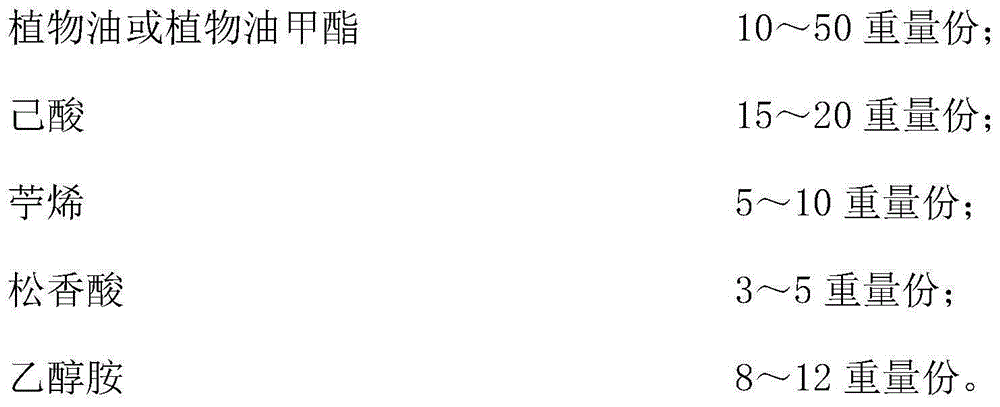

[0038] A thickening synergistic emulsifier embodiment 3 of the present invention comprises the following components, and each component is respectively by weight:

[0039]

[0040]

[0041] Wherein, the isocyanate is isophorone diisocyanate (IPDI), and the vegetable oil is a mixture of palm oil, coconut oil, peanut oil, rapeseed oil, and rice bran oil.

[0042] The preparation method of this kind of thickening and synergistic emulsifier is as follows: add castor oil into the reaction kettle, then add potassium hydroxide, stir evenly, heat up to 140°C, then add limonene and abietic acid, and pass through epoxy Ethane, keep stirring while keeping warm for 2 hours, then lower the temperature to 80°C, add sulfamic acid and urea for sulfonation reaction, after 0.5 hours of reaction, add ethanolamine to continue the reaction for 3 hours, control the degree of sulfonation at 70-80%, then raise the temperature to 150°C, add hexanoic acid, stir vigorously for 10 minutes, then slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com