A bioactive skull repair prosthesis and preparation method thereof

A bioactive, cranial technology, applied in the field of biomedicine, can solve problems such as difficulty in shaping titanium mesh, cerebrospinal fluid leakage and infection, and puncture the cortex of the skull, achieving reliable safety and effectiveness, and improving wettability and adhesion The effect of stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing the skull repair prosthesis as described above, the method comprising the following steps:

[0062] (1) Using selective laser sintering 3D printing technology, polyaryletherketone powder was used as raw material to prepare unmodified skull repair prosthesis layer;

[0063] (2) immersing the unmodified skull repair prosthesis layer in step (1) in the solution, and modifying under irradiation to obtain a modified skull repair prosthesis layer;

[0064] (3) Coating the nanofibrous film layer on the modified skull repair prosthesis layer in step (2).

[0065] As a preferred technical scheme, the preparation method of the above-mentioned skull repair prosthesis comprises the following steps:

[0066] (1) Using selective laser sintering 3D printing technology, polyaryletherketone powder is used as a raw material to prepare an unmodified skull repair prosthesis layer, and through holes are set on the unmodified skull ...

Embodiment 1

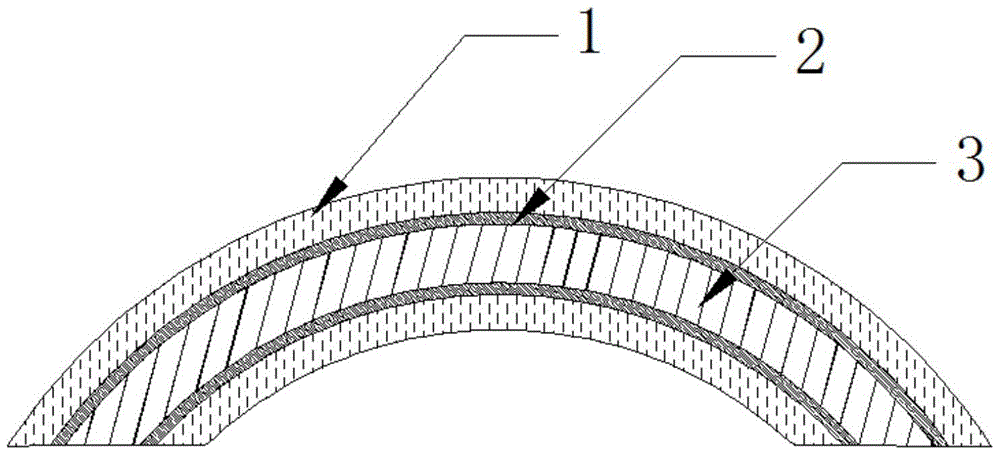

[0094] refer to figure 1 , the method for preparing 2-methacryloyloxyethyl phosphorylcholine modified polyether ketone ketone (PEKK) skull repair prosthesis is as follows:

[0095] (1) Use computerized tomography to scan the patient's skull with a scanning interval of 0.5 mm, store the scanned image in dicom format, read the data with Mimics software, segment and extract the skull data, and reconstruct the three-dimensional model of the skull And save it in stl format; then import it into 3-matic software, process the obtained 3D model, generate a cranial prosthesis that matches the original skull, and store it in stl format; import the stl file into selective laser sintering 3D printer (sPro60, 3D system), using implantable grade polyether ketone ketone (PEKK) powder as raw material to print the defect part of the skull repair prosthesis, that is, to obtain the unmodified skull repair prosthesis layer 3;

[0096] (2) The above-mentioned unmodified skull repair prosthesis lay...

Embodiment 2

[0099] refer to figure 1 , the method for preparing methacrylic acid-modified polyetheretherketone (PEEK) skull repair prosthesis is as follows:

[0100] (1) Use computed tomography technology to scan the patient's head with a scanning interval of 0.5mm, store the scanned image in dicom format, read the data with mimics software, segment and extract the skull data, and reconstruct the three-dimensional model of the skull , and then imported into 3-matic software to process the obtained 3D model to generate a skull repair prosthesis that matches the original skull and store it in stl format; import the stl file into a selective laser sintering 3D printer (sPro60, 3D system), using implantable grade polyetheretherketone (PEEK) powder as raw material to print the defect part of the skull repair prosthesis, that is, to obtain the unmodified skull repair prosthesis layer 3;

[0101] (2) The above-mentioned unmodified skull repair prosthesis layer 3 is immersed in the methacrylic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com