Preparation method of cadmium telluride quantum dot sensitization nickel oxide photoelectrode

A technology of cadmium telluride quantum dots and electrodes, which is applied to electrodes, electrolysis process, energy input and other directions, can solve the problems of low cost, high price, low hydrogen production potential, etc., and achieves lower production cost, low cost and improved photocurrent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

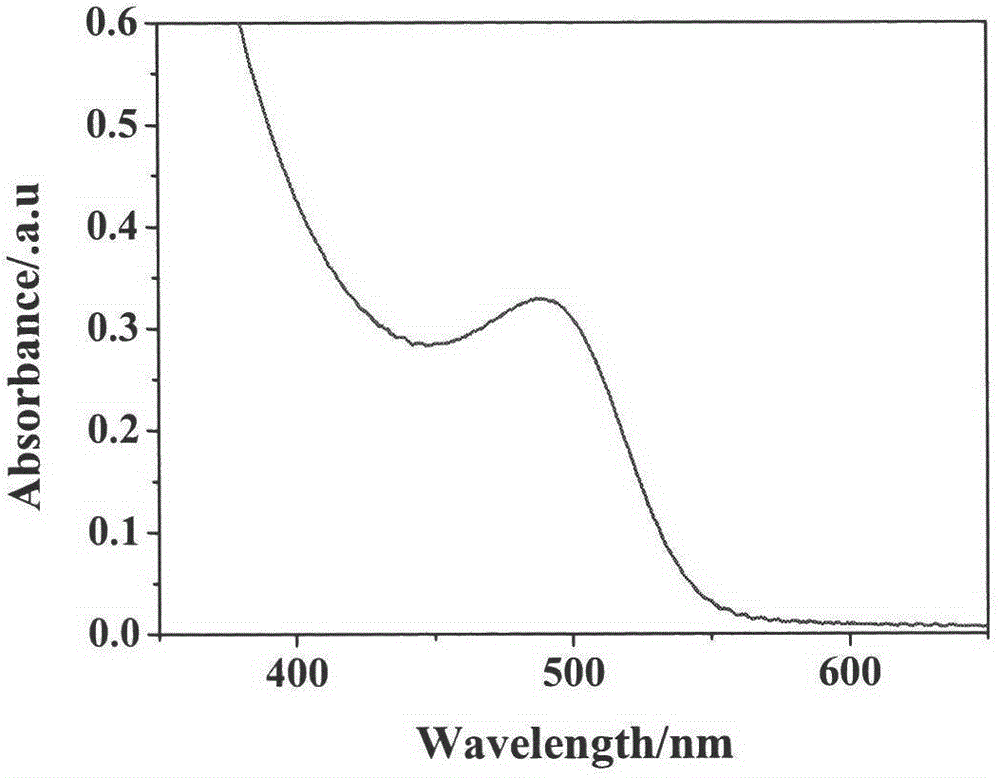

[0030] (1) Preparation of MPA-CdTe: Using tellurium powder as tellurium source, the molar ratio of sodium borohydride and tellurium powder is 2:1 to reduce tellurium powder to generate NaHTe, and use CdCl 2 2.5H 2 O is a cadmium source, mercaptopropionic acid is a stabilizer, and is dissolved in water and stirred at a molar ratio of Cd:MPA:Te=1:2.4:0.5, while adjusting the pH to about 11 with 1mol / L NaOH to obtain Cd Precursor. Add the prepared NaHTe and Cd precursor solution into the three-necked flask, stir and blow nitrogen for 20 minutes, add a condenser to the upper end of the three-necked flask, heat and reflux at 90°C, and the reaction time is preferably 5 hours. After the reaction is completed, wash with acetone , MPA-CdTe QDs were obtained after centrifugation.

[0031] (2) ITO conductive glass pretreatment: soak in acetone for 2 hours, soak in ethanol for 2 hours, then heat and reflux in KOH isopropanol solution for 15 minutes, take it out, wash it with deionized w...

Embodiment 2

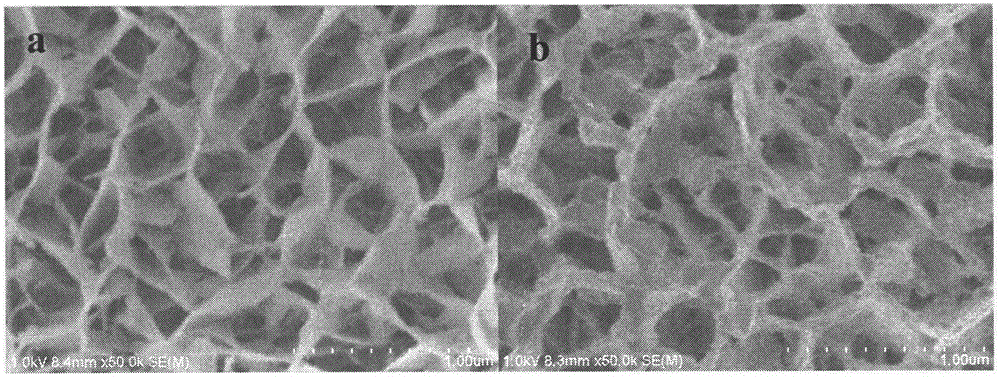

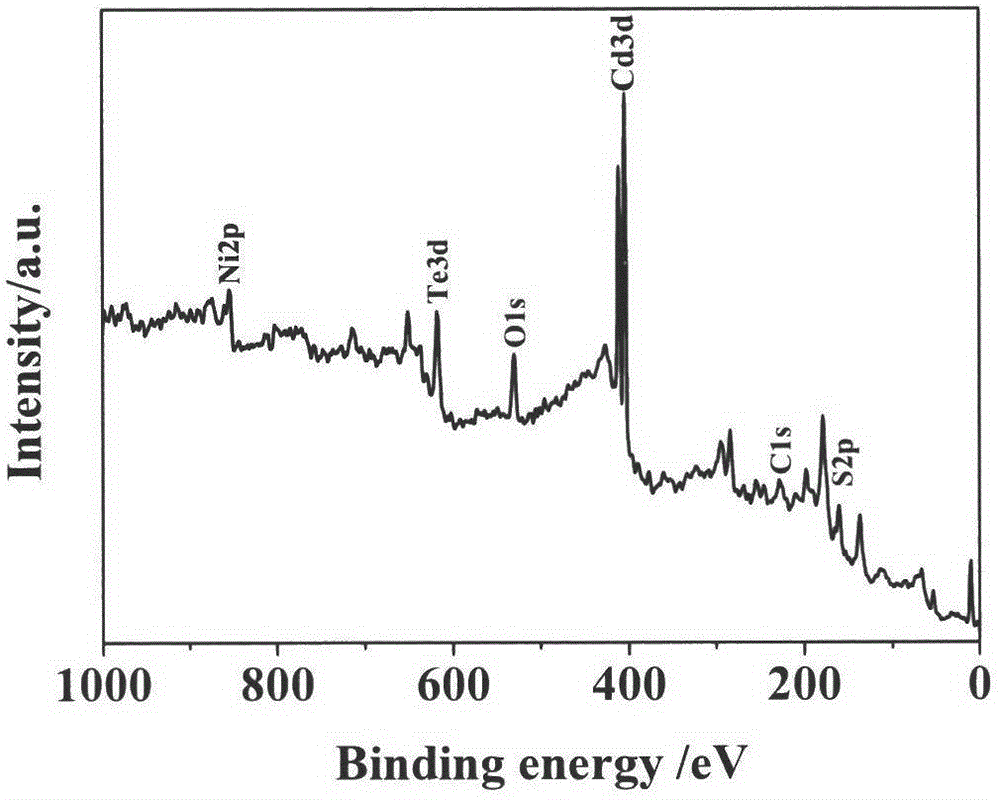

[0036] Using CHI600 electrochemical workstation, with NiO / CdTe electrode as the working electrode, Pt mesh electrode as the counter electrode, Ag / AgCl as the reference electrode, placed at 0.30mol / L C 6 h 12 N 4 , 0.20mol / L KCl, 0.10mol / L HCl buffer solution, add 1.0×10 -3 mol / L NiCl 2 ·6H 2O was used as a cocatalyst, and it was placed in a sealed nitrogen atmosphere, irradiated under a xenon lamp with a wavelength greater than 400nm, and the photoelectrocatalytic hydrogen production experiment was carried out at a voltage of -0.643V. After the reaction finishes, detect the hydrogen generated in the reaction with thermal conductivity-gas chromatography, and use X-ray photoelectron spectroscopy (XPS) (such as Figure 8 , shown in 9) and X-ray crystal powder diffraction (XRD) (as Figure 10 Shown) and other analyzes show that quantum dots and nickel salt self-assemble under light to generate a photoelectrode loaded with nickel salt.

Embodiment 3

[0038] Using CHI600 electrochemical workstation, with NiO electrode as the working electrode, Pt mesh electrode as the counter electrode, Ag / AgCl as the reference electrode, placed at 0.30mol / L C 6 h 12 N 4 , 0.20mol / L KCl, 0.10mol / L HCl buffer solution, add 1.0×10 -3 mol / L NiCl 2 ·6H 2 O was used as a cocatalyst, and it was placed in a sealed nitrogen atmosphere, irradiated under a xenon lamp with a wavelength greater than 400nm, and the photoelectrocatalytic hydrogen production experiment was carried out at a voltage of -0.643V. After the reaction, the hydrogen generated in the reaction was detected by thermal conductivity-gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com