Geobacillus stearothermophilus for generating bioemulsifier and application thereof in high-pour-point oil exploitation

A technology of Geobacillus and biological emulsifier, which is applied in the field of biochemical industry and energy mining, can solve the problems of rapid rise of water content, limited development, low recovery degree, etc., achieve good emulsification performance and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The construction process and effect verification of the bacterial strain A-2 provided by the present invention.

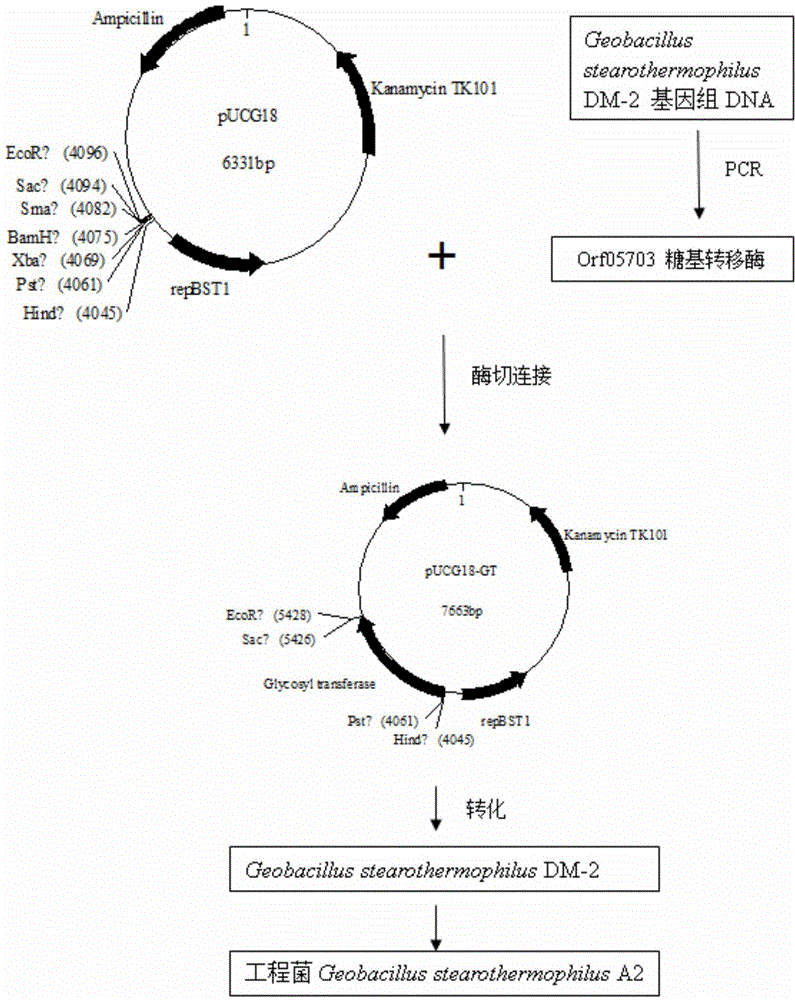

[0041] 1. Construction of expression vector

[0042] According to the complete gene cluster sequence of glycosyltransferase orf 5703 of Geobacillus thermophilia DM-2, using 6.0 software designed the upstream and downstream primers (see Table 1), and the primers were synthesized by Beijing BGI and purified by PAGE. Use the PCR reaction system and method listed in Table 2 to clone the 1359bp target gene fragment, and connect it to the genetic material preservation center derived from Bacillus after double digestion with SacI and PstI according to the reaction system and method in Table 3 On the pUCG18 vector of (BGSC), an expression vector pUCG18-GT with a size of about 7663bp was constructed, electrotransformed into Escherichia coli DH5α, and the plasmid was extracted.

[0043] Table 1 Primers used in experiments

[0044]

[0045] Table 2 PCR reaction ...

Embodiment 2

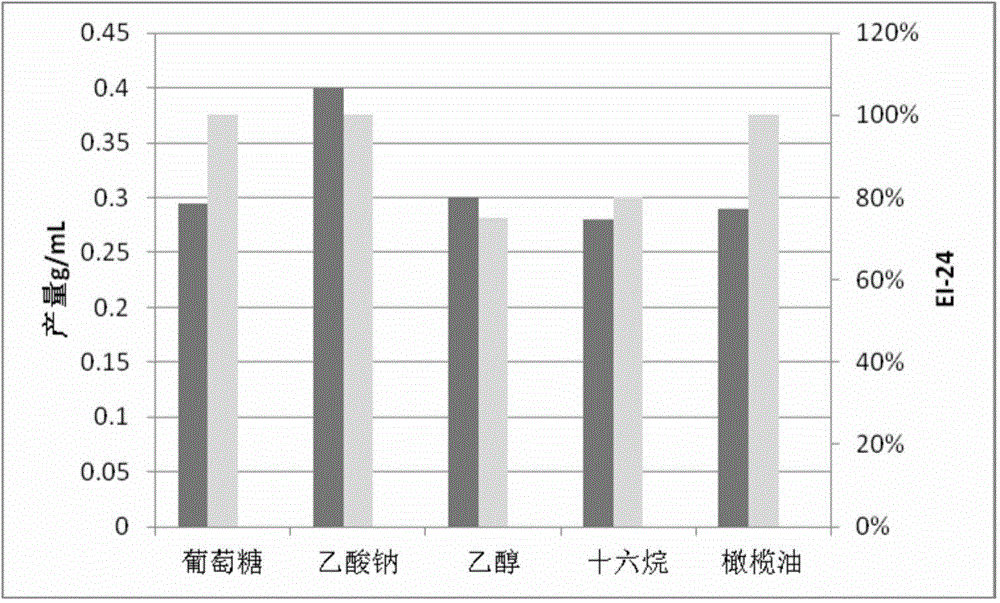

[0057] The situation that strain A-2 provided by the present invention utilizes 5 different carbon sources to produce emulsifiers.

[0058] The strain A-2 stored in the glycerol tube was activated, spread on LB plates, and cultured at 60°C overnight. Pick a single colony, inoculate into a 5mL LB test tube, incubate at 60°C, 200rpm for 12h. Then inoculate LB Erlenmeyer flask with 1% inoculation amount as seed solution, and cultivate to OD 600 0.5-0.8, that is, in the logarithmic phase, 5% was inoculated into the fermentation medium for emulsifier production, 60°C, 200rpm, and cultivated for 48h.

[0059] The fermentation broth was centrifuged at 4°C and 11000 rpm for 20 minutes to collect the precipitate, then 3 times the volume of pre-cooled acetone was added to the supernatant, and the refrigerator was placed overnight. Then it was centrifuged at 9000 rpm at 4°C for 10 minutes to collect the precipitate, that is, the coarse emulsifier, dissolved in an appropriate amount of ...

Embodiment 3

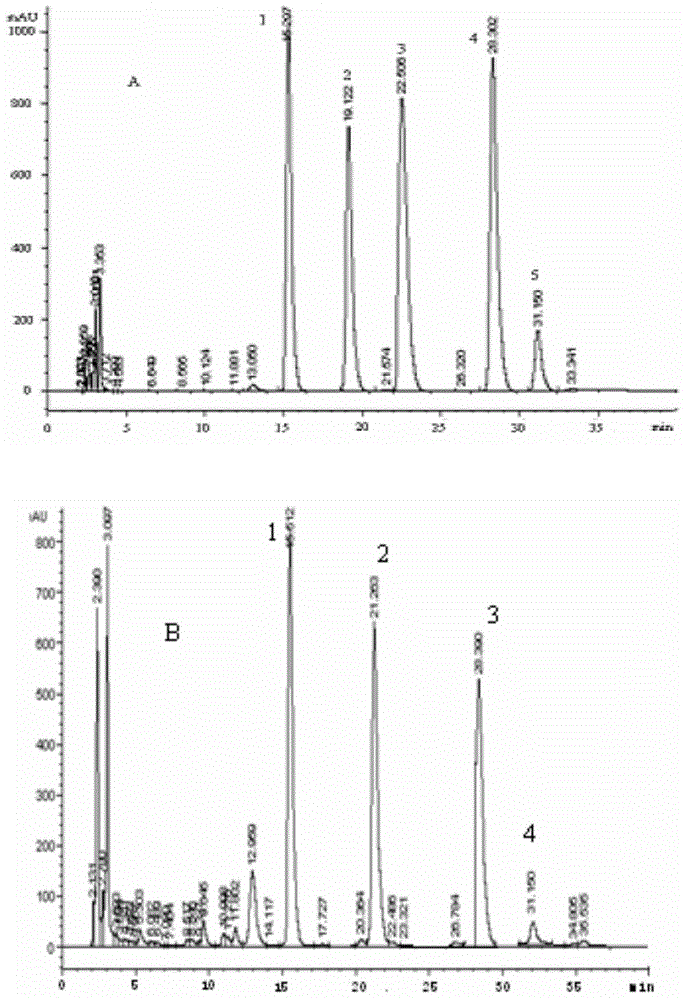

[0064] Component analysis of the bioemulsifier produced by the bacterial strain A-2 provided by the present invention.

[0065] 1. Qualitative sugar components

[0066] Carry out qualitative sugar analysis on the emulsifier sample extracted in Example 2 to detect whether sugar is contained in the sample. The specific experiment is as follows: the capillary is spotted on a silica gel plate and air-dried naturally. Evenly spread a thin layer of sulfuric acid-anthrone solution on the silica gel plate, air-dry it naturally, heat it in an oven at 105°C for 2 minutes, and develop the color. Further, the phenol-sulfuric acid method was used to detect the total sugar content in the samples, and glucose was used as a standard to prepare a standard curve. Weigh 10 mg of the sample, dilute to 100 mL with distilled water, prepare a 0.1 mg / mL test solution, measure it several times, and calculate the average value of the sugar content. Then the sample is subjected to acid hydrolysis, hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com