Preparation and application of RFID antenna-based inkjet conductive ink

A conductive ink and ink technology, applied in applications, inks, household utensils, etc., can solve the problems of uneven distribution, easy agglomeration, agglomeration and uneven distribution of nano-metal particles, and achieve simplified production process, simple experimental process, and substrate wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] At room temperature, dissolve 7.0g of sodium citrate in 100ml of deionized water, dissolve 10.2g of silver nitrate in 100ml of deionized water, and fully dissolve until it becomes a colorless and transparent solution. Put the silver nitrate solution in a constant burette, then slowly add it dropwise into the sodium citrate solution, stir while adding dropwise, a white precipitate will precipitate immediately. Continue to stir for 1 h after the dropwise addition is completed, then select a filter membrane with a pore size of 0.45 micron, vacuum filter, and wash twice with deionized water and ethanol respectively. After the suction filtration is completed, place the precipitate in an electric blast drying oven at 35°C and dry it in the dark for 12 hours to obtain a dried white solid, which is then ground into a white powder with a mortar.

[0027] Mix 10.0g of ethanol and 6.0g of ammonia water evenly, add 0.6g of silver citrate while stirring until completely dissolved to...

Embodiment 2

[0030] The preparation method of silver citrate is with embodiment one.

[0031] Mix 4.5g of ethanol, 1.5g of deionized water and 2.0g of ethylenediamine evenly, add 2.5g of silver citrate while stirring, until it is completely dissolved to obtain a brown transparent solution, add 0.5g of sodium citrate, 0.3g of carboxymethyl Base cellulose sodium, 0.5g succinic acid to adjust the viscosity and surface tension of the ink. Particle-free conductive ink can be obtained after filtering through a 0.2μm filter membrane. See attached figure 1 .

[0032] The ink has a viscosity of 5.28cp and a surface tension of 32.3dyn / cm. The ink was coated on the PET film, and after being sintered at a certain temperature for a period of time, the square resistance of the conductive film was measured to be 3.83Ω / □. Inkjet printing for RFID antennas.

Embodiment 3

[0034] The preparation method of silver citrate is with embodiment one.

[0035] Mix 7.0g of ethanol, 3.5g of ethylene glycol and 8.0g of sec-butylamine evenly, add 5.0g of silver citrate while stirring until completely dissolved to obtain a light yellow transparent solution, add 0.5g of sodium citrate, 0.15g of ethyl cellulose element, 0.3g malic acid to adjust the viscosity and surface tension of the ink. Particle-free conductive ink can be obtained after filtering through a 0.2μm filter membrane.

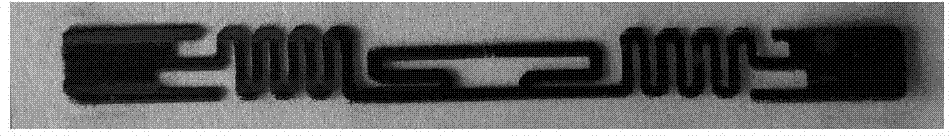

[0036] The ink has a viscosity of 5.83cp and a surface tension of 25.3dyn / cm. Using this ink to make an RFID antenna on PET by inkjet printing equipment. After sintering at a certain temperature for a period of time, the square resistance of the antenna was measured to be 1.49Ω / □ with the RTS-5 dual electric measuring four-probe tester. See attached figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com